- Product Details

- {{item.text}}

Quick Details

-

Output (kg/h):

-

350 - 400 kg/h

-

Transformer capacity:

-

250KVA

-

Labor:

-

2-3 persons

-

Motor:

-

Siemens

-

Inverter:

-

ABB

-

Temperature controller:

-

Omron Japan

-

Switch:

-

Schneider

-

Contactor:

-

Schnerder

-

Hscode:

-

8477209000

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

22:1

-

Place of Origin:

-

China

-

Output (kg/h):

-

350 - 400 kg/h

-

Transformer capacity:

-

250KVA

-

Labor:

-

2-3 persons

-

Motor:

-

Siemens

-

Inverter:

-

ABB

-

Temperature controller:

-

Omron Japan

-

Switch:

-

Schneider

-

Contactor:

-

Schnerder

-

Hscode:

-

8477209000

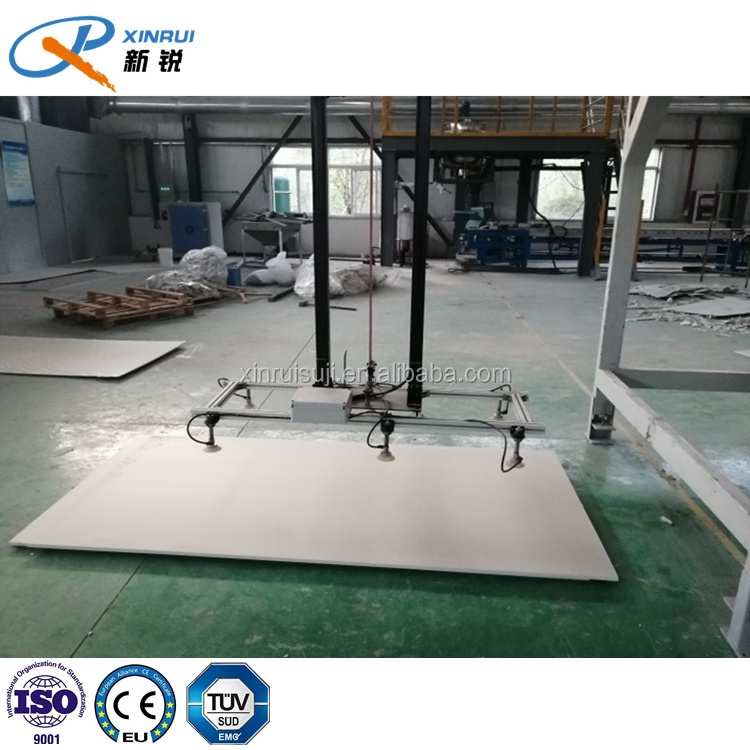

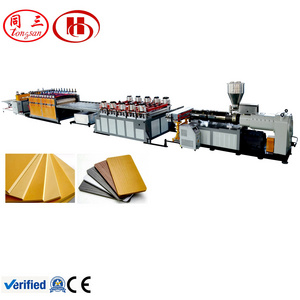

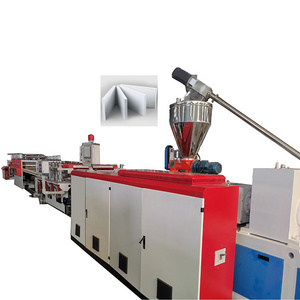

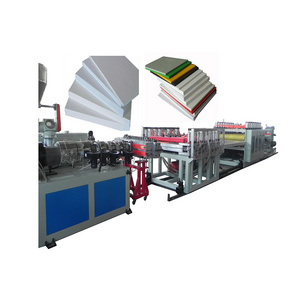

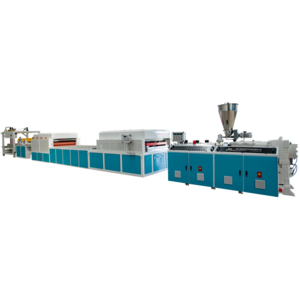

PVC Foam Board Machine:

MAIN PARAMETERS OF PVC FOAM BOARD:

Width: 1220mm

Length: 2440mm

Thickness: 3-40mm

Density: 0.38-0.8g/cm3

Output: 350-400kg/h or 550-600kg/h or 700kg/h, it depends on the choice of extruder.

ENVIRONMENTAL CONDITION:

| Location | Indoors |

| Power Supply | No dangerous area |

| Humidity | ≤95% |

| Temperature | 0-40ºC |

| Power | 3-phase, 380V, 50Hz |

| Total Installed Power | <300KW |

| Cooling Water | ≤25ºC ≥0.3MPa, outdoor water tank: 20-30m3, water circulated with production line |

| Compressed air |

0.3 m³ /min, >0.5MPa,

Equipped with 5.5-7.5kw air compressor |

| Production Line Dimension | 25m*3m*3m |

Flow chart:

Mixer→Loader→Extruder→Mould→Calibration platform→Cooling bracket→Hauling machine→Cutting machine(With dust collector)→Stacker

→Packing→Crusher(for waste material) →Pulverizer(For recycled material)