Original: Guangdong,China (mainland)

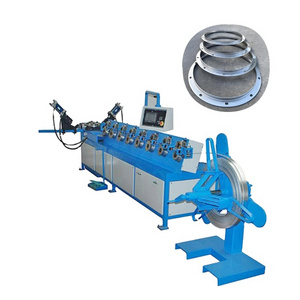

①

Max.

width: 200mm

②

Inner Diameter

:

Ø

460mm-520mm

③

Max.

outside diameter:

Ø

1300mm

④

Max. Loading Capacity

: 1Ton

⑤ Adopts manual core expansion

⑥No power transmission, with brake

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.8-1.0mm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Liding

-

Voltage:

-

380V 50Hz 3Phases

-

Dimension(L*W*H):

-

7000*800*1200mm

-

Weight:

-

2500 kg

-

Feeding width:

-

Customized

-

Product name:

-

tdc flange forming machine

-

Keywords:

-

roll forming Making Machine

-

Selling point:

-

High-accuracy

-

Cutting blade material:

-

cr12 with quenched treatment

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Operation:

-

Automatic

-

Electric Control system:

-

Fully Automatic PLC(imported Brand),transducer, touch panel

-

Material:

-

PPGI PPGL GI GL

-

Profile design:

-

custom

-

motor brand:

-

China Famous Brand

Quick Details

-

Type:

-

Other Roll Forming Machine

-

Tile Type:

-

Galvanised steel coils

-

Production Capacity:

-

6-8M/Min

-

Rolling thinckness:

-

0.8-1.0mm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Liding

-

Voltage:

-

380V 50Hz 3Phases

-

Dimension(L*W*H):

-

7000*800*1200mm

-

Weight:

-

2500 kg

-

Feeding width:

-

Customized

-

Product name:

-

tdc flange forming machine

-

Keywords:

-

roll forming Making Machine

-

Selling point:

-

High-accuracy

-

Cutting blade material:

-

cr12 with quenched treatment

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Operation:

-

Automatic

-

Electric Control system:

-

Fully Automatic PLC(imported Brand),transducer, touch panel

-

Material:

-

PPGI PPGL GI GL

-

Profile design:

-

custom

-

motor brand:

-

China Famous Brand

Products Description

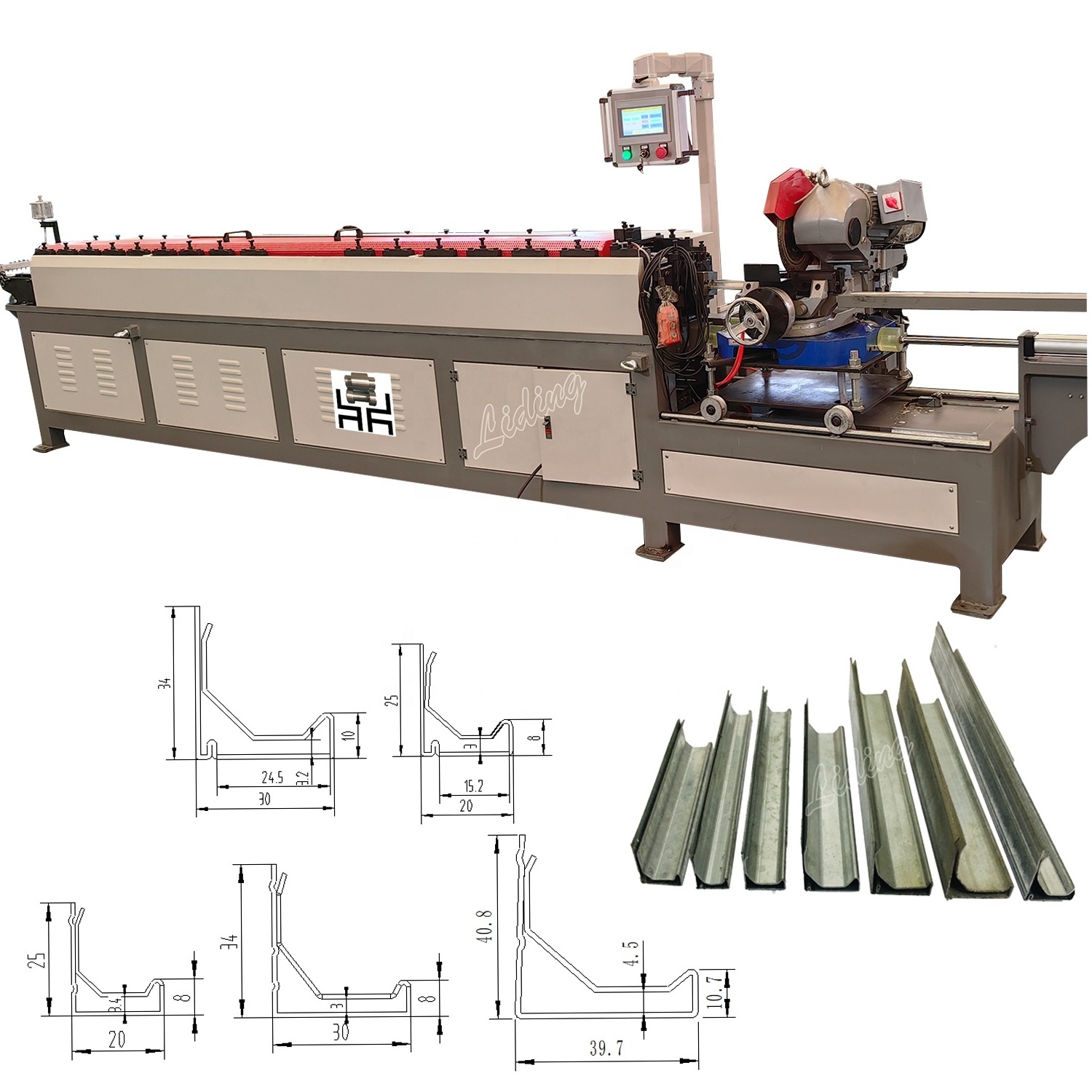

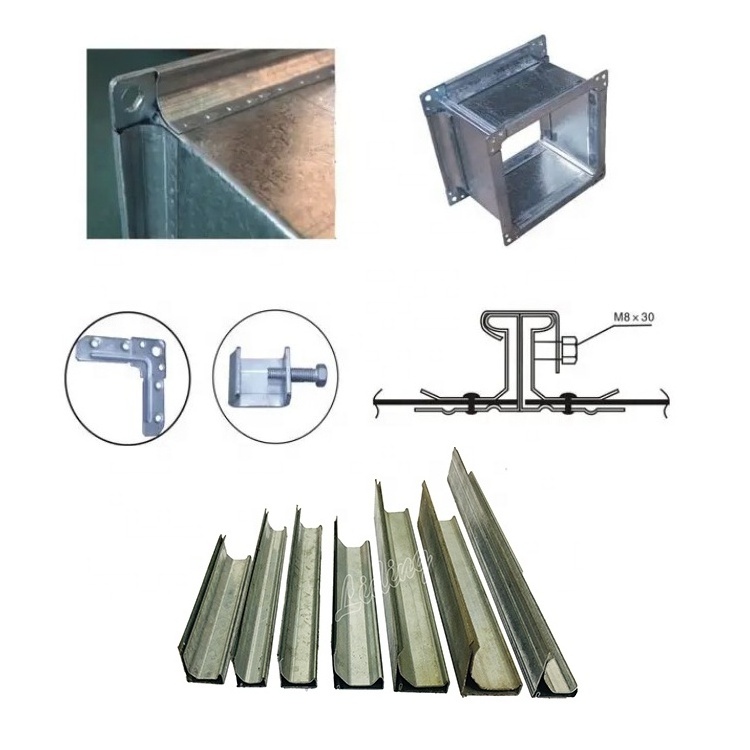

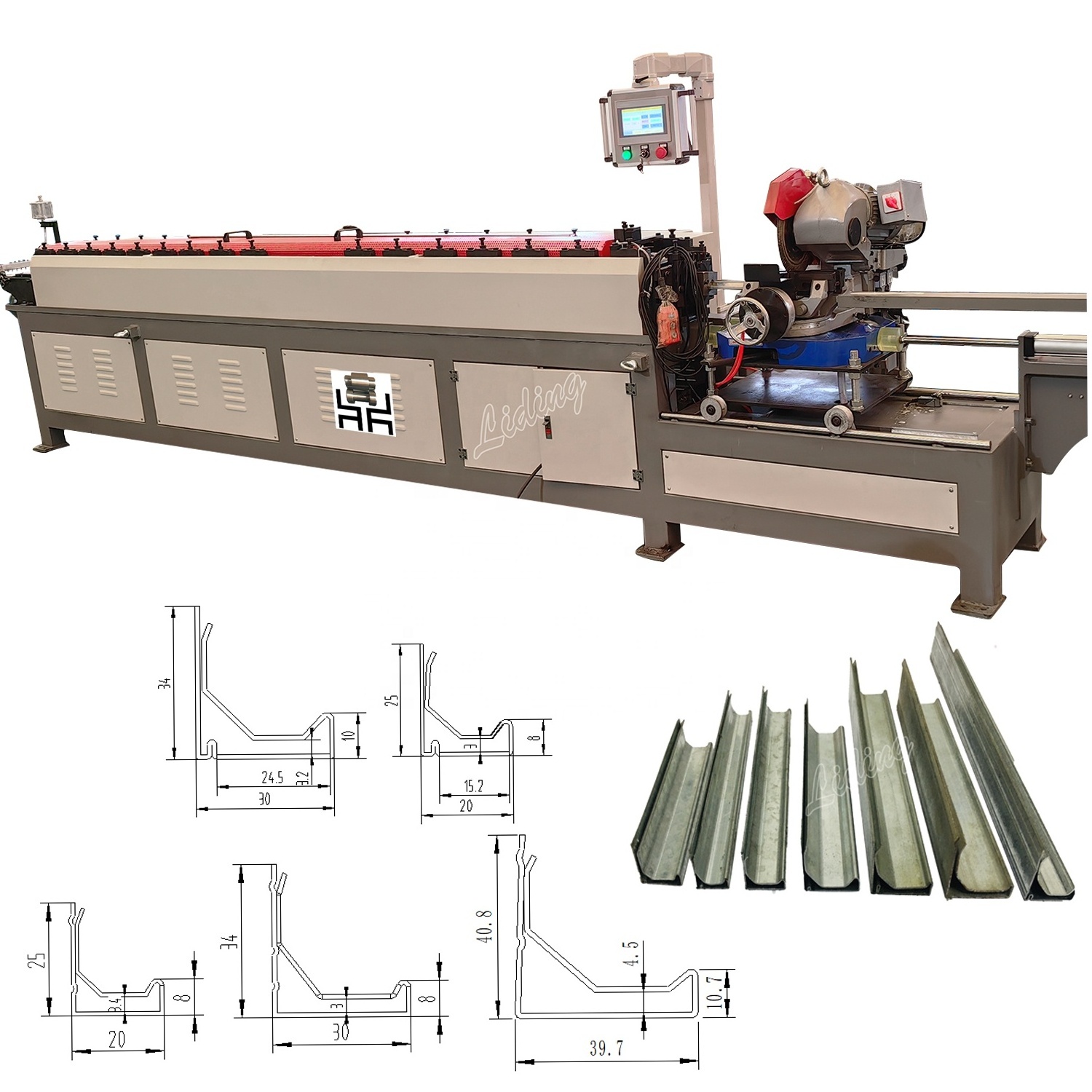

Factory Professional manufacturer tdc machine tdc flange forming machine

Mainly specification:

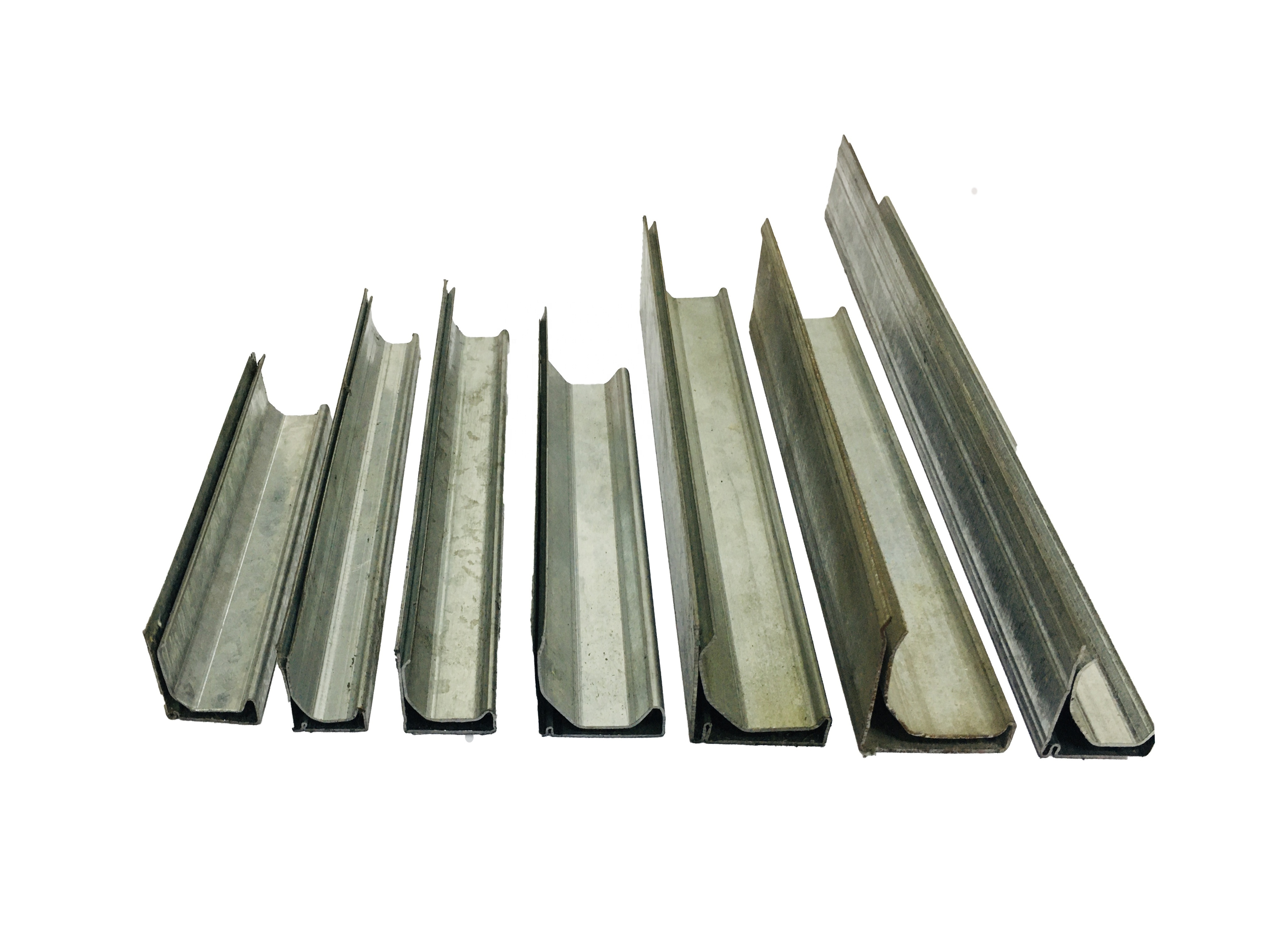

TDC flange roll former is widely used for manufacturing TDC-20mm, TDC-30, TDC-40 wide side on frame flange etc. custom TDC flange profiles can be offered on request. The ship on flange lines can also be equipped with a device for injection of sealing mastic directly during the forming process.TDC flange roll former machine is consisted of decoiler, main forming units and cutting system. The cutting system is automatic cutting with high cutting speed up to 6-10m/min.

Product Specifications

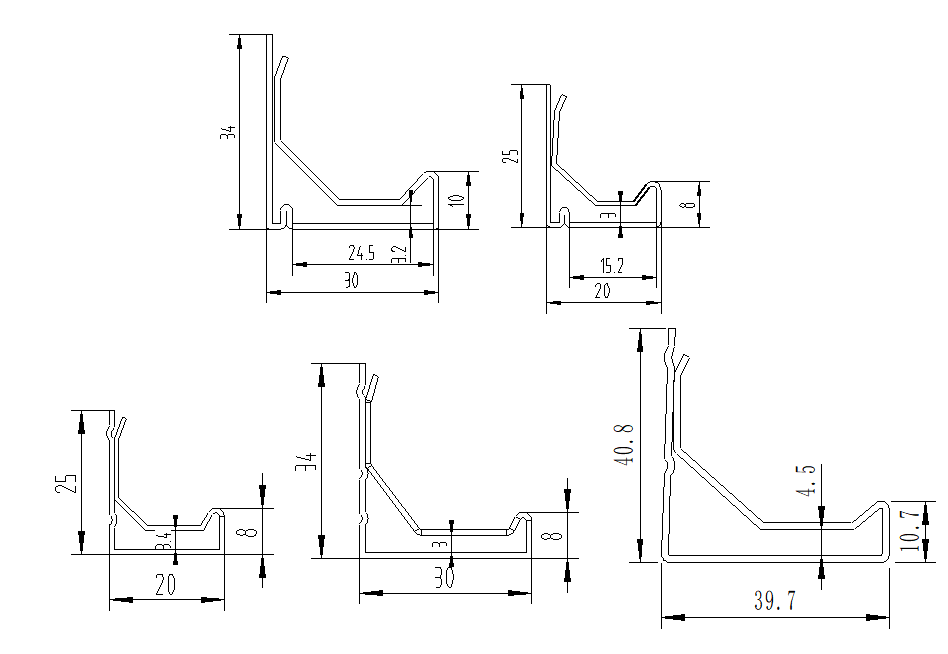

T-30 tdc machine tdc flange forming machine details:

|

No

|

Item

|

Date

|

|

1

|

Decoiler

|

1 set

|

|

2

|

Roll Forming Machine

|

1 set

|

|

3

|

Circular steel sawing

|

1 set

|

|

4

|

Run Out Table

|

4 m

|

|

5

|

PLC controling

|

PLC control system with touch screen

|

Producing process

Decoiling → Feeding → Roll forming →Circular steel sawing-off →Run-out table

Details Images

20 years of production experience to provide customers with solutions

tdc flange production line

Name: Decoiler

The guiding position can be adjusted for suitable material feeding.

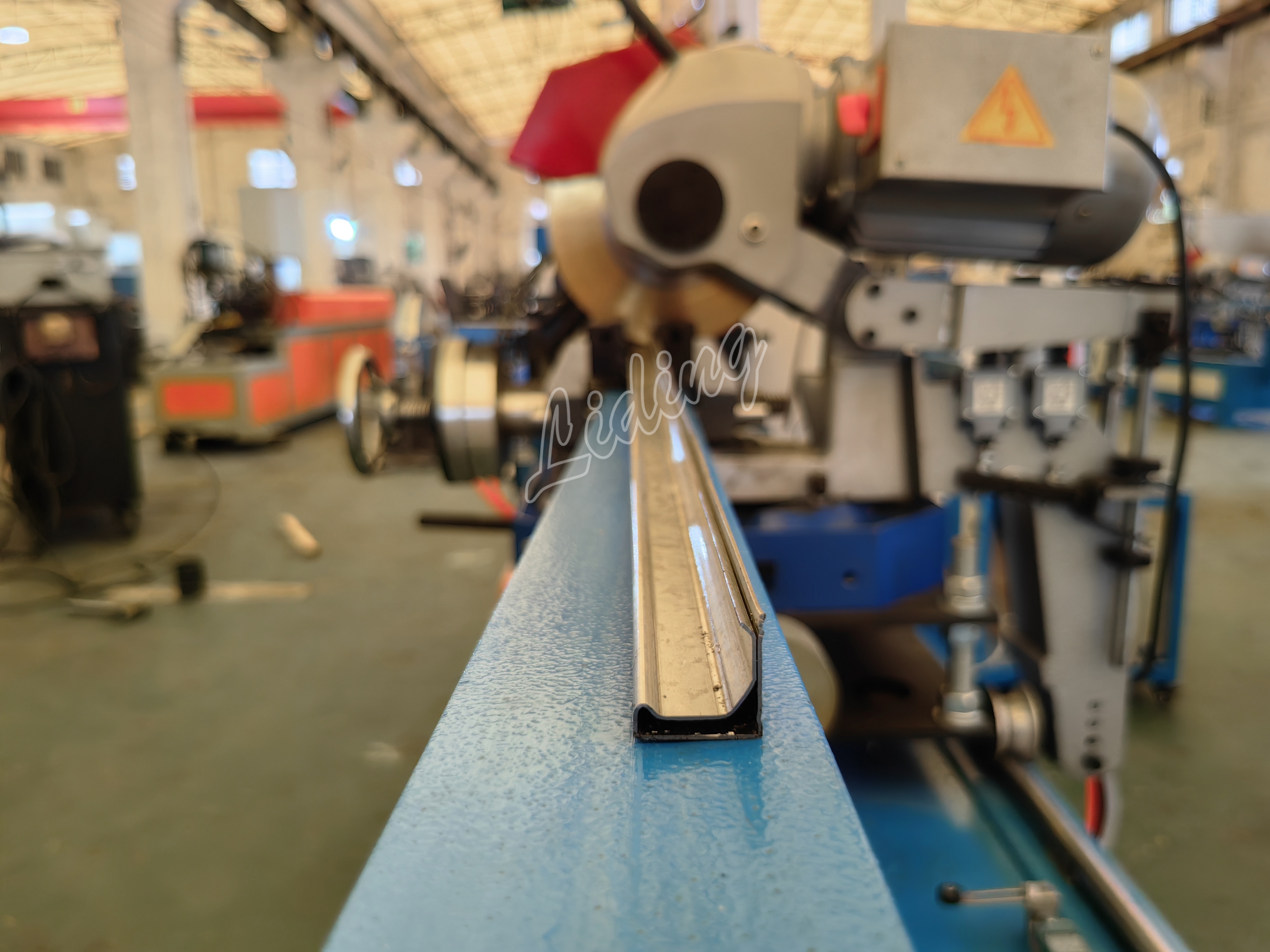

Name:

Guilding and roll forming system

Original:

Guangdong

, China (mainland)

The rollers, shafts and cutters are made by excellent raw material and they are installed by our professional engineers.

The rollers, shafts and cutters are made by excellent raw material and they are installed by our professional engineers.

Name: PLC Control System

Brand:

Panasonic plc

Automatic control of quantity and cutting length.Inputting production data on the touch screen (production batch, quantity, length, etc.),it can automatically complete the production.

The main electrical parts adopt Schneider and Shihlin products.

The length is measured by the internal secret control encoder。

The electric control box adopts fully sealed ventilation and cooling device.

Name:

Circular steel sawing and cutting

Original: Guangdong, China (mainland)

①hydraulic motor 2.2KW

②

275 circular steel saw blade 1 piece

③

Saw blade Material:

Treatment hardness HRC60°-62°

④

Using online encoder to detect stopping and cutting

After cutting on the support table, we will fix the pneumatic stopper to control the length, so the support table will move together with cutting device

Hot Searches