- Product Details

- {{item.text}}

Quick Details

-

Oiled or Non-oiled:

-

Non-oiled

-

Invoicing:

-

by theoretical weight

-

Place of Origin:

-

Shandong, China

-

Outer Diameter:

-

21.3 - 114.3 mm

-

Thickness:

-

2.8 - 4 mm

-

Grade:

-

q235, 10#-45#

-

Product name:

-

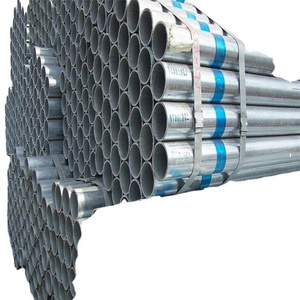

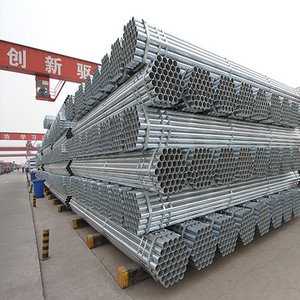

Hot Dip Galvanized Steel Pipe

-

Technology:

-

Hot Rolled Cold Rolled

-

Surface:

-

Galvanized Coated

-

Keyword:

-

Galvanzied Steel Pipe

-

MODEL:

-

Q195-Q345

-

Material:

-

16mn

-

Process:

-

Hanging plating

Quick Details

-

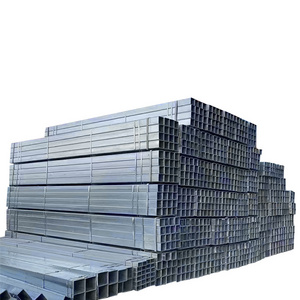

Section Shape:

-

Round

-

Surface Treatment:

-

galvanized

-

Tolerance:

-

±5%

-

Oiled or Non-oiled:

-

Non-oiled

-

Invoicing:

-

by theoretical weight

-

Place of Origin:

-

Shandong, China

-

Outer Diameter:

-

21.3 - 114.3 mm

-

Thickness:

-

2.8 - 4 mm

-

Grade:

-

q235, 10#-45#

-

Product name:

-

Hot Dip Galvanized Steel Pipe

-

Technology:

-

Hot Rolled Cold Rolled

-

Surface:

-

Galvanized Coated

-

Keyword:

-

Galvanzied Steel Pipe

-

MODEL:

-

Q195-Q345

-

Material:

-

16mn

-

Process:

-

Hanging plating

Product Description

Galvanized pipe, also known as galvanized steel pipe, is divided into hot-dip galvanizing and electro-galvanizing. The hot-dip galvanizing layer is thick, with uniform plating, strong adhesion and long service life. The cost of electroplating is low, the surface is not very smooth, and its corrosion resistance is much worse than that of hot-dip galvanized pipes.

Hot dip galvanized pipe

The molten metal is reacted with an iron matrix to produce an alloy layer, thereby combining the substrate and the plating layer. Hot-dip galvanizing is to pickle the steel pipe first, in order to remove the iron oxide on the surface of the steel pipe, after pickling, it is washed by ammonium chloride or zinc chloride aqueous solution or a mixed aqueous solution of ammonium chloride and zinc chloride, and then fed. Hot dip plating tank. Hot-dip galvanizing has the advantages of uniform plating, strong adhesion and long service life. Most of the northern processes use galvanized strips to directly coil the zinc.

Cold galvanized pipe

Cold galvanizing is electrogalvanizing. The amount of galvanizing is very small, only 10-50g/m2, and its corrosion resistance is much worse than that of hot-dip galvanized pipes. Regular galvanized pipe manufacturers, in order to ensure quality, most do not use electro-galvanizing (cold plating). Only small companies with small equipment and old equipment use electro-galvanized steel, of course, their prices are relatively cheaper. In newly built houses, the use of cold-galvanized steel pipes as water supply pipes is prohibited.

Hot dip galvanizing process:

Workpiece degreasing → washing → pickling → washing → drying solvent dip fluxing preheated hot dip galvanized → cooling → finishing → rinsing → drying → passivation test

Cold-galvanized process:

Chemical degreasing → washing → hot water hot water electrolysis degreasing → washing → washing → strong corrosive galvanized iron alloy → washing → washing → light → → washing → drying passivation

APPEARANCE OF HOT-DIP GALVANIZING AND COLD GALVANIZING

Cold galvanizing looks more smooth, bright, color passivation process plating layer is yellow-green in color, was colorful.

Plating layer was bluish-white or white with white passivation process was green, white coating passivation process and the sun was significant Colorful angle. The complex workpiece angular edges parts prone to "electrical burning" from gloomy, the parts of the zinc layer thick. Yin corner site is easy to form a current dead undercurrent gray area and the area zinc layer is thinner. The workpiece overall zinc tumor, caking phenomenon.

Hot dip galvanized look a little rough compared to the electro-galvanized, silvery white, look prone process waterlines and a few drops of tumor is more obvious, especially in the one end of the workpiece. Hot dip galvanized zinc layer than a few times of the electro-galvanized thick corrosion protection is several times that of the electro-galvanized.

The molten metal is reacted with an iron matrix to produce an alloy layer, thereby combining the substrate and the plating layer. Hot-dip galvanizing is to pickle the steel pipe first, in order to remove the iron oxide on the surface of the steel pipe, after pickling, it is washed by ammonium chloride or zinc chloride aqueous solution or a mixed aqueous solution of ammonium chloride and zinc chloride, and then fed. Hot dip plating tank. Hot-dip galvanizing has the advantages of uniform plating, strong adhesion and long service life. Most of the northern processes use galvanized strips to directly coil the zinc.

Cold galvanized pipe

Cold galvanizing is electrogalvanizing. The amount of galvanizing is very small, only 10-50g/m2, and its corrosion resistance is much worse than that of hot-dip galvanized pipes. Regular galvanized pipe manufacturers, in order to ensure quality, most do not use electro-galvanizing (cold plating). Only small companies with small equipment and old equipment use electro-galvanized steel, of course, their prices are relatively cheaper. In newly built houses, the use of cold-galvanized steel pipes as water supply pipes is prohibited.

Hot dip galvanizing process:

Workpiece degreasing → washing → pickling → washing → drying solvent dip fluxing preheated hot dip galvanized → cooling → finishing → rinsing → drying → passivation test

Cold-galvanized process:

Chemical degreasing → washing → hot water hot water electrolysis degreasing → washing → washing → strong corrosive galvanized iron alloy → washing → washing → light → → washing → drying passivation

APPEARANCE OF HOT-DIP GALVANIZING AND COLD GALVANIZING

Cold galvanizing looks more smooth, bright, color passivation process plating layer is yellow-green in color, was colorful.

Plating layer was bluish-white or white with white passivation process was green, white coating passivation process and the sun was significant Colorful angle. The complex workpiece angular edges parts prone to "electrical burning" from gloomy, the parts of the zinc layer thick. Yin corner site is easy to form a current dead undercurrent gray area and the area zinc layer is thinner. The workpiece overall zinc tumor, caking phenomenon.

Hot dip galvanized look a little rough compared to the electro-galvanized, silvery white, look prone process waterlines and a few drops of tumor is more obvious, especially in the one end of the workpiece. Hot dip galvanized zinc layer than a few times of the electro-galvanized thick corrosion protection is several times that of the electro-galvanized.

Specification

|

Product Name

|

Galvanized steel pipes

|

|

Standard

|

BS EN 10297, ASTM A312-2007, DIN 28180-2007, API 5DP, GB/T 14291-2006, JIS G3445-2006, ASTM A1020-2002

|

|

Grade

|

Q235, Q215, Q345, Q195, 16Mn, 10#, 20#, 45#

|

|

Thickness

|

0.2mm - 20mm

|

|

Section Shape

|

Round

|

|

Outer Diameter

|

10mm - 720mm

|

|

Place of Origin

|

China, Shandong

|

|

Application

|

Structure Pipe

|

|

Alloy Or Not

|

Non-alloy

|

|

Tolerance

|

±1%

|

|

Processing Service

|

Bending, WELDING, Decoiling, PUNCHING, Cutting

|

|

Application

|

building industry machinery/Construction of greenhouses.....

|

|

Regular Sizes of Galvanized Steel Pipe

|

|

|

|

|

||||

|

DN

|

NB

|

OD (mm)

|

WT (mm)

|

Pcs/Bundle

|

||||

|

15

|

1/2"

|

19mm-21.3mm

|

1.5mm-3.0mm

|

217

|

||||

|

20

|

3/4"

|

25mm-26.9mm

|

1.5mm-3.0mm

|

169

|

||||

|

25

|

1"

|

32mm-33.7mm

|

1.5mm-3.0mm

|

127

|

||||

|

32

|

1.1/4"

|

40mm-42.4mm

|

1.5mm-4.0mm

|

91

|

||||

|

40

|

1.1/2"

|

47mm-48.3mm

|

1.5mm-4.0mm

|

91

|

||||

|

50

|

2"

|

58mm-60.3mm

|

1.5mm-4.0mm

|

61

|

||||

|

65

|

2.1/2"

|

73mm-76.1mm

|

1.5mm-4.0mm

|

37

|

||||

|

80

|

3"

|

87mm-88.9mm

|

1.5mm-9.5mm

|

37

|

||||

|

100

|

4"

|

113mm-114.3mm

|

2.0mm-9.5mm

|

19

|

||||

|

125

|

5"

|

140mm-141.3mm

|

3.0mm-9.5mm

|

19

|

||||

|

150

|

6"

|

165mm-168.3mm

|

3.0mm-12.0mm

|

19

|

||||

|

200

|

8"

|

219.1

|

3.2mm-12.0mm

|

7

|

||||

|

250

|

10"

|

273.0

|

3.2mm-12.0mm

|

5 or 1

|

||||

|

300

|

12"

|

323.9mm-325mm

|

6.0mm-15mm

|

3 or 1

|

||||

|

350

|

14"

|

355mm-355.6mm

|

8.0mm-15mm

|

1

|

||||

|

400

|

16"

|

406.4mm

|

8.0mm-20mm

|

1

|

||||

|

450

|

18"

|

457mm

|

9.0mm-23mm

|

1

|

||||

|

500

|

20"

|

508mm

|

9.0mm-23mm

|

1

|

||||

|

550

|

22"

|

558.8mm

|

9.0mm-23mm

|

1

|

||||

|

600

|

24"

|

609.6mm

|

9.0mm-23mm

|

1

|

||||

|

Regular Length: 5.7m, 5.8m, 6.0m, 6.4m, 12m

Besides, we can make to order for you according to your requested length. |

|

|

|

|

||||

Application

Galvanized Steel Pipe is versatile and useful for a variety of applications. Some of the most common uses of carbon steel piping are:

Building foundations

Transporting natural gases or oil

Boiler and condenser tubes

Transporting wastewater

Chemical Processing

High-pressure applications

Transporting sewage

Bollard construction

Shipbuilding

Shoring

Trash enclosures

Distillers

OEM applications

Building foundations

Transporting natural gases or oil

Boiler and condenser tubes

Transporting wastewater

Chemical Processing

High-pressure applications

Transporting sewage

Bollard construction

Shipbuilding

Shoring

Trash enclosures

Distillers

OEM applications

Product Testing

Packing & Delivery

1.Bundled with narrow steel strips;

2.wrapped with waterproof colth;

3.Extra requires can be supported if customers need.

Hot Searches