This product combines cleaning welding and cutting functions into one, providing the market with a more efficient and flexible solution. It is a lightweight, protable, easy-to-operate, economical and intelligent innovative product.

- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Pratt cnc

-

Dimension(L*W*H):

-

760mmX780X790mm

-

Weight (KG):

-

60 KG

-

Product name:

-

Fiber Laser Cleaning Machine

-

Function:

-

Metal Rust Surface Laser Cleaning

-

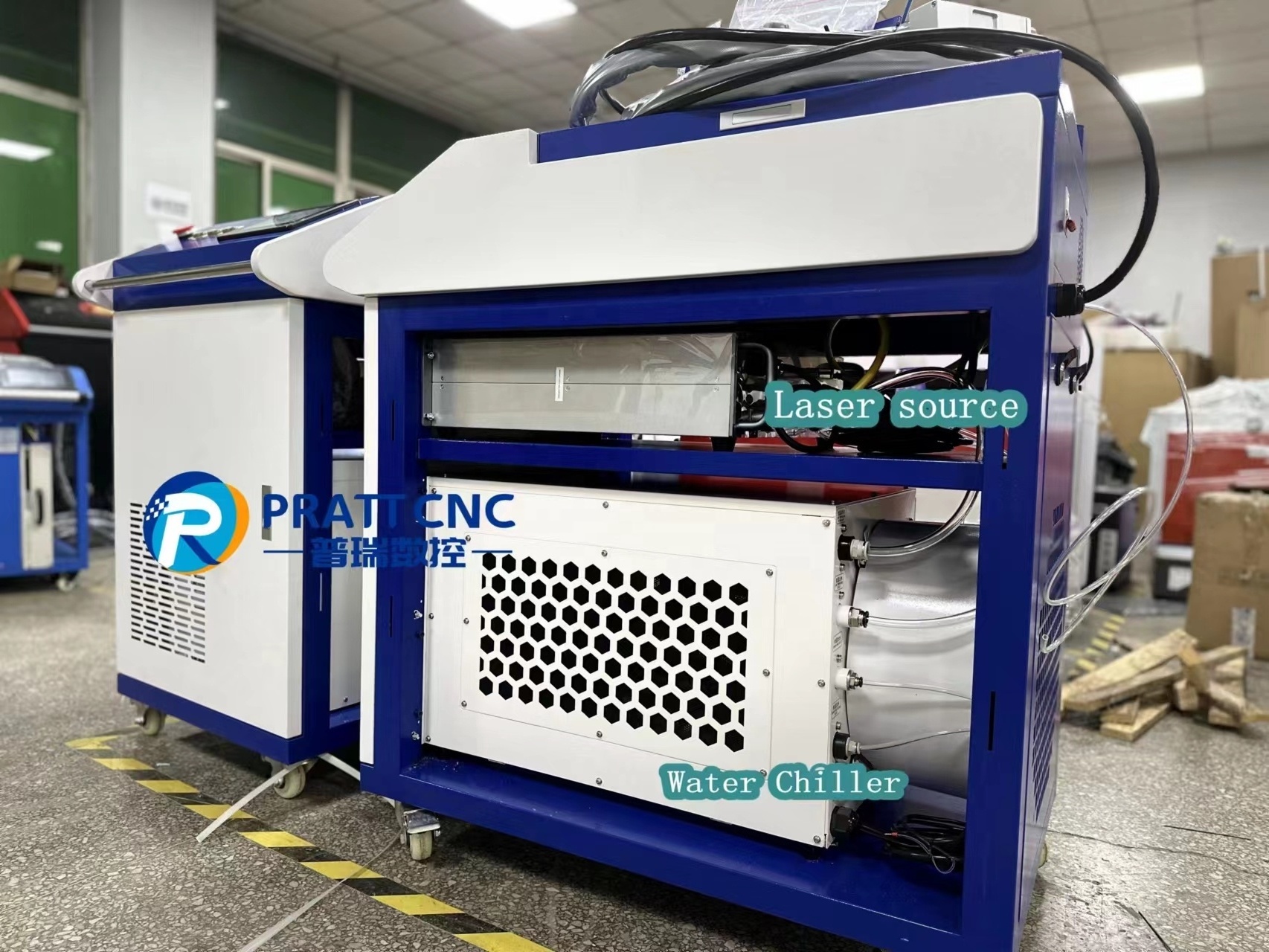

Laser source:

-

Raycus IPG MAX JPT

-

Power Supply:

-

1000W-3000W

-

Cleaning Width:

-

6-7cm

-

Cutting Depth:

-

0.1- 5 mm

-

Welding Depth:

-

0.1-6 mm

Quick Details

-

Power:

-

3000W, 1500W, 1000W, 2000W

-

Laser Type:

-

Fiber Laser

-

Laser Source Brand:

-

max /raycus /IPG

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Pratt cnc

-

Dimension(L*W*H):

-

760mmX780X790mm

-

Weight (KG):

-

60 KG

-

Product name:

-

Fiber Laser Cleaning Machine

-

Function:

-

Metal Rust Surface Laser Cleaning

-

Laser source:

-

Raycus IPG MAX JPT

-

Power Supply:

-

1000W-3000W

-

Cleaning Width:

-

6-7cm

-

Cutting Depth:

-

0.1- 5 mm

-

Welding Depth:

-

0.1-6 mm

Other products

Product Description

Multi-function Handheld Laser Cleaning/ Welding/ Cutting machine

Cleaning

1.Non-contact cleaning without damage to parts.

2.Precise cleaning, can achieve selective cleaning of precise position/precise size.

3.Simple operation, can be hand-held or with the machine to achieve automatic cleaning.

Welding

1.Fast welding speed, more than 5 times the speed of the traditional optical fiber transmission laser welding machine.

2.Large welding depth 0.1-6mm depends on different watts and firm welding at the same time.

3.With high precision it can fully meet the needs of users in different industries.

Cutting

1.Easy operation and fast cutting.

2.Maximum cutting depth 5mm.

Sample

Specification

|

Item

|

Value

|

|

Condition

|

New

|

|

Power

|

1500W, 1000W, 2000W, 3000w

|

|

Applicable Material

|

Stainless Steel, Carbon steel, Aluminum, Metal

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Marketing Type

|

New Product 2023

|

|

Warranty of core components

|

3 years

|

|

Core Components

|

Gear

|

|

Laser Type

|

Fiber Laser

|

|

Place of Origin

|

China

|

|

|

Shandong

|

|

Brand Name

|

Pratt cnc

|

|

Control System Brand

|

Laserfair cleaning system

|

|

Weight (KG)

|

60KG

|

|

Key Selling Points

|

Easy to Operate

|

|

Warranty

|

2 years

|

|

Applicable Industries

|

Printing Shops, Manufacturing Plant, Home Use, Construction works , Machinery Repair Shops, Energy & Mining, Other

|

|

Product name

|

Fiber Laser Cleaning Welding Cutting Machine

|

|

Function

|

Metal Rust Surface Laser Cleaning/ Metal Laser welding /Metal Laser Cutting

|

|

Laser source

|

Raycus IPG MAX JPT

|

|

Power Supply

|

1000W-3000W

|

Our Advantages

Environmental protection advantages

:

Laser cleaning is a "green" cleaning method, without the use of any chemicals or cleaning

fluids. The cleaned waste is basically solid powder, small in size, easy to store, recyclable, no photochemical reaction, no Will

cause pollution. Can easily solve the environmental pollution problems caused by chemical cleaning. Often a single exhaust fan can

solve the problem of waste generated by cleaning.

Effect advantages: The traditional cleaning method is often contact cleaning, which has mechanical force on the surface of the

cleaning object, the surface of the damaged object or the cleaning medium is attached to the surface of the object to be cleaned,

and cannot be removed, resulting in secondary pollution. Grinding and non-contact, no thermal effects will not damage the

substrate, making these problems solved.

Convenient advantage: laser cleaning can remove various types of contaminants on the surface of various materials, reaching a

degree of cleanliness that cannot be achieved by conventional cleaning. It can also selectively clean contaminants on the surface

of the material without damaging the surface of the material.

Cost advantage: laser cleaning speed is fast, high efficiency, save time; although the initial investment of the laser cleaning

system is high, the cleaning system can be used for a long time and stable, the operating cost is low, and more importantly, it

can be easily automated. Cost calculation: single cleaning efficiency of 8 square meters per hour per hour operating cost is about

5 kWh electricity cost, that is, the cleaning cost is 4 cents per square meter, except for the initial cost, the latter 4 cents

per square meter.

Control advantages: The laser can be transmitted through the optical fiber, cooperate with the robot hand and the robot,

conveniently realize long-distance operation, and can clean the parts that are difficult to reach by traditional methods, which

can ensure the safety of personnel when used in some dangerous places

fluids. The cleaned waste is basically solid powder, small in size, easy to store, recyclable, no photochemical reaction, no Will

cause pollution. Can easily solve the environmental pollution problems caused by chemical cleaning. Often a single exhaust fan can

solve the problem of waste generated by cleaning.

Effect advantages: The traditional cleaning method is often contact cleaning, which has mechanical force on the surface of the

cleaning object, the surface of the damaged object or the cleaning medium is attached to the surface of the object to be cleaned,

and cannot be removed, resulting in secondary pollution. Grinding and non-contact, no thermal effects will not damage the

substrate, making these problems solved.

Convenient advantage: laser cleaning can remove various types of contaminants on the surface of various materials, reaching a

degree of cleanliness that cannot be achieved by conventional cleaning. It can also selectively clean contaminants on the surface

of the material without damaging the surface of the material.

Cost advantage: laser cleaning speed is fast, high efficiency, save time; although the initial investment of the laser cleaning

system is high, the cleaning system can be used for a long time and stable, the operating cost is low, and more importantly, it

can be easily automated. Cost calculation: single cleaning efficiency of 8 square meters per hour per hour operating cost is about

5 kWh electricity cost, that is, the cleaning cost is 4 cents per square meter, except for the initial cost, the latter 4 cents

per square meter.

Control advantages: The laser can be transmitted through the optical fiber, cooperate with the robot hand and the robot,

conveniently realize long-distance operation, and can clean the parts that are difficult to reach by traditional methods, which

can ensure the safety of personnel when used in some dangerous places

Hot Searches