pump filling and metering

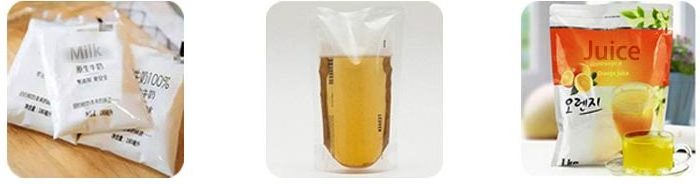

▷ Film sterilization, liquid material

sterilization

▷ The finished product bag is exquisite and reliable, hygienic and safe

▷ Assemble the photoelectric control device to ensure the integrity of the packaging bag pattern

▷ Automatically complete bag making, measuring, filling, sealing, cutting, counting,printing batch number

▷ The shell and material contact parts are made of stainless steel