- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

Hot Product

-

Product name:

-

Herb Cutting Machine

-

Function:

-

Multifunctional

-

Keywords:

-

Ginseng Herb Leaf Shredder Slicer Machine

-

After-sales Service Provided:

-

Engineers

-

Capacity:

-

50-600/h

-

Material:

-

304/316L Stainless Steel

-

Feature:

-

Working Effeciency

-

Suitable for:

-

Chemical Fluid Equipment

-

Operation:

-

Hand Operate

-

Application:

-

Chemical Industries

Quick Details

-

Place of Origin:

-

Changzhou

-

Brand Name:

-

BRAVO

-

Weight (KG):

-

850

-

Marketing Type:

-

Hot Product

-

Product name:

-

Herb Cutting Machine

-

Function:

-

Multifunctional

-

Keywords:

-

Ginseng Herb Leaf Shredder Slicer Machine

-

After-sales Service Provided:

-

Engineers

-

Capacity:

-

50-600/h

-

Material:

-

304/316L Stainless Steel

-

Feature:

-

Working Effeciency

-

Suitable for:

-

Chemical Fluid Equipment

-

Operation:

-

Hand Operate

-

Application:

-

Chemical Industries

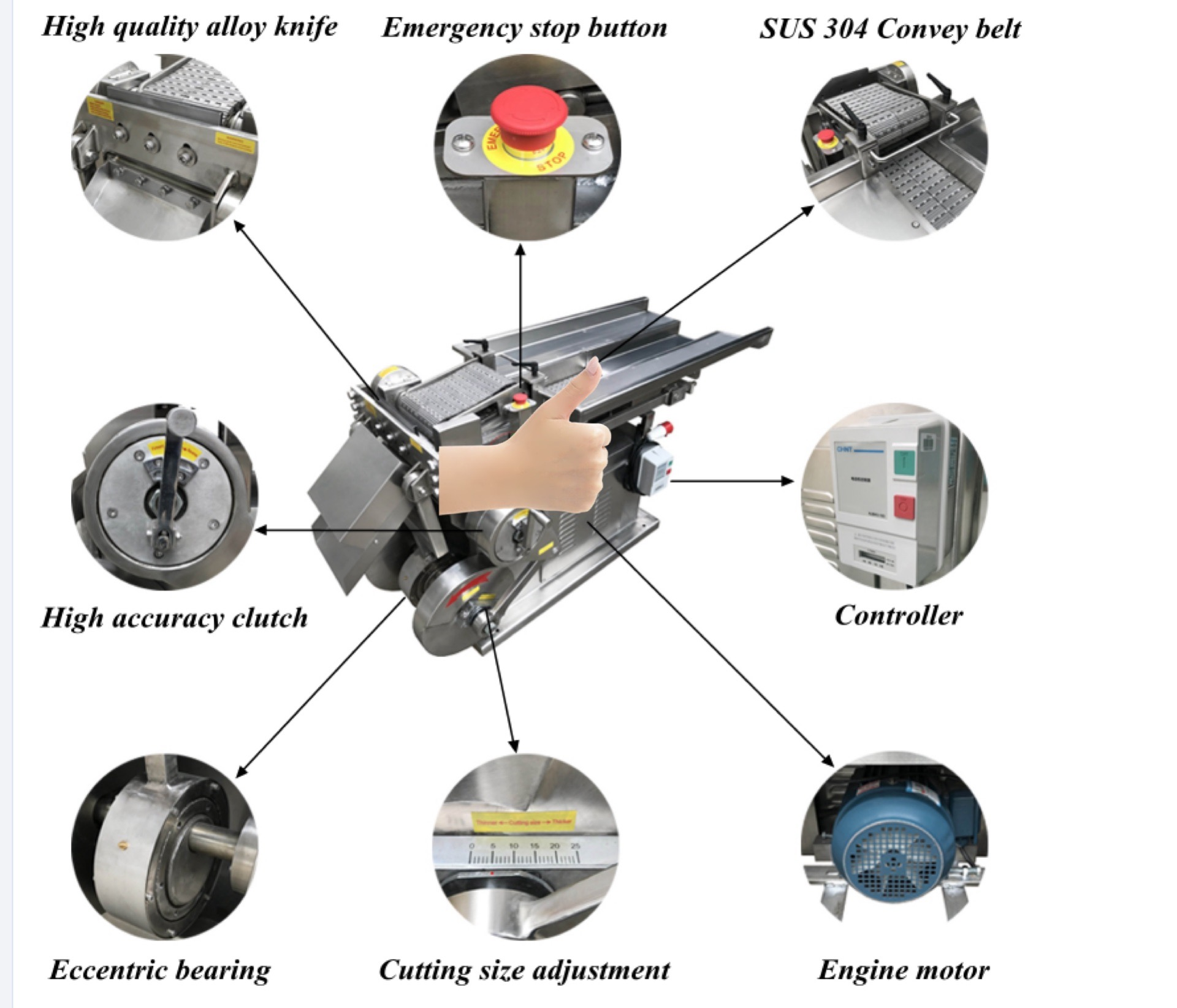

Cutting

medicine machine

This machine is suitable for the cutting of traditional Chinese herbal. It can be used for batch production and small batch production of Chinese herbal materials such as rhizomes, vines and leaf grasses. It can also be used for slicing and shredding of materials in food, aquatic products and tobacco industries.

Working principle

Since the power source is from the same motor, the movement of the transmission part and the cutting part is not only a separate system, but also a close and interrelated overall movement. When the eccentric wheel---five-star friction wheel--- gear--- the sprocket shaft is in the stepping process (feeding the herbal), and the knife holder is in the movement from the upper edge of the knife door to the uppermost position and then falling back to the upper edge, the entire knife door is opened, so that the herbal feeding movement can be completed. When the eccentric wheel--five-star friction wheel--gear--the sprocket shaft stops feeding and is in the motion gap (the rocker moves in the opposite direction, the five-star wheel disengages), the crankshaft moves from the upper position to the lower position, that is, the knife holder moves from the upper knife edge to the lower edge to complete the cutting.

Structure

This machine is composed of motor, shifting mechanism, tool holder, stepping and returning, adjustable knife frame machinery, etc.

Due to the advanced step feeding, the cut piece shape is even, and the feeding distance can be freely controlled. The bad

condition that caused the material to be squeezed will not happen. Due to the reasonable layout, the machine is easy to operate

and lightweight.

Due to the advanced step feeding, the cut piece shape is even, and the feeding distance can be freely controlled. The bad

condition that caused the material to be squeezed will not happen. Due to the reasonable layout, the machine is easy to operate

and lightweight.

Spare part-cutting knife

|

Model

|

WQJ-200

|

WQJ-300

|

WQJ-500

|

||

|

Knife door size (mm)

|

200×50

|

300×60

|

500×68

|

||

|

Cutting thickness (mm)

|

0.5-15

|

0.8-30

|

1-50

|

||

|

Capacity (kg/h)

|

50--600

|

100--1000

|

200--1500

|

||

|

Motor power (kW)

|

3

|

4

|

11

|

||

|

Dimensions (mm)

|

1800×800×1150

|

1900×900×1250

|

2000×1180×1400

|

||

|

Material of construction

|

304 SUS

|

|

|

||

|

Weight (kg)

|

850

|

1000

|

1500

|

||

|

Cutting speed (time/minute)

|

0-350

|

|

|

||

|

Cutting speed (time/minute)

|

380/50 or custom

|

|

|

||

Pcakaging and Shipping

Hot Searches