- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

5.1*2.5*3.2m

-

Weight:

-

13tons biomass steam boiler

-

Boiler type:

-

1 Ton Industrial Wood Pellet Steam Coal Biomass Fired Steam Boiler

-

Boiler Working pressure:

-

12.5bar biomass steam boiler pellets

-

Thermal efficiency:

-

83%

-

Color for boiler:

-

Red or Customers'demands

-

Chain type of boiler:

-

manual stoker

-

Boiler barrel:

-

single barrel biomass steam boiler

-

OEM:

-

available for wood pellet boiler

-

Boiler Structure:

-

Three Passes Horizontal Fire Tube Biomass Boiler

-

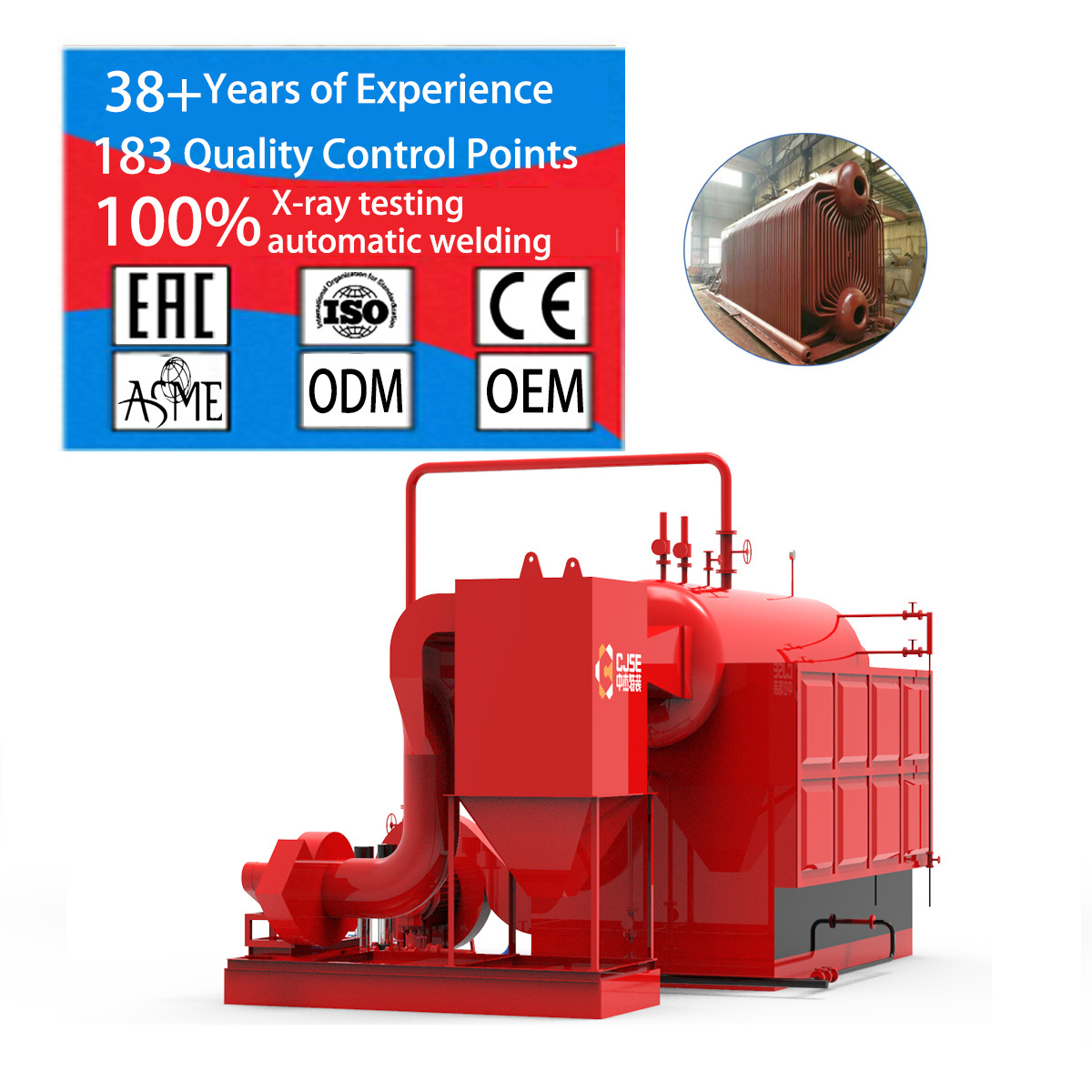

Certification:

-

ISO9001,ISO14001,ASME

Quick Details

-

Steam Production:

-

Max. 1t/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HEGUO/CJSE

-

Dimension(L*W*H):

-

5.1*2.5*3.2m

-

Weight:

-

13tons biomass steam boiler

-

Boiler type:

-

1 Ton Industrial Wood Pellet Steam Coal Biomass Fired Steam Boiler

-

Boiler Working pressure:

-

12.5bar biomass steam boiler pellets

-

Thermal efficiency:

-

83%

-

Color for boiler:

-

Red or Customers'demands

-

Chain type of boiler:

-

manual stoker

-

Boiler barrel:

-

single barrel biomass steam boiler

-

OEM:

-

available for wood pellet boiler

-

Boiler Structure:

-

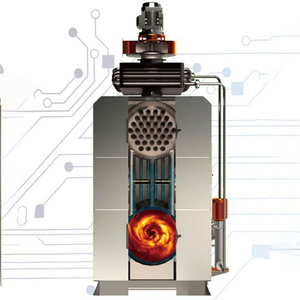

Three Passes Horizontal Fire Tube Biomass Boiler

-

Certification:

-

ISO9001,ISO14001,ASME

1 Ton Industrial Wood Pellet Steam Generator Coal Biomass Fired Steam Boiler

|

General introduction of Industrial Coal Wood Biomass Boiler 1. Steam Boiler capacity:1-4ton/h 2. Stem pressure: 0.7MPa (7bar) ,1.0MPa(10bar),1.25MPa(13bar), 1.6MPa(16bar) 3. Steam temperature output: 170℃, 184℃, 193℃, 204℃ 4. Available fuel: biomass, wood pellet,peanut, paddy, rice husk,sawdust solid fuel. 5. Boiler Structure: Horizontal three pass fire tube industrial used steam boiler 6. Application:used for all kinds of industrial production and processing. 7. Standard of Design, Manufacturing and Inspection: ASME / GB150 |

||||

|

Boiler Item |

Unit |

DZH2-1.0-SCI |

DZH1-1.25-SCI |

DZH4-1.25-SCI |

|

Rated steam output |

T/H |

2.0 |

1.0 |

4.0 |

|

Rated working pressure |

MPa |

1.0 |

1.25 |

1.25 |

|

Supply water temperature

|

℃ |

20 |

20 |

20 |

|

Rated steam temperature |

℃ |

184 |

193 |

193 |

|

Economizer heat transfer area |

M 2 |

51 |

51 |

78.8 |

|

Available Fuel |

|

Biomass Wood Coal Fuel |

||

|

Heat efficiency |

% |

84.59 |

81.54 |

80.83 |

|

Exhaust gas temperature |

℃ |

139.7 |

148.2 |

149.8 |

|

Transport dimension |

m |

5.05 x 2.5 x 3.2 |

5.05 x 2.25 x 3.05 |

5.5 x 2.8 x 3.4 |

|

Max. Part shipping weight |

T |

12.5 |

9.61 |

14.8 |

|

The way leaving the factory |

Quick Packaged |

Quick Packaged |

Quick Packaged |

|

Biomass Steam Boiler Main Features

1. Moving grate made of cast iron, large furnace design, manual stoker, good applicability of fuel, coal, wood, wood waste, biomass, etc. can be used as fuel.

2. Few moving parts, less investment, low operating costs, low maintenance costs.

3. Forced ventilation, pressure boost fast to make sure enough output.

4. Compact structure, easy to install, reducing the cost of the boiler room and installation cost.

5. Single drum design big water volume, ability to adapt to changes in load.

6. Sufficient combustion, large heating surface, adopt efficient threaded pipe, thermal efficiency higher than the national standard.

Advantages of Industrial Biomass Boiler Pellets

Compared with coal-fired boilers, biomass fuels are less expensive and significantly reduce operating costs. Our company can design the products with the best value for users by designing different requirements for users' different biomass fuels. Biomass boilers have the following advantages over other boilers:

1. Biomass boiler pellets can be used for cooking, boiling water and bathing while heating.

2. The boiler has a super-strong conversion system, low starting heat transfer temperature and fast heat transfer rate.

3. Biomass boiler pellets installation cost is low, equipment is common, does not change the original heating equipment, pipes, radiators are common, using water circulation to achieve heating.

4. The fuel source is extensive, never exhausted, and can be taken anywhere (eg: chaff, corn stalk, rice straw, wheat)

5. Industrial biomass boiler pellets is characteristic of s afety and environmental protection .

Our main products as below:

1)WNS/SZS Oil Gas Fired Steam Boiler/Hot Water Boiler;

2)DZH/DZL/SZL Model Biomass Pellet Wood/Coal Fired Steam Boiler / Hot Water Boiler;

3)YY(Q)W Series Natural Gas or Diesel Oil or Heavy Oil Fired Thermal Oil Boiler;

4)YGL/YGW/YLW Type Solid Fuel Wood Pellet Biomass Fired Thermal Oil Heater Boiler;

5)Waste Heat Recovery Boiler;

6) Stationary LPG Storage Tank (5000L to 200,000L)

7) Cryogenic Storage Tank (LNG Tank, Liquid Oxygen/Nitrogen/Argon/LCO2 Tank)

8) Mobile Skid Mounted LPG Filling Station (5000L to 60,000L)

9) Integrated design, manufacturing, and installation services