- Product Details

- {{item.text}}

Quick Details

-

Insulation Material:

-

Enameled

-

Place of Origin:

-

Jiangsu, China (Mainland)

-

Brand Name:

-

SZ CABLE

-

Model Number:

-

Enameled aluminum flat wire

-

Diameter::

-

0.1mm*1mm

-

Color::

-

Natural or as customer's requirement

-

Certification::

-

ISO9001

-

Insulation::

-

PEW,UEW,EIW,AIW,EI/AIW

-

Delivery time::

-

7-30 days

-

Thermal Class::

-

130-220℃

-

Advantages::

-

High conductivity,Good solderability,High ductility

Quick Details

-

Application:

-

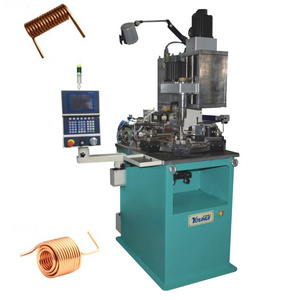

Motor, Transformer,Rectifier and such coil conductor material

-

Conductor Material:

-

Aluminum

-

Conductor Type:

-

Solid

-

Insulation Material:

-

Enameled

-

Place of Origin:

-

Jiangsu, China (Mainland)

-

Brand Name:

-

SZ CABLE

-

Model Number:

-

Enameled aluminum flat wire

-

Diameter::

-

0.1mm*1mm

-

Color::

-

Natural or as customer's requirement

-

Certification::

-

ISO9001

-

Insulation::

-

PEW,UEW,EIW,AIW,EI/AIW

-

Delivery time::

-

7-30 days

-

Thermal Class::

-

130-220℃

-

Advantages::

-

High conductivity,Good solderability,High ductility

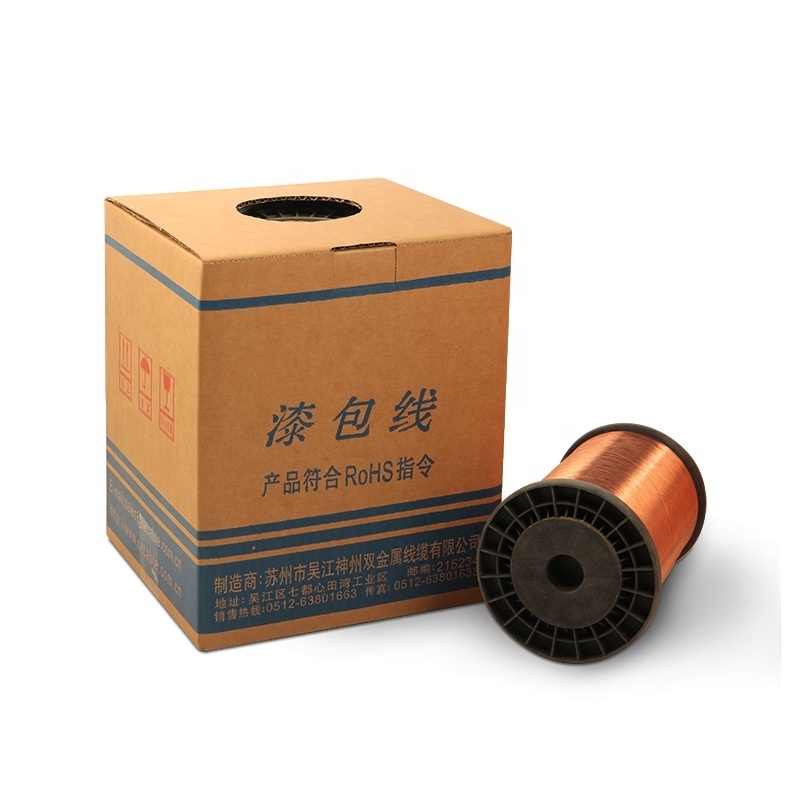

Enameled copper wire

Use pure copper wire as conductor , and covered with insulating material(such as UE, PE,EI,AI) in high temperature oven. Enameled copper wire has the characteristic of high break down voltage and high strength.

Advantage of enamel copper wire

a) Conductors have good ductility when winding

b) Good electrical conductivity

C) High strength with tensile strength of 250MP-280MP

SIZE: 0.10-5.00mm(Diameter)

Conductor: Copper(>99.97% pure)

Thermal Class: 130/155/180/200/220 centigrade

Enamel thickness: GRADE1,2,3

Coating:UE, PE,EI,AI,SELFBONDING, QA,QZ,QZY,QXY,N

Packing:

Plastic Spool: PT-4,PT-10,PT-15,PT- 25,PT- 35,PT-45,PT-60,PT-90,PT-200,PT-250,PT-270

WOOD SPOOLD: D400

Alcohol Self bonding Enamel coating process:

The enameled wire consists of bottom coating and surface coaing. Processing procedure under two enamel coating oven. The bottom coating provide the insulation performance. The surface coating can be bonded under alcohol and thermal.

The enameled wire can be used to produce alcohol and thermally stimulated windings in an integral and thus space saving, machine suitable, efficient and cost-effective manner.

Characteristic :

1-Soldering:If choose Polyurethane enamel for bottom coating, the wire can be solderable.

Working temperature: Normal 130-180 degree

Soldering temperature: 360-450 Centigrade

2-Polyurethane enamel wire Can apply to different colors

Color application: RED, BLACK, BLUE, GREEN, GOLDEN, YELLOW,SILVER

3-Low dielectric loss at high frequency;

For this Characteristic, the Polyurethane enamel wire are widely used in high frequency electrical appliances, such as high frequency inductor, high frequency transformer.

4-High temperatuer performance:

Thermal properties depend on the type of bottom coating. Temperatuer can be from 130-240 degree.

Application:

Electromagnetic Furnace Wire Disc,Drives for household appliances, mutual inductor,pole windings, power tools, coils for the speakers

|

Type

|

Polyester

|

Modified Polyester

|

Polyurethane

|

Polyesterimide

|

Polyamide-imide

|

Polyamide

|

|||||

|

Code

|

PEW, QZ

|

PEW, QZ

|

UEW, QA

|

EIW, QZY

|

EI/AIW, QZY/XY

|

AIW, QXY

|

|||||

|

Thermal Class

|

Class B, 130℃

|

Class F, 155℃

|

Class F, 155℃

|

Class H, 180℃

|

Class H, 200℃

|

Class L, 220℃

|

|||||

|

Insulation thickness

|

Grade 1, 2, 3

|

|

|

|

|

|

|||||

|

Characteristics

|

Good heat resistance and mechanical strength.

|

High mechanical strength, good elasticity, scratch resistance, adhesion, electrical properties and solvent resistance

|

Solderability(no need to remove the insulation).

|

Good thermal shock resistance and refrigerant resistance.

|

More comprehensive performance, with high heat resistance, mechanical properties, refrigerant resistance and chemical resistance

|

Highest heat class

|

|||||

|

|

Low cost.

|

|

High frequency resistance and dyeability

|

Excellent chemical resistance, abrasion resistance

|

|

High heat resistance, good solvent and refrigerant resistance

|

|||||