- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

2100*1500*3100

-

Motor Power (kW):

-

15

-

Model Number:

-

J23-80T

-

Weight (T):

-

4.8

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

-

Product name:

-

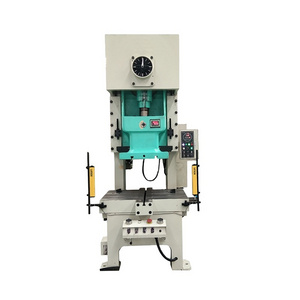

Round coin mechanism power press/metal stamping machine

-

Color:

-

Customizable

-

Application:

-

Metal process

-

Material:

-

Aluminum, SS, MS, etc

-

Safety protection:

-

Photoelectric protection

-

Electrical:

-

CHNT

-

Body:

-

Cast

-

CNC feeding system:

-

Available

-

Worktable:

-

Inclinable

-

Nominal Force (kN):

-

800

-

Certification:

-

CE ISO

Quick Details

-

Slide Stroke (mm):

-

120

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Durmark

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

2100*1500*3100

-

Motor Power (kW):

-

15

-

Model Number:

-

J23-80T

-

Weight (T):

-

4.8

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

-

Product name:

-

Round coin mechanism power press/metal stamping machine

-

Color:

-

Customizable

-

Application:

-

Metal process

-

Material:

-

Aluminum, SS, MS, etc

-

Safety protection:

-

Photoelectric protection

-

Electrical:

-

CHNT

-

Body:

-

Cast

-

CNC feeding system:

-

Available

-

Worktable:

-

Inclinable

-

Nominal Force (kN):

-

800

-

Certification:

-

CE ISO

Round coin mechanism power press/metal stamping machine

J23 series op

en press is a sheet metal Universal presses for shearing, punching,

blanking, bending and shallow drawing work. Usually used for ( communications,

computers

, household appliances, furniture, vehicles, (cars, motorcycles, bicycles)

metal parts stamping and forming).

|

No

|

Name

|

J23-80T

|

|

1

|

Nominal force(KN)

|

800

|

|

2

|

Nominal force stroke(mm)

|

5

|

|

3

|

Slider stroke(mm)

|

115

|

|

4

|

Slider stroke times(time\min)

|

45

|

|

5

|

Maximum height for die loading

|

410

|

|

6

|

Adjustment range for die loading height

|

60

|

|

7

|

Distance between slider center line and the fuselage

|

280

|

|

8

|

Worktable size

|

500*750

|

|

9

|

Work table blanking hole size

|

D200*250*375

|

|

10

|

Slider bottom size

|

250*300

|

|

11

|

Shank hole size

|

D60*Depth100

|

|

12

|

Distance between columns(mm)

|

360

|

|

13

|

Bolster thickness(mm)

|

90

|

|

14

|

Tilting degree(degree)

|

20

|

|

15

|

Motor(kw)

|

7.5

|

Main F ea tures

1, With foundry structure for better vibration resistance.

2, Adopt horizontally placed crankshaft, external gear is open and easy for maintenance.

3, The good rigidity of Casting box structure slider.

4, Built-in block collapsed overload protectio

n device, the structure is simple, if slider after

overload,

fuse collapsed destroyed to protect the machine and mold from damage.

5, Four elongated triangular rail, easy for adjustment.

6, Adopts hands and foot switch operation buttons design, it's easy to activate continuous,

single and adjustment practices.

7, Compatible with the corresponding punch automatic feeding system, which having a feeding

error detection, pre-cut and pre-breaking device, low cost and high efficiency.

Pa

ckag

i

n

g Details:

Plastic

film, wooden package, or as requirement.

Delivery

Detail:

15 days

Pre-sales Service

1. Inquiry and consulting support.

2. Sample testing support .

3. Recommend the mo

st suitable machine according to customer's purpose.

4. Factory

visiting welcomed.

After-sales Service

1. Training how to install the machine .

2. Training how to use the machine .

3. Warranty

1 year.

4. Engineers ava

ilable to service machinery oversea .

We use the wooden cabinet, protect the machine and can be e

asily

used forklift to unloading machine.

Our Factory

How about your mach

ine quality? We are

worry about the quality.

RE: Durmark company is a mature brand in CHINA,through our many years research in technology,our design including structure and detailed security and precision has enhanced greatly,and can match all the CE standard or more strict standard.Our machines distribute worldwide to about 50 countries where there are metal plate industry ,there are Brillante machines.And where there are our machines,there are good reputation and terminal user satisfaction.

Whether

the machine price can be more disc

ount?

RE:1. Durmark always provide high quality machine,as we know ,oversea market is more important and difficult than domestic market because of communication time costing after sales,So always,our machine has enough quality standard to make sure the machine can work more than the real warranty period.In this way ,we will save a lot and think in advance for the clients.

RE:2. we are sure to provide quality=price and price=quality ,the matched price and acceptable for the clients and durable for our machines.We welcome your negotiate with us and get a good satisfaction.

C onta ct