- Product Details

- {{item.text}}

Quick Details

-

Roller Number:

-

4

-

Max Input Size:

-

30mm

-

Particle Size:

-

80-400 mesh

-

Service Provided:

-

Engineers available to service machinery overseas

-

Spare parts supplying:

-

Lifelong Provide

-

Production Line Design:

-

Can design production line according to your requirement

-

Market feedback:

-

High reputation by customers in china and overseas customers

-

Processed Materials:

-

Cement, Gypsum, Talc, Limestone, Coal etc.

Quick Details

-

Place of Origin:

-

Guangxi, China

-

Name:

-

Stone Grinding Raymond Mill

-

Application:

-

Mining, Chemical, Metallury, Building Materials etc.

-

Roller Number:

-

4

-

Max Input Size:

-

30mm

-

Particle Size:

-

80-400 mesh

-

Service Provided:

-

Engineers available to service machinery overseas

-

Spare parts supplying:

-

Lifelong Provide

-

Production Line Design:

-

Can design production line according to your requirement

-

Market feedback:

-

High reputation by customers in china and overseas customers

-

Processed Materials:

-

Cement, Gypsum, Talc, Limestone, Coal etc.

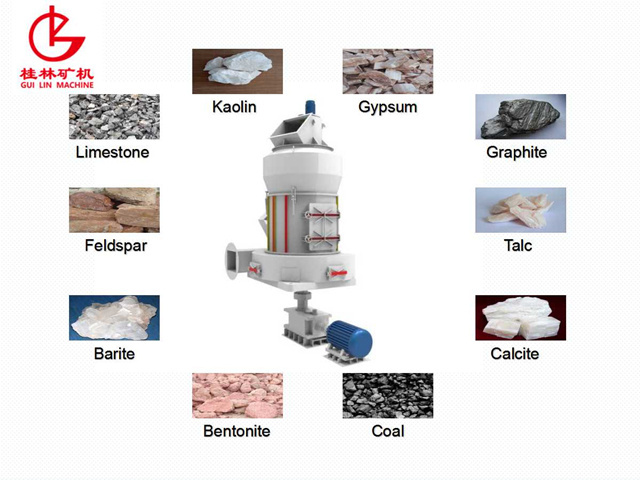

Application Area

Mainly used in Mining, Metallurgy, Chemical Industry, Building Materials, Highway, Railway, Water Conservancy etc., suitable for processing hardness under seven levels, humidity under 6%, all kinds of inflammable and explosive mineral and rock.Such as calcite, limestone, marble, dolomite, talc, barite, kaolin, bentonite, feldspar, quartz, lime, graphite, silicon carbide, wollastonite, gypsum, bauxite, zircon sand, coal, manganese ore, phosphate rock, fly ash, slag, cement etc.. Below are some material in application:

|

|

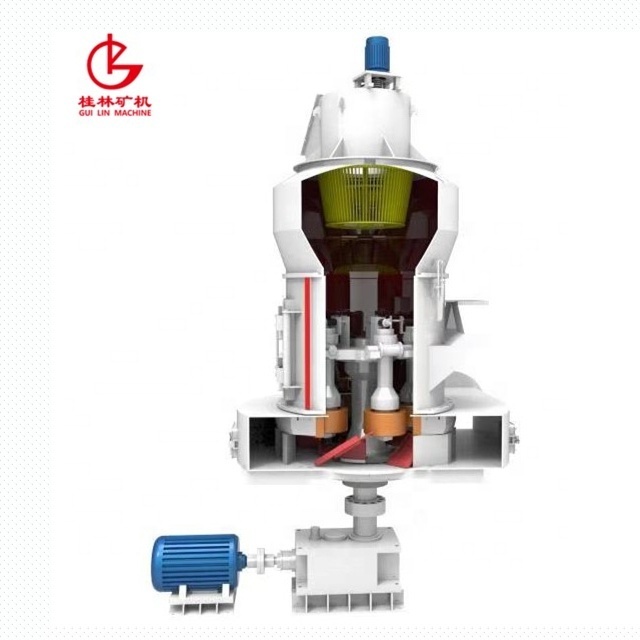

High Output & Low Consumption Compared with same capacity φ1250 vertical mill, 1/4 power saving. Compared with normal Raymond mill, same with total outlet of 6 pcs 4R3216, also 1/4 power saving. >Click Here to Get More Detail Information

Less Floor Space Floor space total 153 spm compared with same output and granularity, 1/3 floor space saving than 6 pcs 4R3216 Raymond mills (1pc takes 56sqm). So will reduce investment in infrastructure. >Click Here to Get More Detail Information

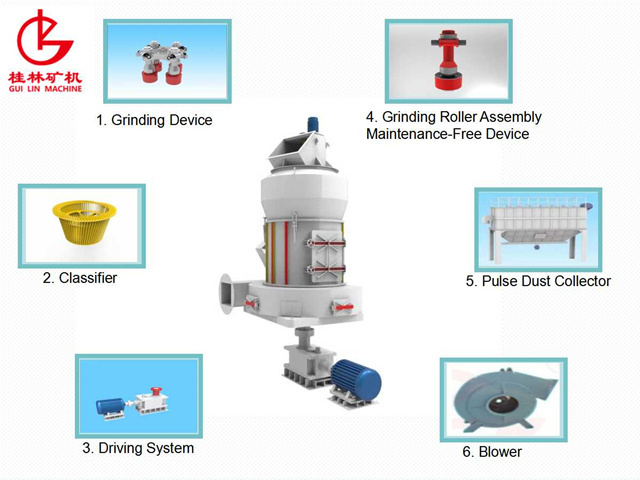

Maintenance-free Grinding Roller Assembly Innovative design of the "maintenance-free device" for grinding roller assembly, refil oil every 30 days. Ordinary roller assembly refil oil once every 1-2 days. >Click Here to Get More Deatil Information

Large Transmission Capacity Blower adopts high pressure centrifugal fan to increase air volume and air pressure, so as to greatly improve the ability of pneumatic conveying. >Click Here to Get More Detail Inofrmation

High Collection Efficiency Cyclone collector adopts parallel double cyclone collector, 10-15% higher than the single cyclone collection efficiency. >Click Here to Get More Deatil Information

High Classification Accuracy Classifier adopts built-in large taper blade turbine classifier. The outlet fineness can be adjustable from 80-400 mesh. >Click Here to Get More Detail Information

Strong Ability of Shoveling Material Adopting super large shovel blade to shovel as much as possiable of the material to the grinding area between the roll and ring. >Click Here to Get More Detail Information

Energy Conservation & Environment Protection Equipped with pluse dust collector in surplus wind outlet, collection efficiency is as high as 99.9% to keep workshop environmental health. >Click Here to Get More Deati Information

|

Main Technical Parameters

>Click Here To Get More Detail Information

Spare parts are placed and fixed orderly,then packed with wooden case. Equipment would be processed to be rustproof and moisture proof before delivery. All equipment would be transported to loading port by truck. Professional transporter will load the equipment into containers tightly , ensuring the goods withstand long distance transportation. Clients will be informed all process details, then clients call know how is going on with the goods.

Customer Case