- Product Details

- {{item.text}}

Quick Details

-

Type:

-

One piece type

-

After Warranty Service:

-

Video technical support

-

Product name:

-

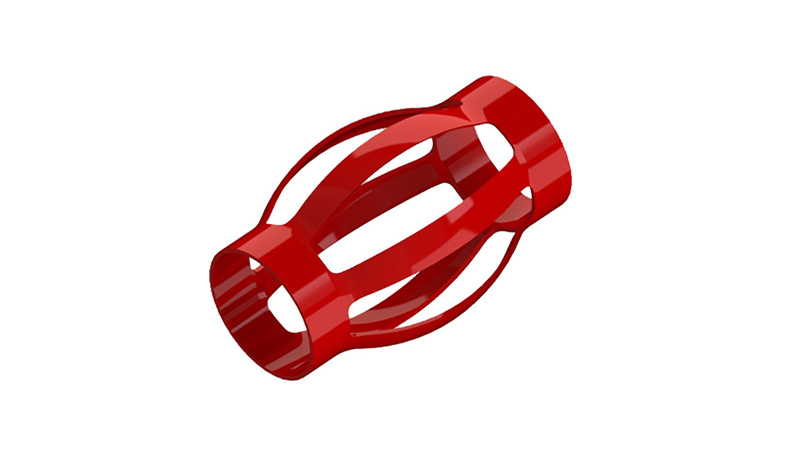

Cementing Casing Centralizer

-

Standard:

-

API 10D

-

Sample:

-

Acceptable

-

MOQ:

-

1pcs

-

Package:

-

Plywood Case

-

OEM:

-

Support

-

Material:

-

65Mn Steel

Quick Details

-

Brand Name:

-

Robust

-

Marketing Type:

-

Hot Product 2021

-

Core Components:

-

centrailzer

-

Type:

-

One piece type

-

After Warranty Service:

-

Video technical support

-

Product name:

-

Cementing Casing Centralizer

-

Standard:

-

API 10D

-

Sample:

-

Acceptable

-

MOQ:

-

1pcs

-

Package:

-

Plywood Case

-

OEM:

-

Support

-

Material:

-

65Mn Steel

Products Description

CASING CENTRALIZERS

|

Model (in)

|

Hooping In-Dia. (mm)

|

Hooping thickness (mm)

|

Hooping Height (mm)

|

Total Length (mm)

|

Max. Out-Dia. (mm)

|

Spring Pieces

|

|

5-1/2*8-1/2

|

142-148

|

3-5

|

90-120

|

650±50

|

225±5

|

5

|

|

7*9-5/8

|

181-186

|

3-5

|

90-120

|

650±50

|

255±5

|

6

|

|

7*8-1/2

|

181-186

|

3-5

|

90-120

|

650±50

|

235±5

|

6

|

|

8-5/8*12-1/4

|

223-228

|

3-5

|

90-120

|

650±50

|

330±5

|

8

|

|

9-5/8*12-1/4

|

250-255

|

3-5

|

90-120

|

650±50

|

330±5

|

8

|

|

10-3/4*12-1/4

|

274-276

|

3-5

|

90-120

|

650±50

|

330±5

|

9

|

|

13-3/8*17-1/2

|

342-347

|

3-5

|

90-120

|

650±50

|

450±5

|

11

|

|

18-5/8*24

|

476±1

|

3-5

|

90-120

|

600±50

|

610±5

|

12

|

|

20*26

|

510±1

|

3-5

|

90-120

|

600±50

|

660±5

|

12

|

|

Model (in)

|

Hooping In-Dia. (mm)

|

Hooping Thickness (mm)

|

Hooping Height (mm)

|

Total Length (mm)

|

Max. Out-Dia. (mm)

|

Spring Pieces

|

|

5-1/2*8-1/2

|

142-148

|

5-7

|

50-60

|

650±50

|

225±5

|

5

|

|

6*8-1/2

|

154-158

|

5-7

|

50-60

|

650±50

|

255±5

|

5

|

|

13-3/8*17-1/2

|

342-349

|

8

|

50-60

|

580

|

450±5

|

6

|

|

20*26

|

510-518

|

8

|

50-60

|

650±50

|

670±5

|

10

|

We always focus on good quality and excellentservice, comply strictly with international

trade practice, to be aworld-class petroleum equipment supplier. We

warmly Welcome our businesspartner to establish

long-term cooperative relationship with us.

Details Images

Casing centralizer as a cementing tool is applied in vertical, deviated and horizontal wells to centralize casing for improving the cementing quality. The cement could be concreted firmed between casing and borehole wall. It can be installed on casing joint or any position working with stop collar for centralizing. Our centralizer with API standard sizes range from 4-1/2” to 26” and surface is coated by powder baking or paint baking. The products have high tensile and yield strength, shock, impact and corrosion resistance performance.

Hinged bow spring centralizer is a traditional processed and economic centralizer, this kinds of centralizer is used in general vertical or slightly deviated wells .In the past, this kinds of bow spring centralizer is with the highest restoring force and the lowest starting force, so they are widely used in the drilling or cementing job, but now it is not the highest restoring force bow spring centralizer. It is simple way to increase the restoring force according to bow height. The higher bow, the more restoring force.

The bow of spring centralizer is made of 65Mn steel which is better tensile strength than general steel, but it is not up API standard, so we need process them by heat treatment in the high temperature and then annealing treatment in the cool water with special chemical material .What we do is to ensure the bow higher restoring force. This kinds of heat treated bow provides good centralization in the well when in fast running casing.

Their installation on the casing pipe is very convenient. It requires only the placement of the two assembled halves on the pipe and inserting the pin in the end collar hinge.

In order to increase anti-corrosion, we need use the special spring alloy steel, not simple 65Mn alloy steel according to customer's well environment. For the collar of bow spring centralizer, we use Q235 steel. It is not restrict requirement in API standard. What we do is to meet the restoring force according to API standard. The Hinged bow spring centralizers are available in size 4-1/2" to 26". We supply two kinds of hinged bow spring centralizer like welded centralizer and non welded centralizer.

The bow is open and packed in the wooden case with pins, lowering the shipment charges.

Case Presentation

Hot Searches