- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Kefa

-

Voltage:

-

380V, 380V 50Hz

-

Power:

-

20000

-

Dimension(L*W*H):

-

OEM

-

Weight:

-

kg, About 7T

-

Suitable to process:

-

Glazed Steel Coil

-

Width of the coil:

-

300mm

-

Rollers:

-

13rows

-

Thickness of the plate:

-

1.5-3mm

-

Productivity:

-

5--10m/min

-

Material of the cutting blade:

-

Cr12

-

Computer Control:

-

PLC

-

Processing precision:

-

Processing precision

Quick Details

-

Work Pressure:

-

OEM

-

Production Capacity:

-

High

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Kefa

-

Voltage:

-

380V, 380V 50Hz

-

Power:

-

20000

-

Dimension(L*W*H):

-

OEM

-

Weight:

-

kg, About 7T

-

Suitable to process:

-

Glazed Steel Coil

-

Width of the coil:

-

300mm

-

Rollers:

-

13rows

-

Thickness of the plate:

-

1.5-3mm

-

Productivity:

-

5--10m/min

-

Material of the cutting blade:

-

Cr12

-

Computer Control:

-

PLC

-

Processing precision:

-

Processing precision

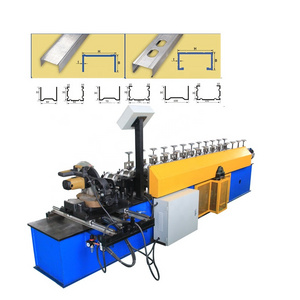

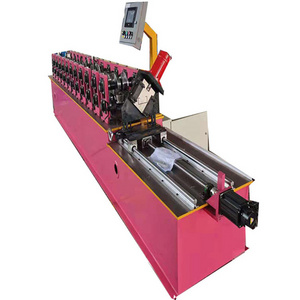

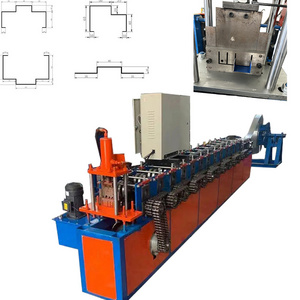

Features and Advantages of C Purlin Roll Forming Machine

Fully automatic continuous C profile purlin roll orming machine for both heavy and light-duty use.

Adopts changing spacers to make multi sizes profiles sections.

Inline flexible punching system integrated

Pre-cutting and Post cutting is optional: If need to produce many sizes, we can adopt pre-cutting to save cost and much

time on changing blades during change sizes.

If profile sizes are not so many, post-cutting can improve profile quality greatly.

Forming speed: 12-15 m/min

Certified with Multi-Patents: CE Certified, EUROPEAN quality standard.

For most hot & popular models, we have ready c purlin forming machines in stock for prompt delivery.

|

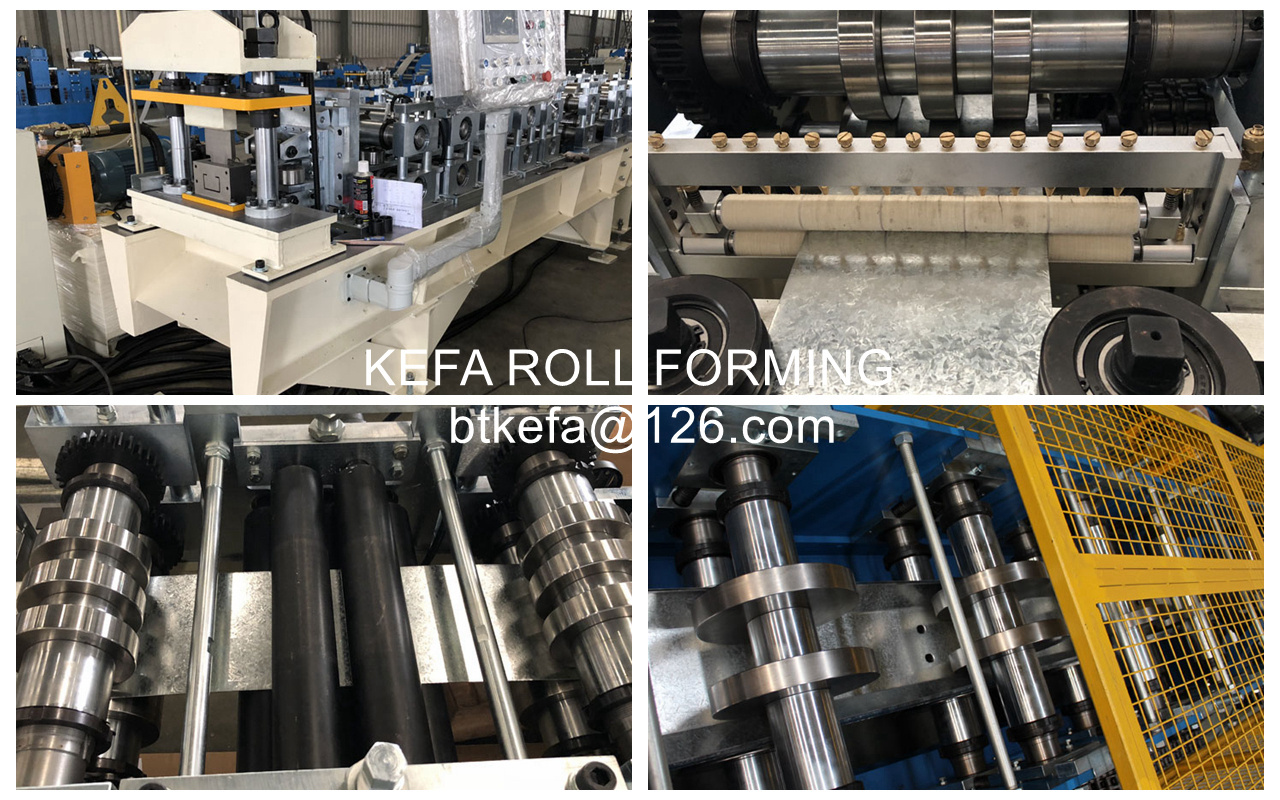

No. |

Name |

Unit |

Qty |

|

1 |

1.5T Manual decoiler |

set |

1 |

|

2 |

Main forming machine |

set |

1 |

|

3 |

PLC control system |

set |

1 |

|

4 |

Hydraulic pump station |

set |

1 |

|

5 |

Post cut |

set |

1 |

|

6 |

Electric motor |

set |

1 |

|

7 |

Output table |

set |

1 |

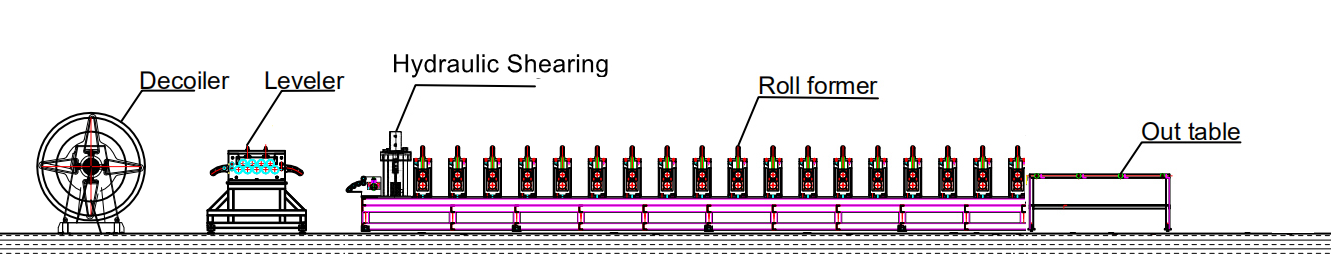

Working Flow of C Purlin Roll Forming Machine

Pre-cutting flow:

Decoiler(passive/auto)→Feeding and Guiding Table →leveling system→hole punching system(as profile requests)→pre-cutting to length → Roll Forming System →Output Manual Supporter/Auto Stacker(optional)

Post-cutting flow:

Decoiler(passive/auto)→ Feeding and Guiding Table →leveling system→hole punching system(as profile requests)→ Roll Forming System→ Post-Cutting to length(Hydraulic)→ Output Manual Supporter/Auto Stacker(optional)

Botou Kefa Roll Forming Machine Co., Ltd. is a manufacturer specializing in custom cold roll forming equipment and automatic production lines. We can manufacture hundred types roll forming machines,like Door frame machine,K type long span arching roof machine,automobile profile machine,Container house series machine,Steel silo series machine,Chicken cage series machine,Fence series machine,shelf series machine,highway guardrail series machine,coil leveling machine and all kinds of construction profiles.

Engineers and technicians are rich in experience of designing,developing and manufacturing of machines to provide customers with customized designs. We pay close attention to new trend of technologies.Our products are sold to many countries and regions around the world, and we have established long-term cooperative relationships with customers.

1. Quality Control

A. Every parts of machine is examed carefully without any omit.

B. Welcome to our factory to check machine

2. Installation & Training

A. We supply video to teach buyer how to install and operate machine

B. Welcome customers come to our factory, we are glad to teach you face to face.

C. Our technicians could come to customers' factory to install machine

3. After-sale service

A. One year warranty for parts and shipment of parts is free.

B. 24hours*365 days technical support online.

Our machines are working throughout our country and overseas.Few of our reputed clients have in fact given us their repeat orders for their production expansion.

Established in 2008 year,Kefa is a professional manufacturer specializing in the developing and manufacturing of cold roll forming machine,Silo Making Machine,Curve Profile Roll Forming Machine.

1.Construction Roll Form Machine:

Roof And Wall Panel,Floor & Roof Deck,Purlines,Elevators,Metal Building Beam,Metal Framework,Drywall Stud and Track,False Ceilings,Door & Window Frame,Door Skin,Shutter Door,C/Z/U/L Shaped Steel,Roof Flashings Roll,Arch Roof Panel,Container House

2.Automotive Roll Form Machine:

Carriage Panel,Bicycle/Motorbycle Wheel Rim,Tanker/Trailer Fender,Body Sides.

3.Agricultural Roll Form Machine:

Steel Silos,Greenhouse Pipe/Channels,Conveyor Cover,Layer Cage Frame,Vineyard Post,Corrugated Sheet Curver,

4.Industry Roll Form Machine:

Fence,Leveling/Slit & Cut to Length Line,sheet rolling bending,Cone rolling bending,Lock hoop,Pipe Arch Curve,Expansion Joint,Hand rail,Guard rail,pipe milling

5.Energy & Electricals

Solar Panels,Conduits,Light Fixtures,Pylons,Cable Trays,Cabinets,Box.

6.Logistics Roll Form Machine

Metal Containers,Upright,Shelving,Mezzanine Floors,Walkways,Scaffolding,Cold Rooms,Pallet Rack,

KEFA has been engaged in the metal roll forming industry for many years and devoted to developing some steel structure machines with a professional technology and reasonable price. In particular, we can provide professional service, high quality, through design and installation. At KEFA, our experience is our advantage.

FAQ

1.How to maintain the machine?

Answer: add mechanical lubrication equipment to chain, bearing and cutting slide every month. Add mechanical lubrication to the case every half a year.

2. Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications, using top brand name components.

3.How many workers to operate the machine?

A:Only 1-2 workers.

4. How to visit your company?

a.Fly to Beijing airport: By high speed train From Beijing Nan Station to Cangzhou West Station(1 hour), then we can pick you up .

b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou West station(4.5 hours), then we can pick you up.

5. What can you do if the machine broken?

Our machine's warranty period is 12months,if the broken parts can't be repaired,we can send the new parts to replace the broken parts for free,but you need pay the express cost yourself.if over warranty period,we can for to solve the problems via negotiation,and we supply the technical support for the whole life of the equipment.

6.How can I trust you that machines pasted testing running before shipping?

A: 1) We record the testing video for your reference. Or,

2) Please visit company and test machine if convenient.