- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Provided

-

Type:

-

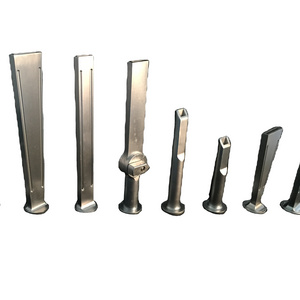

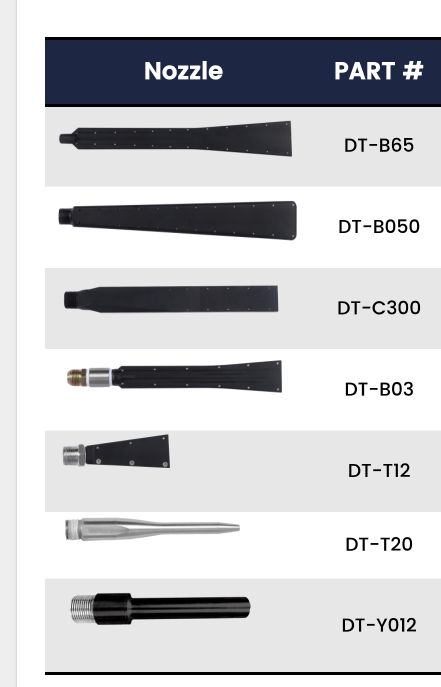

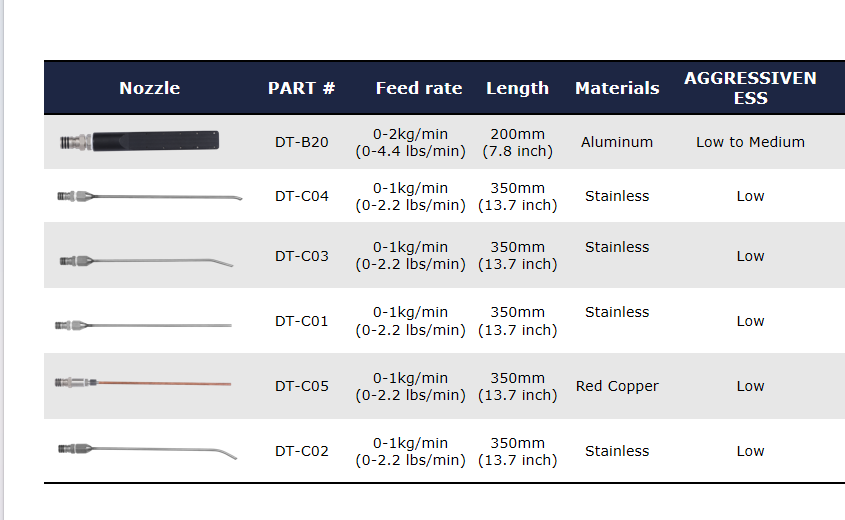

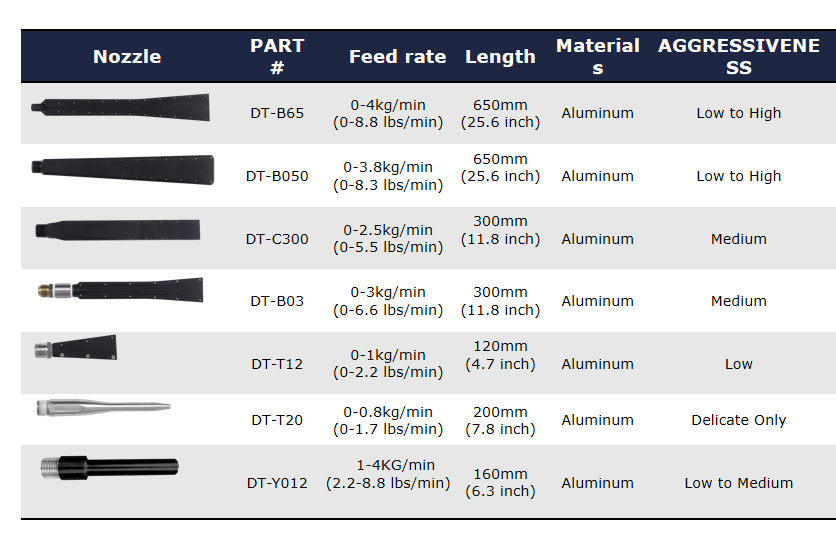

Dry ice blasting machine, Nozzle

-

Product name:

-

Dry ice blasting flat compressed air nozzle

-

Material:

-

ABS / AL / PP / PVC / SS

-

Spray pattern:

-

Flat Blow

-

Usage:

-

Cleaning

-

Size:

-

Custom

Quick Details

-

Applicable Industries:

-

Dry ice blasting machine

-

Weight (KG):

-

1

-

Place of Origin:

-

China

-

Brand Name:

-

Provided

-

Type:

-

Dry ice blasting machine, Nozzle

-

Product name:

-

Dry ice blasting flat compressed air nozzle

-

Material:

-

ABS / AL / PP / PVC / SS

-

Spray pattern:

-

Flat Blow

-

Usage:

-

Cleaning

-

Size:

-

Custom

Technical Parameters

|

Name

|

Dry ice blasting flat compressed air nozzle

|

|

Size

|

Custom

|

|

Inlet Dia

|

1/4",3/8",1/2",3/4"

|

|

Material

|

ABS / AL / PP / PVC / SS

|

|

Application

|

Dust Control

|

|

Weight

|

0.5kg-1kg

|

|

Usage

|

Cleaning,Cooling

|

Products Description

Types:SS adjustable ball adapter, PP adjustable ball adapter, Hose clamps

Material: BS / AL / PP / PVC / SS

Set for all air nozzles.

Material: BS / AL / PP / PVC / SS

Set for all air nozzles.

Recommend Products

Certifications

Customer Feedback

Steven K., Auto Repair Shop Owner:

"I've been searching for a high-yield, easy-to-operate dry ice production machine, and DRYICEJET Dry Ice Machine exceeded my expectations. Its high productivity and versatility allow me to provide excellent service to my customers, and its reliability is impressive."

Linda T., Restaurant Industry Manager:

"As a food industry manager, I've been looking for a reliable refrigeration solution. The multi-application feature of the

DRYICEJET Dry Ice Machine makes it our top choice. The size of dry ice pellets it produces is perfect for our refrigeration needs."

DRYICEJET Dry Ice Machine makes it our top choice. The size of dry ice pellets it produces is perfect for our refrigeration needs."

John M., Pharmaceutical Production Supervisor

"We needed an efficient dry ice production machine to meet cleaning requirements in pharmaceutical manufacturing. The

DRYICEJET

Dry Ice Machine delivers outstanding performance, helping us maintain high cleaning and hygiene standards."

About Us

Packaging&Shipping

FAQ

Q1:

How is dry ice made?

Dry ice is the solid form of carbon dioxide (CO2). In order to create dry ice, CO2 is first captured at an industrial or biogas

facility. That CO2 is recycled via a process that pressurizes the gas and cools it to form liquid CO2 (LCO2). Once the LCO2 is onsite at the production point, it is then injected into a pelletizer, or dry ice production unit. Within the pelletizer, the

pressurized LCO2 is released to atmospheric pressure, which causes it to solidify into a snow-like consistency. This is then

compressed into pellets, blocks, or slabs. Q2. Can I make my own dry ice?

Dry ice can be produced on demand using a dry ice production machine (pelletizer or slice maker). Producing your own dry ice must be economically viable and the amount of dry ice used on a daily and weekly basis must be considered.

Pelletizers, slice makers, and reformers can be equipped with multiple dies to produce a range of extrusion sizes (3mm to 19mm) and final product size. Dry ice production equipment can produce, dose, and package multiple sizes of dry ice for a broad range of solutions. Q3. Should I make my own dry ice?

In the right situation, making your own dry ice can save you a lot of time and money while eliminating headaches. Producing your own dry ice can give you greater control over your production, processing, and cold chain management systems, while also reducing waste and cutting operational costs.

By answering a few simple questions, you can determine whether producing your own dry ice is right for you. Those questions include:

1. How much dry ice do you consume weekly/monthly?

2. What are your current delivery costs?

3. Is dry ice a part of a critical path in your operation?

4. Do you waste a lot of dry ice per week?

5. Does your facility have a CO2 tank and three-phase power? Q4: What types of infrastructure do I need for a dry ice production machine?

You need a liquid CO2 tank, three phase power, exhaust capability, supply and support lines, and adequate floor space for both the dry ice production machine and dry ice storage.

If you do not have a liquid CO2 supply already in place, Cold Jet can perform a site visit to help determine what you would need to do and what your investment and payback would be. Cold Jet can then arrange for the installation and leasing, if required, to be completed through our trusted affiliates. Q5: How much LCO2 do I need to produce a pound of dry ice?

DRYICEJET’s conversion rate is as low as 2.2 to 1 of LCO2 to solid dry ice. Most of our competitors remain at a 2.7 conversation ratio or above. Q6: How do I store dry ice and how long does it last?

Dry ice should be stored in an insulated container. The thicker the insulation, the slower it will sublimate. Depending on the

climate and thickness of your container, typical dry ice sublimation is approximately 2% to 10% per day.

Dry ice is the solid form of carbon dioxide (CO2). In order to create dry ice, CO2 is first captured at an industrial or biogas

facility. That CO2 is recycled via a process that pressurizes the gas and cools it to form liquid CO2 (LCO2). Once the LCO2 is onsite at the production point, it is then injected into a pelletizer, or dry ice production unit. Within the pelletizer, the

pressurized LCO2 is released to atmospheric pressure, which causes it to solidify into a snow-like consistency. This is then

compressed into pellets, blocks, or slabs. Q2. Can I make my own dry ice?

Dry ice can be produced on demand using a dry ice production machine (pelletizer or slice maker). Producing your own dry ice must be economically viable and the amount of dry ice used on a daily and weekly basis must be considered.

Pelletizers, slice makers, and reformers can be equipped with multiple dies to produce a range of extrusion sizes (3mm to 19mm) and final product size. Dry ice production equipment can produce, dose, and package multiple sizes of dry ice for a broad range of solutions. Q3. Should I make my own dry ice?

In the right situation, making your own dry ice can save you a lot of time and money while eliminating headaches. Producing your own dry ice can give you greater control over your production, processing, and cold chain management systems, while also reducing waste and cutting operational costs.

By answering a few simple questions, you can determine whether producing your own dry ice is right for you. Those questions include:

1. How much dry ice do you consume weekly/monthly?

2. What are your current delivery costs?

3. Is dry ice a part of a critical path in your operation?

4. Do you waste a lot of dry ice per week?

5. Does your facility have a CO2 tank and three-phase power? Q4: What types of infrastructure do I need for a dry ice production machine?

You need a liquid CO2 tank, three phase power, exhaust capability, supply and support lines, and adequate floor space for both the dry ice production machine and dry ice storage.

If you do not have a liquid CO2 supply already in place, Cold Jet can perform a site visit to help determine what you would need to do and what your investment and payback would be. Cold Jet can then arrange for the installation and leasing, if required, to be completed through our trusted affiliates. Q5: How much LCO2 do I need to produce a pound of dry ice?

DRYICEJET’s conversion rate is as low as 2.2 to 1 of LCO2 to solid dry ice. Most of our competitors remain at a 2.7 conversation ratio or above. Q6: How do I store dry ice and how long does it last?

Dry ice should be stored in an insulated container. The thicker the insulation, the slower it will sublimate. Depending on the

climate and thickness of your container, typical dry ice sublimation is approximately 2% to 10% per day.

Q7:

How much does a dry ice production machine cost?

We have a number of different machine options depending on your production needs.

Contact a Cold Jet representative to find out what the best machine will be for you. Q8: Are there safety precautions with dry ice production?

When working with CO2, precaution must always be taken to ensure that the area is sufficiently ventilated and that proper PPE is administered when dealing with the liquid or solid form of CO2 (dry ice). Q9: Is dry ice environmentally sustainable?

Dry ice is the most environmentally sustainable and effective cooling medium used in keeping temperature sensitive products cold.

1. Dry ice is made of recycled CO2

Dry ice is the product of a carbon capture and utilization (CCU) process. CO2 is captured at industrial and biogas facilities, recycled, and converted to dry ice. The CO2 would have otherwise been discarded as waste is given a second life as a cooling and cleaning medium. The dry ice does not add to emissions or produce more CO2.

2. Eliminate Additional Emissions

Refrigerated vehicles use up to 15% more fuel than standard delivery vehicles and release 18% more nitrogen oxide emissions.

3. Replace Traditional Cooling Methods

Dry ice allows companies to replace resource intensive and waste generating gel packs with an environmentally sustainable cooling medium.

4. Increased Fuel Efficiency For Shipping

Dry ice sublimates throughout transit and continually loses weight, which helps logistics companies experience greater fuel efficiencies.

We have a number of different machine options depending on your production needs.

Contact a Cold Jet representative to find out what the best machine will be for you. Q8: Are there safety precautions with dry ice production?

When working with CO2, precaution must always be taken to ensure that the area is sufficiently ventilated and that proper PPE is administered when dealing with the liquid or solid form of CO2 (dry ice). Q9: Is dry ice environmentally sustainable?

Dry ice is the most environmentally sustainable and effective cooling medium used in keeping temperature sensitive products cold.

1. Dry ice is made of recycled CO2

Dry ice is the product of a carbon capture and utilization (CCU) process. CO2 is captured at industrial and biogas facilities, recycled, and converted to dry ice. The CO2 would have otherwise been discarded as waste is given a second life as a cooling and cleaning medium. The dry ice does not add to emissions or produce more CO2.

2. Eliminate Additional Emissions

Refrigerated vehicles use up to 15% more fuel than standard delivery vehicles and release 18% more nitrogen oxide emissions.

3. Replace Traditional Cooling Methods

Dry ice allows companies to replace resource intensive and waste generating gel packs with an environmentally sustainable cooling medium.

4. Increased Fuel Efficiency For Shipping

Dry ice sublimates throughout transit and continually loses weight, which helps logistics companies experience greater fuel efficiencies.

Contact US

Hot Searches