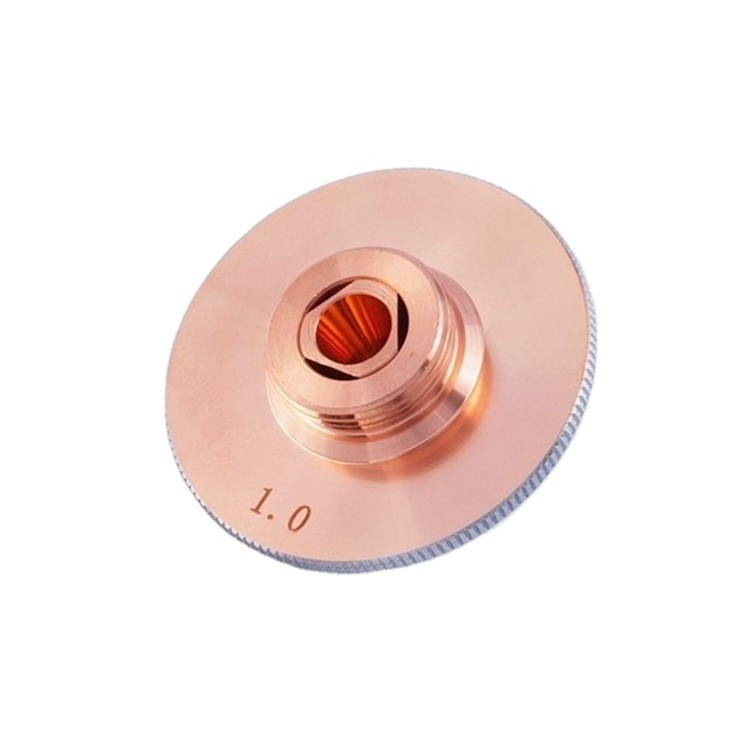

Why red copper precise nozzle is a better choice

1、 As one end of the electrode, the capacitance signal is collected. This is why we always emphasize that the laser nozzle must be made of red copper. It is because red copper has the best conductivity and certain strength in ordinary metals, and the heat dissipation effect is also good.

2、 The cavity inside the nozzle is used to form a gas field on the cutting surface to blow away the melt in the cutting process; In case of oxidative cutting, this gas field helps oxygen participate in metal oxidation (combustion) and speed up the cutting process. This is also the reason why we strictly control the finish of the inner cavity of the nozzle in the nozzle production process.

3、 Protect the interior of the laser cutting head, prevent the molten material from sputtering into the interior of the laser head, and reduce the pollution of foreign matters to the interior of the laser head. Considering the protective effect of the nozzle, we should avoid randomly removing the nozzle at the cutting site and minimize the exposure time of the interior of the laser head to the air.