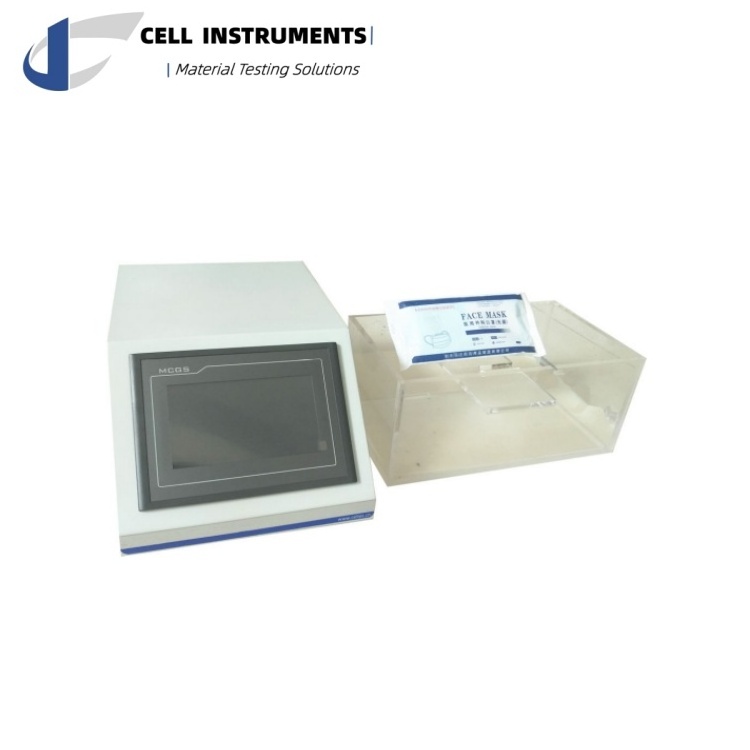

Gross Leak Tester is a destructive test method for detecting gross leaks in packaging by internal pressurization. This is also called the bubble test, submersion test, underwater immersion tester and dunking test, etc., and is primarily used for pouch, sterile packaging, etc.

ASTM F2096 describes a procedure to detect gross leaks from porous and non-permeable packaging materials through the use of internal pressurization bubble test.