- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

wd

-

Voltage:

-

380

-

Dimension(L*W*H):

-

20*2.2*1.8 meters

-

Weight:

-

3000 kg

-

Feeding width:

-

1200

-

Marketing Type:

-

classic

-

Name:

-

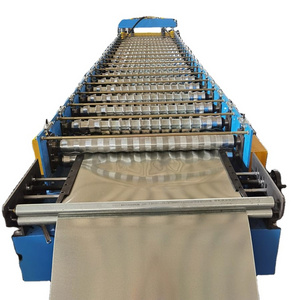

machine galvanized glazed ibr roof roll forming machine

-

Max.speed:

-

15m/min

-

Max.loading width:

-

1200mm/1000mm or according to your demands

-

Machine frame:

-

300H steel welded

-

Middle plate thickness:

-

14mm

-

Spacer:

-

seamless steel tube processing

-

Roller material:

-

45# steel forged

-

Shaft material:

-

70mm,45# steel forged

-

Motor power:

-

3kw

-

Cuter material:

-

Cr12

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

15 m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

wd

-

Voltage:

-

380

-

Dimension(L*W*H):

-

20*2.2*1.8 meters

-

Weight:

-

3000 kg

-

Feeding width:

-

1200

-

Marketing Type:

-

classic

-

Name:

-

machine galvanized glazed ibr roof roll forming machine

-

Max.speed:

-

15m/min

-

Max.loading width:

-

1200mm/1000mm or according to your demands

-

Machine frame:

-

300H steel welded

-

Middle plate thickness:

-

14mm

-

Spacer:

-

seamless steel tube processing

-

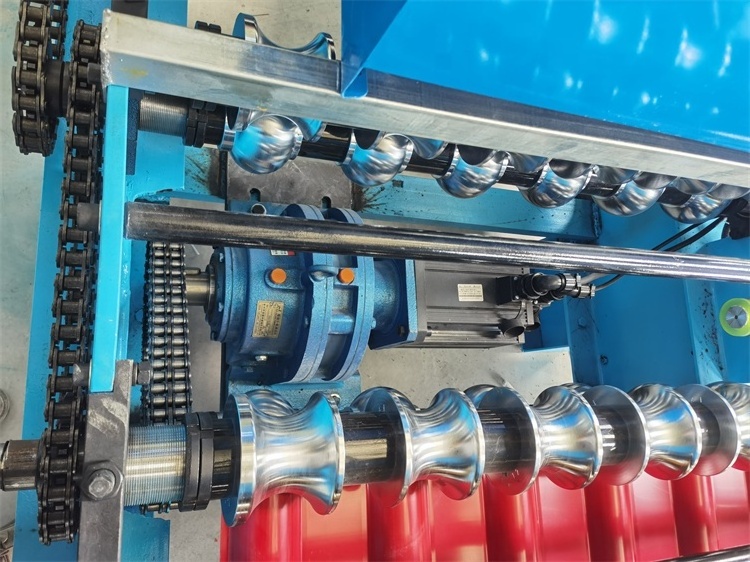

Roller material:

-

45# steel forged

-

Shaft material:

-

70mm,45# steel forged

-

Motor power:

-

3kw

-

Cuter material:

-

Cr12

Product Description

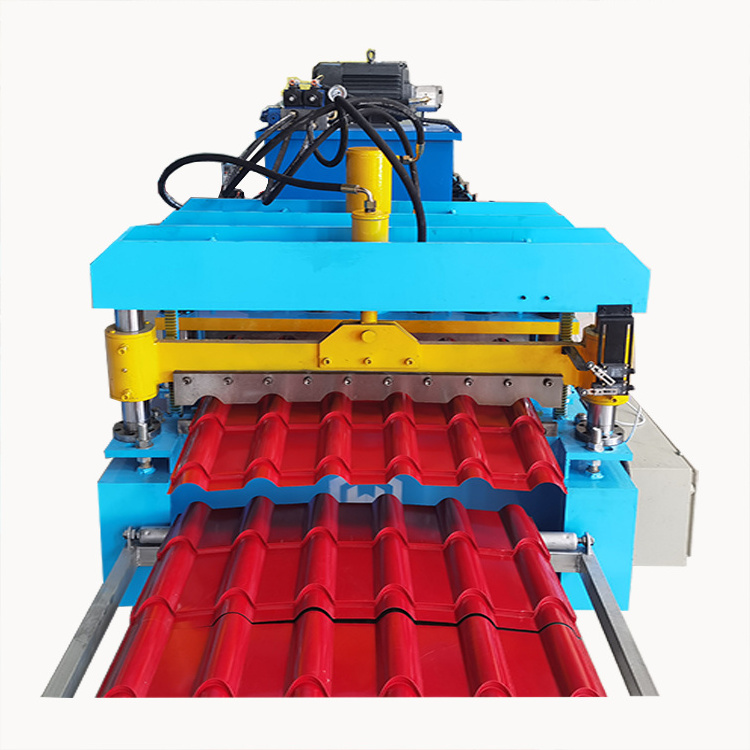

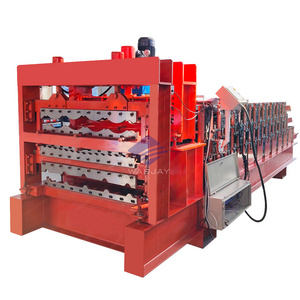

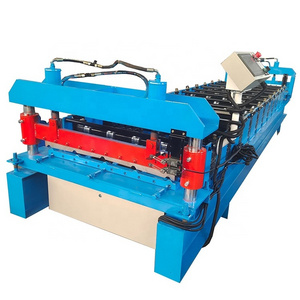

it is our company most popular products in building materials machine. For roof sheet, it include many type according to its different shape, popular type include corrugated tile roll forming machine, trapezoidal tile roll forming machine,glazed tile roll forming machine, ridge cap roll forming machine and other type profile panel roll forming machine.

Specification

|

Voltage

|

380v

|

|

Dimension(L*W*H)

|

20*2.2*1.8 meters

|

|

Weight

|

3000kg

|

|

Rolling thinckness

|

0.3-0.8mm

|

|

Max.speed

|

15m/min

|

|

Max.loading width

|

1200mm/1000mm or according to your demands

|

|

Machine frame

|

300H steel welded

|

|

Middle plate thickness

|

14mm

|

|

Spacer

|

seamless steel tube processing

|

|

Roller material

|

45# steel forged

|

|

Shaft material

|

70mm,45# steel forged

|

|

Motor power

|

3kw

|

|

Cuter material

|

Cr12

|

1.This roll forming machine can form smooth and beautiful metal roofing sheet without any scratch on surface

2.Roll forming process: uncoiler, roll forming, forming step effect, cut to length.

3.Fully Automatic Control System with PLC.

4.Easy operation: Set length and quantity on the control panel,machine will auto working 5.Customized your own roll forming machine, We can design the machine according to your specification and profile drawing.

More model for your choice

When you choose roll forming machine, you had better learn popular tile shape in local,also raw material is an important considering point, if do not have good supplier in local, we can assist your purchase in China together. we are professional factory in this area for many years, any demands please contact us at any time!

1200 double layer roofing sheet roll forming machine | metal roof roll forming machine | metal roof machine | trapezoidal sheet roll forming machine | roofing sheet making machine | wall sheet roll forming machine

1000 single layer roofing sheet roll forming machine | metal roof roll forming machine | metal roof machine | trapezoidal sheet roll forming machine | roofing sheet making machine | wall sheet roll forming machine

customized different machine according to your drawing ,contact us freely,design your own machine!!!!

Success Project

Packing & Delivery

South africa zinc trapezoidal steel sheet making machine galvanized glazed ibr roof roll forming machine

1)delivery from tianjin port

2)by whole container delivery

FAQ

South africa zinc trapezoidal steel sheet making machine galvanized glazed ibr roof roll forming machine

Q1.If machine can customize according to my drawing?

Yes dear, we can customize machine according to your tile drawing or photo.

Q2.If u can do train for my worker?

The machine has been installed and tested well before shipping. It is easy to operate.

Normally speaking, our customer follows the instruction book and can operate the machine well.?

You can also come to our factory to check the machine and learn how to operate before shipping. It only needs 2 hours and you can operate well.

Q3.How long we can get machine after payment?

Machines need about 20 working days after deposit payment received.

Q4.What is the package? Is it suitable for shipment?

Machine is large,need use container to delivey.

Q5.Payment term is ?

50% T/T as down payment, balance 70% by T/T before delivery. If others payment terms, we can discuss the details.

Q6.How long is the warranty for machines?

Machines warranty is 12 months after receive goods. in Warranty time,we can provide new free parts for changing.

Q7.Can you engineer come to our place to help with machine installation & commission?

Yes, our engineers are available to travel to your place. Round flight tickets & accommodation will be at your cost.

Hot Searches