- Product Details

- {{item.text}}

Quick Details

-

Output Speed:

-

300rpm to 0.0000012rpm

-

Place of Origin:

-

Taiwan, China

-

Input pole:

-

2P , 4P , 6P , 8P

-

Speed Reducer type:

-

Cyclo Drive Gear

-

Production Standard:

-

ISO , JIS , DIN , CNS , CE , ROHS

-

Efficiency:

-

95% on single Stages

-

Interchange with:

-

Sumitomo

-

Product name:

-

servo motor planetary gearbox

-

Ratio:

-

1/6 to 1/57289761

-

Certification:

-

ISO9001

-

Material:

-

Gear: Bearing Steel

-

Cyclo Drive Type:

-

6000 Series

Quick Details

-

Gearing Arrangement:

-

Cycloidal

-

Output Torque:

-

7.5 nM & above

-

Input Speed:

-

1800 @ 60Hz , 1500 @ 50hz

-

Output Speed:

-

300rpm to 0.0000012rpm

-

Place of Origin:

-

Taiwan, China

-

Input pole:

-

2P , 4P , 6P , 8P

-

Speed Reducer type:

-

Cyclo Drive Gear

-

Production Standard:

-

ISO , JIS , DIN , CNS , CE , ROHS

-

Efficiency:

-

95% on single Stages

-

Interchange with:

-

Sumitomo

-

Product name:

-

servo motor planetary gearbox

-

Ratio:

-

1/6 to 1/57289761

-

Certification:

-

ISO9001

-

Material:

-

Gear: Bearing Steel

-

Cyclo Drive Type:

-

6000 Series

<< More Information is Available upon Request >>

Quality Gear box by Vari tron from TAIWAN

Varitron Cyclo Drive Gear box Speed Reducer servo motor planetary gearbox

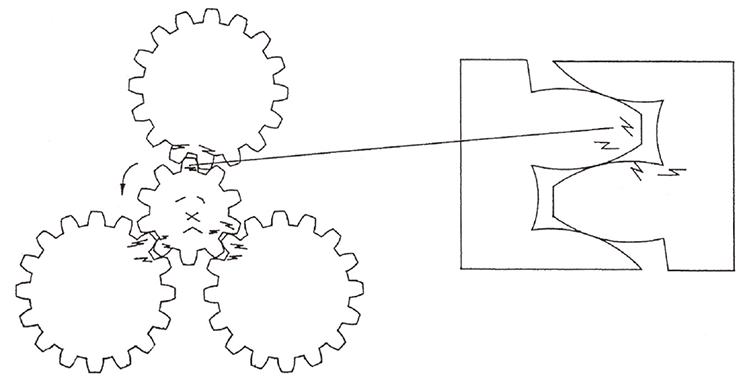

The VARITRON Cycloidal Drive unique cycloid gear design has advantages superior to common involute tooth gears system speed reducers.

VARITRON's Cycloidal Drive matchless performance and reliability is that 67% of the reduction components are in contact at all times, compared to helical gear and planetary gear designs that use only limited tooth contact. Unlike geared designs, the Varitron's reduction components operate in compression rather than shear, which results to withstand shock loads exceeding ratings of 500%, provide exceptional performance, reliability and long life in most severe applications.

Main Features

- Involute gear has slip contact with less contact ratio

- Varitron cycloidal drive has smooth rolling contact

- Durable and Long Service Life

The gear tooth profile of the VARITRON Cycloidal Drive enables the sharing of the load by a number of teeth, thus not susceptible to tooth breakage. At least 66% of ring gear rollers and cycloid disc loves share the shock load under compression. In addition, major torque transmission components inside the VARITRON Cycloidal Drive are made of 52100(JIS SUJ2) high carbon chromium bearing grade steel hardened to Rockwell Hardness of HRC 61~63 andwith precision grinding. The end result is that VARITRON Cycloidal Drive are capable of withstanding intermittent shock load up to 500% of its catalog torque rating.

- High Efficiency

Rolling Contact-All major torque transmitting components roll; they do not slide. Rolling motion contributs to minimal frication and high efficiency approaches 93%, anddouble stage efficiency approaches 93%, and double stage efficiency approaches 86%.

- Simple Maintenance

Lifetime grease lubrication or easy-to-replenish oil lubrication.

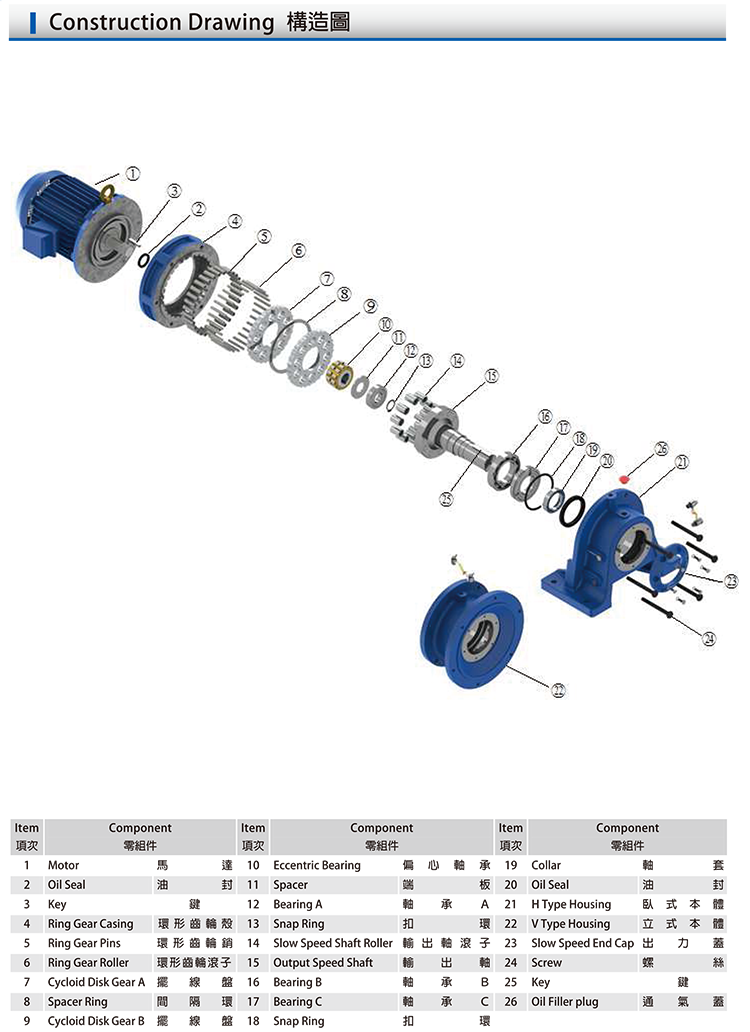

- Housing

Standard gray cast iron(JIS FC25) iron provides rigid structural integrity. Optional ductile iron housing(JIS FCD45) available.

- Output Shaft

High Strength Low Alloy Stell(JIS SCM21) with oversized bearings for excellent overhung load capacit and outstanding performanc.

- Dual Lips Oil Seal

Keeps lubricant in; keeps dirt out. (for flange model 8165 and above double dual lips oil seal on output side)

- Side Window (Oil Lubricate Models)

For easy oil level and clarity reading. Installing side can assign on ordering. Markers also on the side window to show how mcuk oil to fill.

- BREATHER FILLER CAP

Large oil filler hole. Oil cap also functions for pressure release purpose.

- Drain Plugs (Oil Lubricated Models)

Magnetic drain plugs design to prevent any steel dust from bearingor gear when wear in the oil. Drain plugs on double side for simple oil replavement.

Cycloidal Drive Construction Drawing

Cycloidal Drive Model

Cycloidal Drive Operation Direction

Quick Facts

| Model Number | Varitron Cyclo Drive Gear box Speed Reducer servo motor planetary gearbox |

| Speed Reduction Method | Internal planetary gear mechanism with trochoidal curved tooth profile design speed reduction |

| Efficiency | 95% per stage gear box (Rolling motion minimizes friction and wear, reducing heat) |

| Shock Load | 500% as there are only compressive forces rather than shear forces on the tooth |

| Gear Box Mounting | Flange or Foot mounting |

|

Gear Reduction Ratio |

Up to 1:87 per stage 1:7569 Double stage 1:658,503 Triple Stage |

| Capacity Range | 0.1 to 75kW * 4Pole / 0.37 to 132kW * 6Pole |

| Enclosure | Totally enclosed fan cooled type IP54 or IP55 |

| Power Source | Three Phrase 200-480V 50/60Hz (single phrase 0.2 to 3.7kW) |

| Thermal Class | F Class , H Class |

| Time Rating | Continuous Rating |

|

Gear Box Lubrication Method |

Grease lubricated or Oil Lubricated (oil Pump lubrication avaliable) |

| Method of Coupling with Driven Machine | Coupling, gears, chain sprocket or belt |

| Standard | CE, UL, CSA, CCC, ISO 9001, ISO 14001 |

| Warranty | 1 Year Limited Warranty |

Cycloidal Drive How to order

<< More Detailed Information You May Needed >>

Applications

Agitators Mixers,

Brewing and Distilling,

Conveyors,

Extruders,

Food industry,

Metal Mills,

Hammer mills,

Paper Mills,

Lumber Industry,

Rubber & Plastics Industries,

Sewage Disposal Equipment,

Oil Industry,

Textile Industry,

Sugar Industry,

Dry Dock Cranes.. and many more

Gearbox will be delievery with crate or wooden box.

Take Control In Speed