- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.6MM

-

Place of Origin:

-

hebei

-

Brand Name:

-

JCX

-

Voltage:

-

380v 50Hz

-

Dimension(L*W*H):

-

7*1*1.5

-

Weight:

-

3000 kg

-

Marketing Type:

-

Hot Product

-

Product name:

-

Concealed Fastener metal wall Panel roll forming machine

-

Usage:

-

Wall Panel

-

Raw material:

-

PPGI PPGL GI GL

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr12Mov Steel

-

Shaft material:

-

45# Steel Outer Diameter: 60mm

-

Control system:

-

PLC(imported Brand)

-

Cutting type:

-

Automatic Hydraulic Cutting

-

Control box language:

-

Add Customer Request Language

-

Roller stations:

-

16 Stations

Quick Details

-

Type:

-

roll forming machine

-

Tile Type:

-

metal wall Panel

-

Production Capacity:

-

8-12m

-

Rolling thinckness:

-

0.3-0.6MM

-

Place of Origin:

-

hebei

-

Brand Name:

-

JCX

-

Voltage:

-

380v 50Hz

-

Dimension(L*W*H):

-

7*1*1.5

-

Weight:

-

3000 kg

-

Marketing Type:

-

Hot Product

-

Product name:

-

Concealed Fastener metal wall Panel roll forming machine

-

Usage:

-

Wall Panel

-

Raw material:

-

PPGI PPGL GI GL

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr12Mov Steel

-

Shaft material:

-

45# Steel Outer Diameter: 60mm

-

Control system:

-

PLC(imported Brand)

-

Cutting type:

-

Automatic Hydraulic Cutting

-

Control box language:

-

Add Customer Request Language

-

Roller stations:

-

16 Stations

Concealed Fastener metal wall Panel Perforated Holes horizontal metal wall panel Siding Systems roll forming machine

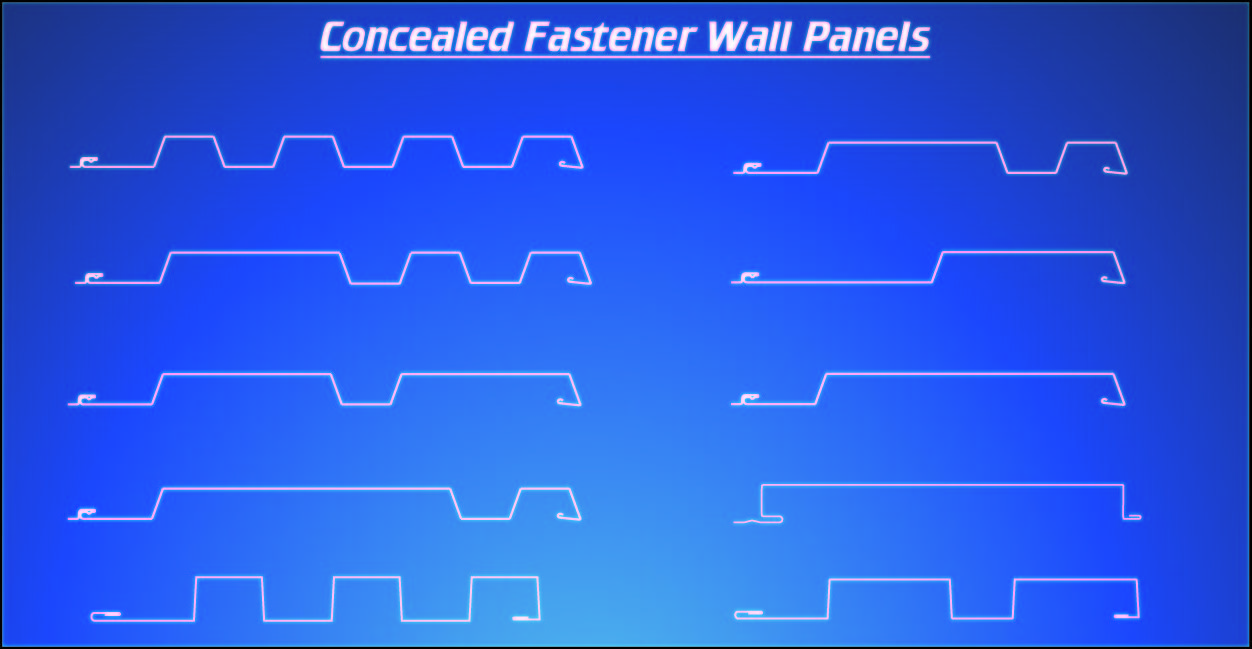

Concealed Fastener metal wall Panel Perforated Holes horizontal metal wall panel Siding profile drawing

Concealed Fastener horizontal metal wall panels Metal exterior wall sheet

application

Concealed fastener wall panels are attached to the substructure without visible fasteners. Instead, concealed fastener panels are installed with clips and/or screws hidden behind the face of the panel.

Due to narrower cover widths and increased installation costs, concealed fastener systems are more costly than exposed fastener panels.

Due to narrower cover widths and increased installation costs, concealed fastener systems are more costly than exposed fastener panels.

Concealed Fastener horizontal metal wall panels Metal exterior wall sheet roll forming machine

working

flow

Concealed Fastener metal wall Panel Perforated Holes horizontal metal wall panel Siding Systems roll forming machine

parameter

|

Raw material

|

Aluminium, color steel

|

|

|

Material thickness

|

0.4-0.6mm

|

|

|

Voltage

|

220V 60Hz 3 Phase or as your request

|

|

|

Main power

|

5.5Kw

|

servo motor

|

|

Hydraulic power

|

4Kw

|

|

|

Working speed

|

12-18m/m

|

|

|

Control system

|

PLC delta

|

Siemens,Mitsubishi, panasonic (Optional)

|

|

Machine main structure

|

Wall panel structure

|

Cast iron structure (Optional)

|

|

Roller station

|

16 Forming stations

|

|

|

Roller material

|

#45 steel

|

heat treatment,hard chrome plating after finishing,

mirror polishing. |

|

Shaft

|

#45 steel

|

CNC machining processing, heat treatment to HRC28-32, fine machining

|

|

Driving system

|

Chain drive

|

Gearbox (Optional)

|

|

Cutting system

|

hydraulic cutting

|

servo tracking cutting (optional)

|

|

Cutting blade material

|

Cr12mov,

Quenched treatment 58℃-60℃

|

|

|

Decoiler

|

3 ton manual decoiler

|

Hydraulic decoiler (Optional)

|

Concealed Fastener metal wall Panel Perforated Holes horizontal metal wall panel Siding Systems roll forming machine

component introduction

①Positioning plate:adjust the position of both ends to make it fit the width of the feed.

②Guide frame:play a role in supporting the transport of the material roll

③Guide roller:The upper and lower round roller design makes the feeding process smoother.

cutting system

Machine rollers all be high grade 45# steel(plated chrome on surface), the roller precision process by our own CNC machine, which can control the roller quality and precision, ensure the product size accuracy and shape beautiful.

Control system

PLC brand:Delta(Taiwan) PLC, and transducer and touched screen ● Encoder brand:Omron ● Electrical components:Schneider ●Operating language:English and Chinese(or as requested) You can set the orders on this part,changing product length and quantity,it is really easy to operate,and there are aviation plugs to make it much easier to install the machine while it arrived.

Low voltage electrical appliances: SCHNEIDER

hydraulic station

Hydraulic oil into the hydraulic oil tank

Pump motor drives the cutter work

Motor Power: 4KW

Hydraulic oil: 46# Oil

add capacity: oil add 3/4 of box capacity

Decoiler

Usage: Mainly used to support steel coils, and manually uncoil and straighten the coil into the feeding table.

Loading capacity: 3T

Inner diameter: 500-508mm

Optional component

Electric cutting

Cast iron structure

Servo motor

Protect cover

hydraulic decoiler

full automatic stacker

Other related machines

Concealed Fastener metal wall Panel Perforated Holes horizontal metal wall panel Siding Systems roll forming machine

Features

-High efficiency

high-speed,low-labor process that enables efficient and high-volume production.Additional processes like punching or notching can be integrated into the rollforming production line,reducing labor demands and producing finished products.

-Energy-saving and waste-reducing

Roll forming is a no-heat process that uses custom-designed rollers to gradually bend metal intoits final shape,reducing energy costs.It eliminates tool wear and produces identical parts withminimal wasted scrap and allows for almost any length.

-Faster production times

Roll forming enables faster production times due to its high-speed,continuous process andminimal labor requirements,resulting in efficient and rapid production of consistent and high-quality products

Machine Shipping

Before loading to the container, we will check the machine first

Second, make some protection on the machine, Such as, we will paint the coil on the roller and shaft, in case the roller and shaft got corrosion and rusty during long time delivery

Third, we will make the plastic package on the easy damage parts, and fix all the parts into container by the steel wire ropes, and ensure the machine will not damage when shaking on sea.

At last, we will take photos for customer when loading to container

What should I provide if I`d love to customized my machine?

1. Profile drawing

2. Raw material: the width(333mm?), thickness(0.3-0.7mm?), and yield strength of steel coil.

3. Voltage: designed per your requirement

4. Configuration requirement: Hydraulic or manual decoiler/ stacker

Have no idea about them?

We will be glad to recommend machines ----Just let us know your country!

Any questions, please contact with us directly, We will try best to help you.

Why choose us?

1.We are a factory with nearly 20 years experiences on Roll Forming Machines, We have our own research and development team with strong ability to solve all kinds of problems;

2. We have Laser Cutting Machine, CNC Machining Center, Polishing Line, Painting Line, etc. advanced production equipments to ensure the quality of each part and the best appearance of our machines;

3. We have stable raw material suppliers to ensure the best quality and on time supplying with low cost;

4. We have got the ISO9001:2008 Certificate and CE Certificate;

5. We have more than 20 technicians that can go abroad for the after-sale service;

6. We are always waiting to serve you 7 days a week and 24 hours a day.

7. About the shipment, we have several long cooperated forwarder who can quote us the lowest sea freight . if you need us to ship for you, i can give u the best suitable sea freight . You don't need to worry about you can not deal with the shipment. Also , you can choose your own forwarder and I will cooperate with them throughout.

Hot Searches