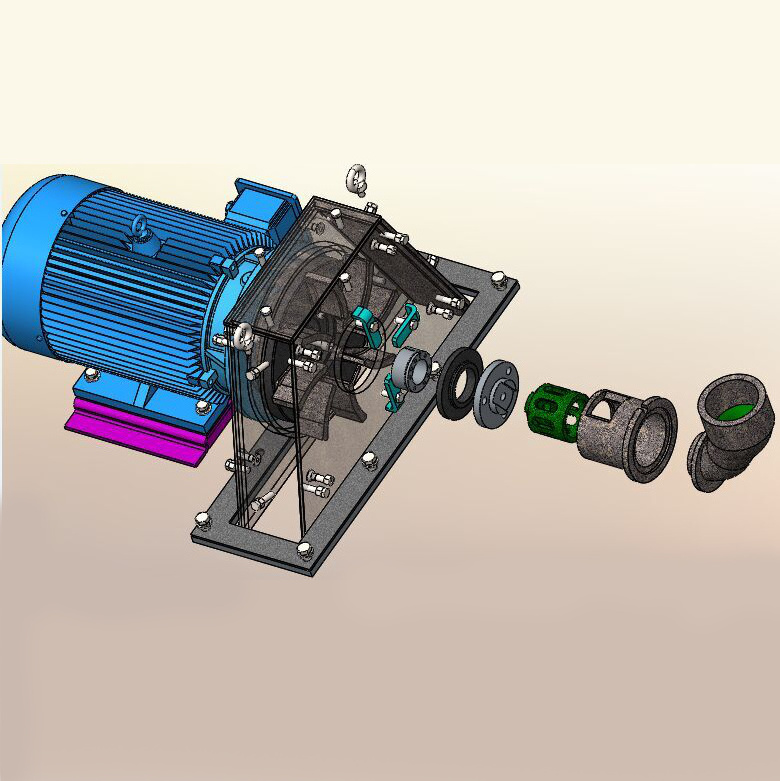

Impeller head is the key part of this machine, its working principle is: impeller creates centrifugal force and wind force during high speed rotating, pre-accelerate the shots when it flow into shot pipeline, under the action of centrifugal force, through orientation window and along vane length direction, speed up and blast at last. Formed shot sector stream attack work-piece surface.

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

140KW

-

Dimension(L*W*H):

-

Customized

-

Product name:

-

Steel Shot Blasting Machine

-

Application:

-

Large Metal Blasting

-

Type:

-

Shot Blasting Machine Equipment

-

Function:

-

Clean Workpiece

-

Color:

-

Blue

-

Shot blast machine type:

-

Work Pieces Flat

-

Blast wheel:

-

Driven Blast Wheel

-

Keywords:

-

Shot Machine

-

Export Countries:

-

20 Countries

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

WINCOO

-

Weight (KG):

-

200 KG

-

Power:

-

140KW

-

Dimension(L*W*H):

-

Customized

-

Product name:

-

Steel Shot Blasting Machine

-

Application:

-

Large Metal Blasting

-

Type:

-

Shot Blasting Machine Equipment

-

Function:

-

Clean Workpiece

-

Color:

-

Blue

-

Shot blast machine type:

-

Work Pieces Flat

-

Blast wheel:

-

Driven Blast Wheel

-

Keywords:

-

Shot Machine

-

Export Countries:

-

20 Countries

PRODUCT OVERVIEW

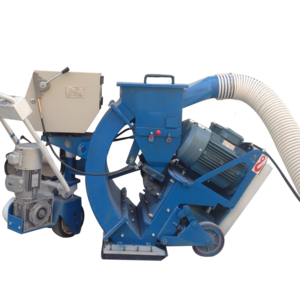

Shot-blasting machine

is a kind of shot-blasting equipment, which is applied to clean the surface of steel structure welding workpiece, H-style steel, plate and other profiles. It can clean away rusty spot, rusty scale, welding slag on the workpiece surface, as well as welding stress, in order to remove stress and improve surface lacquer quality and rot proofness of steel structure and steel.

TECHNICAL PARAMETER

|

Size of Workpiece

|

|

|

|

Width×height

|

≤800×1800mm

|

|

|

Length

|

3000-12000mm

|

|

|

Quality requirement

|

Sa2.5, Ra15-50

|

|

|

Impeller head

|

|

|

|

Model of impeller head

|

QZ320

|

|

|

Quantity of shot-blasting

|

8×200kg/min

|

|

|

Turning speed

|

2940r/min

|

|

|

Shot blasting speed

|

73m/s

|

|

|

Driving power

|

8×11KW

|

|

|

Workpiece conveying system

|

|

|

|

Length of input roller conveyor

|

12000mm

|

|

|

Length of output roller conveyor

|

12000mm

|

|

|

Length of roller conveyor in chamber

|

6100mm

|

|

|

Distance between roller conveyor out of chamber

|

1000mm

|

|

|

Load capacity of roller conveyor

|

1000kg/m

|

|

|

Conveying speed

|

0.5-5m/min

|

|

|

Shot conveying system

|

|

|

|

Capacity of shot conveying

|

120T/h

|

|

|

Longitudinal screw conveyor

|

|

|

|

Driving power

|

5.5KW

|

|

|

Power of bucket hoister

|

|

|

|

Driving power

|

7.5KW

|

|

|

Hoisting speed

|

1.5m/s

|

|

|

Hoisting capacity

|

120T/h

|

|

|

Power of curtain separator

|

|

|

|

Driving power

|

4KW

|

|

|

Width of curtain

|

2000mm

|

|

|

Steel shot diameter

|

ф0.8-ф1.2mm

|

|

|

Model of dusting system

|

|

|

|

Discharge quantity

|

<120mg/m3

|

|

|

Wind speed of the gate

|

<5m/s

|

|

|

Handling volume of dusting system

|

15000m3/h

|

|

|

Quantity of filter core

|

12

|

|

|

Filtering area (12×20)

|

240m2

|

|

|

Centrifugal ventilator Model

|

4-72-5A

|

|

|

Centrifugal ventilator air volume

|

15000m3/h

|

|

|

Centrifugal ventilator wind pressure

|

2022 Pa

|

|

|

Centrifugal ventilator power

|

15KW

|

|

|

Cleaning system ventilator power

|

15KW

|

|

|

Overall power

|

≈140KW

|

|

|

Whole machine air volume

|

15000m3/h

|

|

DETAILED DESCRIPTION

Compared with other machines,this machine has some advantages as following:

1,The quantity of shot-blasting and arrangement mode both are calculated by computer mass ejection simulation. The 8 impellers are located at upper and lower, right side and left side, ensuring that the bunch of projectiles ejected by shot-blasting cover the most part of the steel surface, including the end parts. It makes sure that the effect of shot-blasting is overall and effective.

2,The system is a centrifugal peering shot-blasting, which is adopted in advantages of massive shot-blasting and high ejection speed. Both the quantity and the momentum of the projectiles ejected to the workpiece surface are highly improved in unit time.So it can shorten the shot-blasting time, and improves the efficiency, comes to a pleasing cleaning quality.

3,Dedusting system adopts filtration type of back flushing. Dust collector adopts folded dedust filter cylinder, and the dedusting area has increased. The filter cylinder adopts nano-meter fiber technology; dust collection efficiency is more than 99.99%, especially for dust particles with a diameter of 0.5μm. After efficient filtration, the air is clean and can be recycle used or indoor emission. The pulse controller can adjust the frequency, speed and intensity of ash removal, compared with domestic traditional bag type single grade dedusting system, it has advantages of high dedust efficiency, lower operation resistance, small volume, light weight, easy replacement and so on. Emission quantity meets the national emission standard.

4,Shot sand separation system adopts advanced full curtain type, it’s invented by company after a long time research. It’s especially for steel structure shot separation cleaning after blasting. The performance i achieves home and abroad similar product level. The separation combines both wind selection and screening together, separates dust, metal oxide scale fragments,broken sand, large particles from qualified projectile, and obtains clean steel shot.

5,Spring steel plates and resistance rubber complex figure type baffles are installed in the two ends of shot-blasting chamber,in order to prevent projectiles splashing. At same time, it decreases the area of chamber in and out ports, so enhances the effect of dedust.

6,Projectile clean-away device is installed in every out port of chamber, it can blow away remained projectile on workpiece,reduce the wastage of projectile, lower the leakage of projectile. To the complicated structure workpiece, operator can clean projectile at outside. Dust is absorbed by dedusting system. This system adopts self-circulation type to clean the surface.

7,Adopting the international advanced technology projectile controller. Not only can control projectile self-support. But also can through the control valves’work schedule regulate projectile’s flow rate. So as to realize it supply controllable and adjustable. It can guarantee no leakage projectile and jam phenomenon .Diversion safe and reliable.

8,Aim at different specifications, shapes and complex degree of steel. The roller running speed can use transducer to on-line adjusting. Make different parts can get cleaning effect.

MAJOR COMPONENTS

The impeller head includes vane wheel, vane, shot dividing gear, orientation jacket and motor. Vane wheel is double disk structure. Vane adopts self position structure and is fastened in vane wheel depend on centrifugal force with features of convenient deinstallation and stable and reliable.

Vane, shot separating gear and orientation jacket use high chromium wearing alloy material, with characters of long lifetime. Vane can make sure for 1500 useful hours and shot separating gear 2000 hours and orientation jacket 2000 hours.

Turn orientation jacket can change shot blasting direction. And the adjusting principle is shot stream can cover work-piece completely.

CONSTRUCTION SITE PHOTOS

COMPANY PROFILE

Wincoo Engineering Co., Ltd (WINCOO) is engaged in bringing the most suitable solutions/equipments for client, fabricators, EPC/C companies on pipe fabrication, tank construction, pipeline construction,industrial production lines, clean energy project and other industrial field.

Our Services & Strength

We have ability of providing workable solutions to support clients to be awarded with shorter project execution time, fewer man-hour cost and higher efficiency construction/fabrication method and better quality during phase of project bidding.

Based client’s facility/site space availability, we are able to study/design and present matched configurations on project

schedule, quality, cost and productivity to guarantee production pace is accordance with project requirement.

To support project execution, we are always ready to work as fireman to give prompt supply on project materials from different consumables, tools, equipments/machines to special merchandise. With flexibility, we are also glad to perform as procurement agent in China to seek required supply resources.

Hot Searches