- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

-

-

CrO Content (%):

-

-

-

SiC Content (%):

-

≥88%

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

KRNC

-

Application:

-

Ceramic Kiln Furniture

-

Color:

-

Black

-

Usage:

-

Assemble and Install

-

Firing temperature:

-

1250~1320 ℃

-

Load - bearing:

-

200~300 Kg

-

Working temperature:

-

≤1380℃

-

Bulk density:

-

>3.02 g/cm3

-

AP:

-

<0.1 %

-

Thermal conductivity(1200℃):

-

45W/(m`K)

Quick Details

-

SiO2 Content (%):

-

-

-

Al2O3 Content (%):

-

1.5%

-

MgO Content (%):

-

-

-

CaO Content (%):

-

-

-

CrO Content (%):

-

-

-

SiC Content (%):

-

≥88%

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

KRNC

-

Application:

-

Ceramic Kiln Furniture

-

Color:

-

Black

-

Usage:

-

Assemble and Install

-

Firing temperature:

-

1250~1320 ℃

-

Load - bearing:

-

200~300 Kg

-

Working temperature:

-

≤1380℃

-

Bulk density:

-

>3.02 g/cm3

-

AP:

-

<0.1 %

-

Thermal conductivity(1200℃):

-

45W/(m`K)

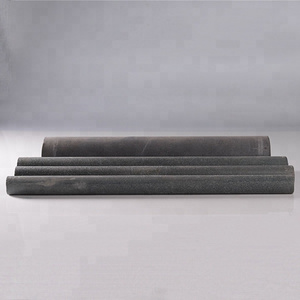

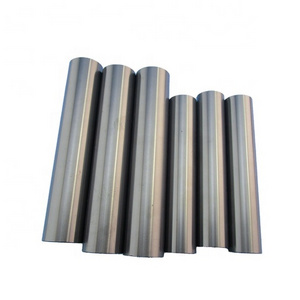

Reaction Sintered SiC Product Silicon Carbide Quantitative Tube/Pipe

Silicon carbide (SiC) support is a type of advanced ceramic material with excellent mechanical properties, high strength, and high temperature resistance. It is widely used in the semiconductor industry, as well as in various high-temperature applications such as ceramic processing, metallurgy, and high-temperature furnace construction.

Our silicon carbide support products are made from high-purity, fine-grained silicon carbide materials, which have excellent high-temperature stability and resistance to chemical corrosion. We offer a wide range of silicon carbide support products, including rods and tubes, which can be customized to meet the specific needs of our customers.

Our silicon carbide support products are designed to withstand high temperatures up to 1600°C (2912°F), making them ideal for use in high-temperature furnaces and kilns. They have a long service life and require minimal maintenance, which can help our customers reduce production costs and improve production efficiency.

In conclusion, our silicon carbide support products are an excellent choice for high-temperature applications in industries such as ceramics, metallurgy, and high-temperature furnace construction. We have a wide range of products to choose from, and we can customize the products to meet the specific needs of our customers. Our products are of high quality, have a long service life, and can help our customers reduce production costs and improve production efficiency.

|

Technical index |

Unit |

Parameter |

|

Recrystallized SiC content |

% |

> 99.5 |

|

Bulk density |

g/cm3 |

2.45-2.65 |

|

Apparent porosity |

% |

<11 |

|

Bending strength |

MPa |

>90-100 |

|

Compressive strength |

MPa |

>600 |

|

Thermal expansion (20-1100℃) |

10-6K-1 |

4.7 |

|

Thermal conductivity (500℃/h) |

W/m`K |

24 |

|

Young's modulus |

GPa |

240 |

|

Max working Temperature |

°C |

1650 |

|

Acid and alkali resistance |

|

Excellent |

|

Height(mm) |

Width(mm) |

Thickness(mm) |

Length(mm) |

|

20 |

20 |

4,5 |

800~1600 |

|

30 |

|||

|

25 |

25 |

||

|

30 |

30 |

5,6 |

800~2200 |

|

40 |

|||

|

50 |

|||

|

40 |

40 |

5,6,7 |

800~3600 |

|

50 |

|||

|

60 |

|||

|

50 |

50 |

800~3800 |

|

|

60 |

|||

|

70 |

|||

|

60 |

60 |

6,7,8,9 |

1000~4000 |

|

70 |

|||

|

80 |

|||

|

90 |

|||

|

70 |

70 |

7,8,9,10 |

|

|

80 |

|||

|

90 |