Grade Recommendation of Tungsten Carbide Inserts

- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

NA

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

LIHUA

-

Model Number:

-

CNC Turning Tool Holder

-

Application:

-

Milling

-

Feature:

-

High Performance Cutting

-

MOQ:

-

10 Pcs

-

Package:

-

Original Plastic Box

-

Certifications:

-

ISO9001:2008

-

Advantages:

-

Sharp Cutting Edge

-

Processing:

-

Milling Machine

-

Material:

-

100%Tungsten Carbide(WC+CO)

-

Machining type:

-

general cuttng&interrupted cutting

-

Surface:

-

High Wear Resistance

Quick Details

-

Use:

-

Internal Turning Tool

-

Hardness:

-

HRC40-45

-

Coating:

-

PVD CVDor requirement

-

Warranty:

-

NA

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

LIHUA

-

Model Number:

-

CNC Turning Tool Holder

-

Application:

-

Milling

-

Feature:

-

High Performance Cutting

-

MOQ:

-

10 Pcs

-

Package:

-

Original Plastic Box

-

Certifications:

-

ISO9001:2008

-

Advantages:

-

Sharp Cutting Edge

-

Processing:

-

Milling Machine

-

Material:

-

100%Tungsten Carbide(WC+CO)

-

Machining type:

-

general cuttng&interrupted cutting

-

Surface:

-

High Wear Resistance

Product Description

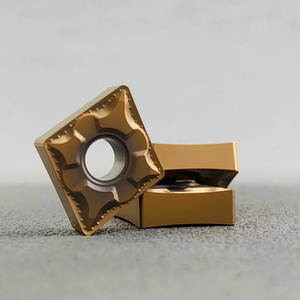

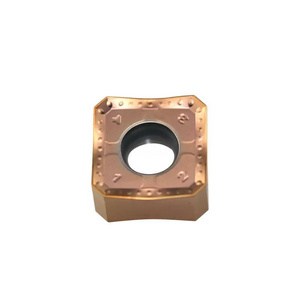

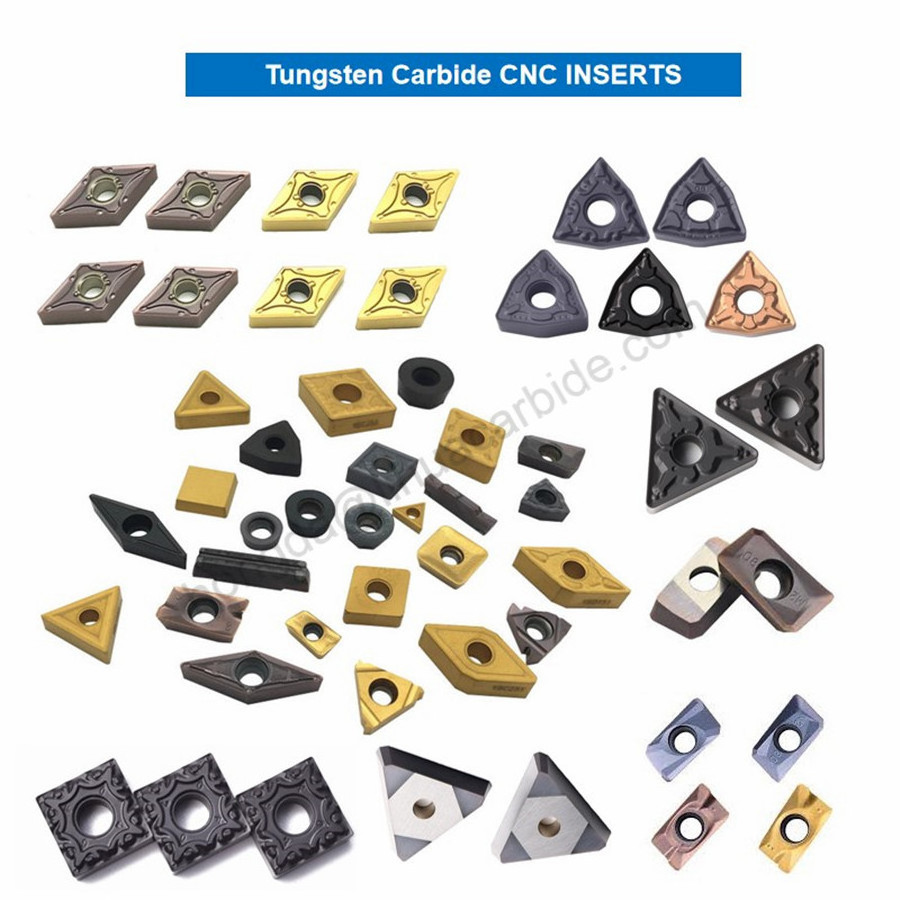

Carbide Cnc Milling/Turning Insert

China Manufacturer ISO VNMG Golden inserts CNC Cutting Tools Tungsten Carbide Insert

A

pplications

Tungsten Carbide cnc insert is used for cutting wood, metal, or other hard materials.

Can be hand-operated or power-driven.Our carbide inserts have used in surface processing of cast irons, colored metal and alloys, as well as non-metal materials for hard metal, carbide rough turn, rough planning, and precision milling.

|

Applicable Machine

|

For milling, turning, threading, grooving tool, cutting tools, etc.

|

|

Stock Level

|

For standard, have enough in stock

|

|

|

For non-standard, can be customized

|

|

Nonstandard order

|

Customized as request

|

|

Packing

|

10 PCS/plastic box

|

|

Coating

|

CVD or PVD coating

|

|

Processing

|

Finishing, Semi-finishing and Roughing

|

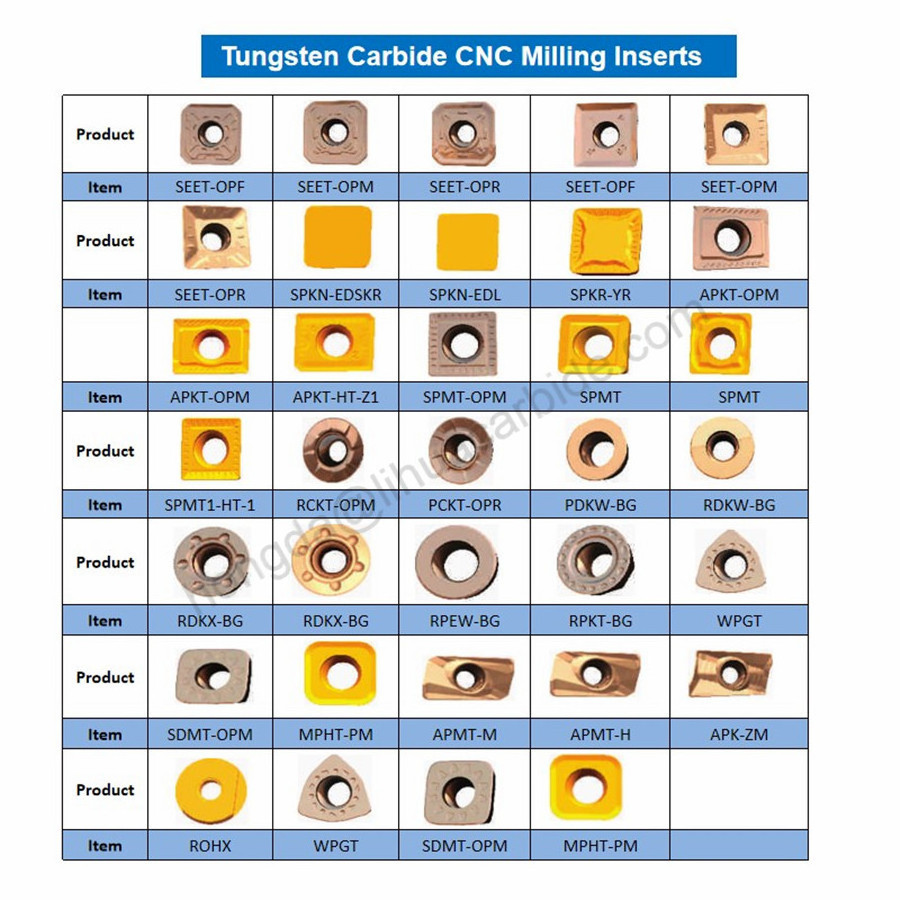

Carbide Milling Insert

Carbide Turning Insert

Grade

Title goes here.

|

Grade

|

Applications

|

|

YBC151

|

High wear resistance of the matrix and MT-TiCN, thick Al2O3 and TiN coating.

|

|

YBC152

|

Thick TiCN and Al2O3 coating

|

|

YBC251

|

tough matrix of good edge security and MT-TiCN, thick Al2O3 and TiN coating.

|

|

YBC252

|

Tough matrix of good edge security and MT-TiCN, thick Al2O3 and TiN coating.

|

|

YBC351

|

Tough matrix of good edge security and MT-TiCN, thick Al2O3 and TiN coating.

|

|

YBG102

|

nc-TiAN coating and fine-grained matrix.

|

|

YBG202

|

nc-TiAN coating and fine-grained matrix.

|

|

YBG205

|

Added abrasion resistance and high temperature rare elements ultrafine TiAlN based nano-coating. High layer hardness and excellent

resistance to high temperature provide effective protection for the cutting edge.

|

|

YBG302

|

nc-TiAN coating and flexible cemented carbide matrix.

|

|

YBM151

|

Special organizational structure and TiCN, thin Al2O3 and TiN coating.

|

|

YBM251

|

Good toughness and strength matrix and TiCN, thin Al2O3 and TiN coating.

|

|

YBM253

|

With the advance extra fine grain nanometer coating technology, match up with the high toughness gradient matrix.

|

|

YBD052

|

CVD coating(extra thick Al2O3 & thick TiCN), hard matrix.

|

|

YBD102

|

CVD coating (thick Al2O3 & thick TiCN) , hard matrix.

|

|

YBD152

|

CVD coating (thick Al2O3 & thick TiCN), hard matrix, it is anti-stripping.

|

|

YBD252

|

CVD coating (middle thick Al2O3 & thick TiCN), hard matrix.

|

|

YNG151

|

Uniform particle refining organizational ceramal alloy, homogenizing organizational & ring form phase structure, Strengthen bond

phase,grain boundary composition design.

|

|

YNG151C

|

Physics weather deposit (PVD) coating, high toughness ceramal matrix.

|

|

YD101

|

Fine particle hardness phase WC and bond phase Co.

|

|

YD201

|

Middle particle hardness phase WC and bond phase Co.

|

|

P/M

|

OTF Chip Breaker: Suitable for finishing steel and stainless steel material

|

OTM Chip Breaker: Suitable for semi-finishing steel and stainless steel material.

|

GM Chip Breaker: Suitable for semi-finishing steel and stainless steel material

|

OTR Chip Breaker:

Suitable for finishing stainless steel material |

|||

|

M

|

OMF Chip Breaker: Suitable for finishing stainless steel material

|

MF Chip Breaker: Suitable for semi-finishing stainless steel material

|

OMM Chip Breaker: Suitable for semi-finishing stainless steel material

|

|

|||

|

|

MSF Chip Breaker: Suitable for finishing stainless steel material

|

|

|

|

|||

|

K

|

|

General Chip Breaker: Suitable for cast iron semi-finishing cutting

|

|

Flat Chip Breaker: Suitable for cast iron roughing cutting

|

|||

|

S

|

OSF Chip Breaker: Suitable for hi-temp alloy finishing machining.

|

OSM Chip Breaker: Suitable for hi-temp alloy semi-finishing machining

|

|

|

|||

|

N

|

NL Chip Breaker: Suitable for aluminum and aluminum alloy material

|

|

|

|

|||

Recommend Products

Hot Searches