- Product Details

- {{item.text}}

Quick Details

-

Max. loading glass size:

-

2200*4200mm

-

PLC:

-

Siemens

-

machine power:

-

66KW

-

Machine Usage:

-

sandwich glass, bulletproof glass

-

heating type:

-

Stainless steel finned heating

Quick Details

-

Machine Type:

-

Glass Laminating Machine

-

Place of Origin:

-

China

-

Glass Application:

-

art glass laminating machine

-

Max. loading glass size:

-

2200*4200mm

-

PLC:

-

Siemens

-

machine power:

-

66KW

-

Machine Usage:

-

sandwich glass, bulletproof glass

-

heating type:

-

Stainless steel finned heating

Product Description

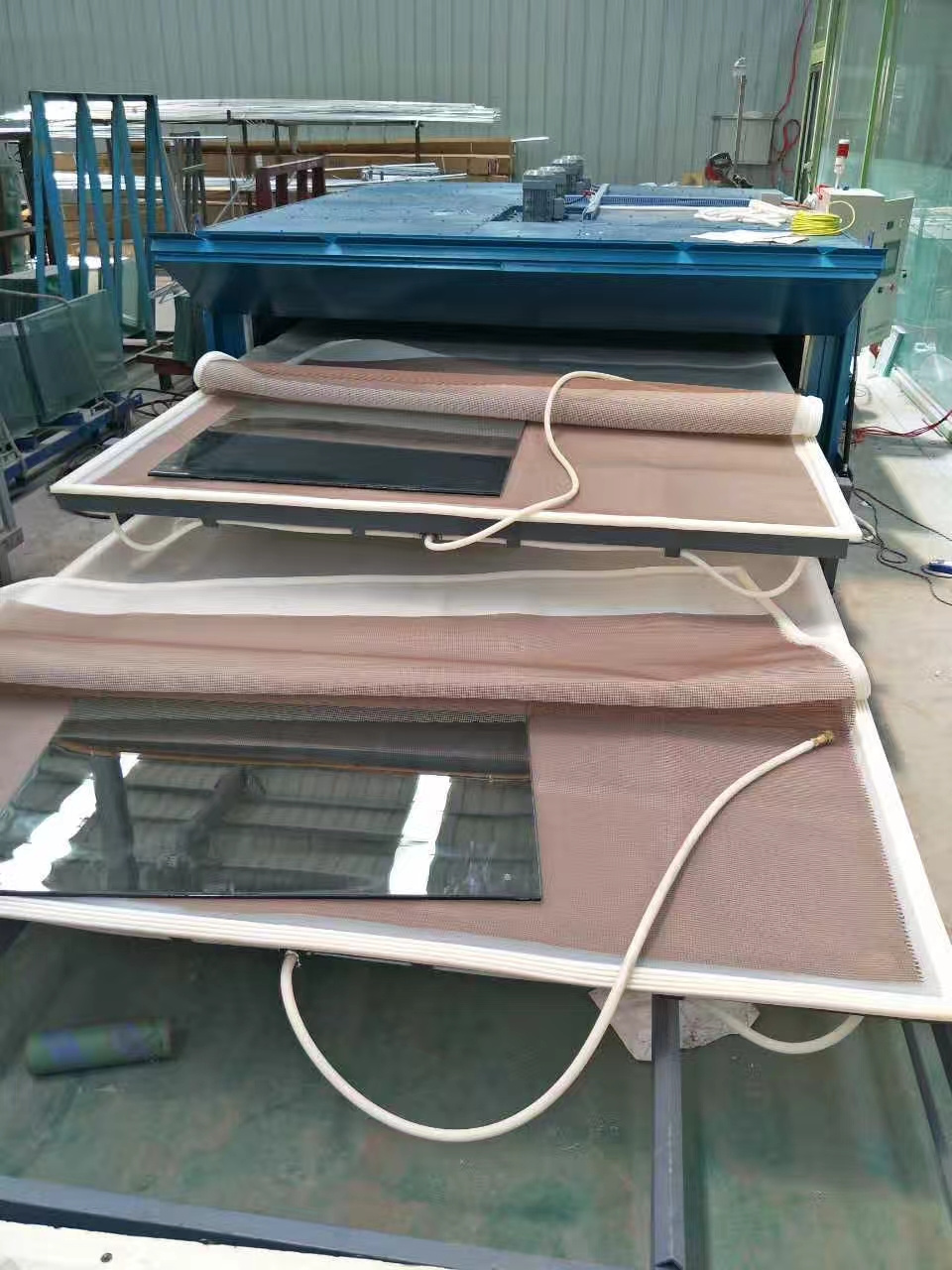

1. Machine Application

Glass laminating furnace, or called Glass Vaccum Heating and Laminating machine, is a kind of furnace developed by Lever Industry co.,ltd. By adopting vacuum bag principle, it can laminate two sheets of glass into one whole art glass through heating laminated materials and glass for perptizing under vacuum conditions.

This machine can laminated normal float glass with silk, cotton, paper,paintings, PET films or EVA films, to make various of beautiful art glass and decrotive glass.

It can also be used for laminating glass with PC sheets, soft sheet, to produce laminated glass, laminat ed glass, curved laminated glass, marble laminated, conductive glass, wired glass, tempered laminated glass, float laminated

glass, process laminated glass, LED glass, art glass , home appliance panel glass, tile glass, microcrystalline composite brick,etc.

This equipment can produce laminated glass without autoclave.

It is able to produce various laminated glass.

You can insert the silk, paper, plastic film, metal mesh, fibre or other films into normal glass Sheets in order to produce

decorative and functional laminated glass.

Controlled by PLC, it has the features of low consume, flexisble, accurate control, easy for operation.

This machine can laminated normal float glass with silk, cotton, paper,paintings, PET films or EVA films, to make various of beautiful art glass and decrotive glass.

It can also be used for laminating glass with PC sheets, soft sheet, to produce laminated glass, laminat ed glass, curved laminated glass, marble laminated, conductive glass, wired glass, tempered laminated glass, float laminated

glass, process laminated glass, LED glass, art glass , home appliance panel glass, tile glass, microcrystalline composite brick,etc.

This equipment can produce laminated glass without autoclave.

It is able to produce various laminated glass.

You can insert the silk, paper, plastic film, metal mesh, fibre or other films into normal glass Sheets in order to produce

decorative and functional laminated glass.

Controlled by PLC, it has the features of low consume, flexisble, accurate control, easy for operation.

|

No.

|

Name

|

Parameters

|

|

1

|

Rated voltage

|

380V

|

|

2

|

Oven Body dimensions

|

4700*2700*1900mm for reference only

|

|

3

|

Total dimensions

|

9400*2700*1900mm

(equipment size + lifting platform) |

|

4

|

Heating type

|

Stainless steel finned heating (copper row connection, uniform heat dissipation, long life)

|

|

5

|

Heating power

|

58KW

|

|

6

|

Total Power

|

66.6KW

|

|

7

|

Available Glass area size

|

2200mm*4200mm

|

|

8

|

Circulating fans

|

6 sets * 1.1kw/set

(multi-wing low noise and increased air volume suction type circulating fan) (Speed: 2800r/min Air volume: 1800-2400m3/h) Fan motor is copper wire motor |

|

9

|

Lifting Device

|

1 set

|

|

10

|

Control system

|

PLC control (Automatic start and stop, no need personnel to guard, automatic failure alarm) Vacuum detection, heating system detection, circulating air detection Schneider (Zhengtai) + Siemens PLC + Kunlun display |

Certifications

Packing & Delivery

|

Packaging

|

|

|

|

Size

|

4900 (L) *135 (W) * 1900mm (D)

|

|

|

Weight

|

1800KGS

|

|

|

Packaging Details

|

The normal package is film packing in container. If export to european countries, the wooden box will be fumigated.If container is too tigher, we will use pe film for packing or pack it according to customers special request.

|

|

Exhibition

Our Factory

Hot Searches