- Product Details

- {{item.text}}

Quick Details

-

Min.Thickness of Die Block (mm):

-

1 mm

-

Ejection Force(kN):

-

1 kN

-

Ejection Stroke(mm):

-

1 mm

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

DL Die Casting Machine

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2250 x 2160 x 1560 mm

-

Weight (KG):

-

2000

-

Power (kW):

-

5.5

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Type:

-

brass die casting machine

-

Application:

-

Precision Casting Industry

-

Weight of the largest model:

-

130 kg

-

Largeat Merger Distance:

-

500mm

-

Feature:

-

Efficient

-

Material:

-

Brass,Stainless Steel,aluminium,zinc

-

Technology:

-

Die Casting Technology

-

Usage:

-

Upward Continuous Casting

-

Features:

-

Simple Operations

Quick Details

-

Machine Type:

-

gravity brass die casting machine

-

Marketing Type:

-

brass die casting machine

-

Max.Thickness of Die Block (mm):

-

1 mm

-

Min.Thickness of Die Block (mm):

-

1 mm

-

Ejection Force(kN):

-

1 kN

-

Ejection Stroke(mm):

-

1 mm

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

DL Die Casting Machine

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2250 x 2160 x 1560 mm

-

Weight (KG):

-

2000

-

Power (kW):

-

5.5

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Type:

-

brass die casting machine

-

Application:

-

Precision Casting Industry

-

Weight of the largest model:

-

130 kg

-

Largeat Merger Distance:

-

500mm

-

Feature:

-

Efficient

-

Material:

-

Brass,Stainless Steel,aluminium,zinc

-

Technology:

-

Die Casting Technology

-

Usage:

-

Upward Continuous Casting

-

Features:

-

Simple Operations

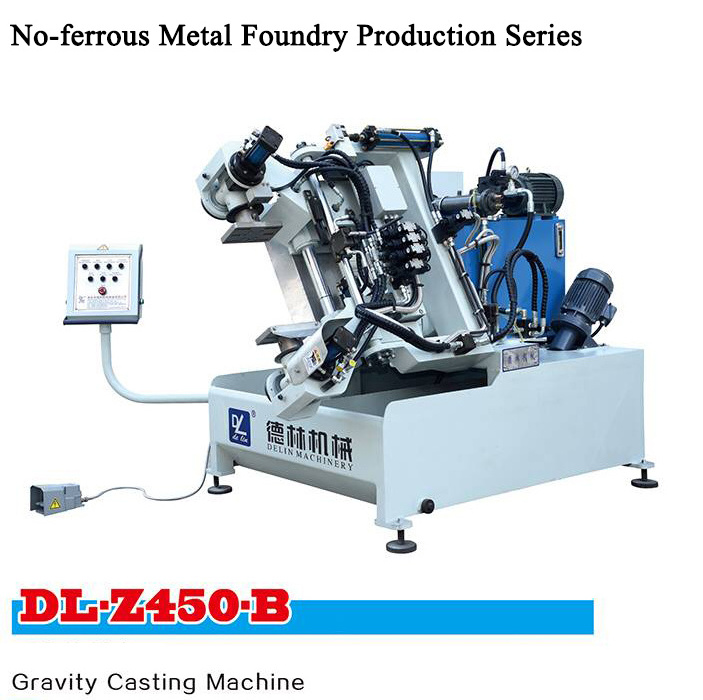

1. Die Casting Machine Main Function Features

Machines are suitable for producing plumbing fittings,hardware,sanitary ware,auto parts which gravity model casting with brass,zinc,aluminium,steel,iron ore and alloy,ferrous metal and non-ferrous metal.

(1) Circuits are all controlled by PLC,data setting adopts touch screen ,electrical components are

imported from Japan and hydraulic components are as well imported from outside.

(2) For gravity model casting with brass and ferroalloy.

(3)Front casting,lateral casting and secondary casting are optional.

(4) Individual cooling time of model is adjustable.

(5) The dismantling ,assembly and cleaning of model are convenient.

(6) Two functions of manual and automatic circulation are available.Totalizing counter and preset

counter are arranged to record the piece number of on duty production.

(7) Adjustment range of model is defined to make the using of different models easy and reduce

requirement of model's exterior physical dimension.

(8) This casting machine can store 100 sets model casting operation programs and you can set your

password.

2. Casting Macine Specification

| Biggest Size of The Mould | Φ 550 mm |

| Heaviest Weight of The Mould | 150 kg |

| Largest Merger Distance | ≤ 280 mm |

| Hydraulic Pressure | 40 - 60 kPa |

| Angle of Lateral Casting | 0° - 90° |

| Frontal Casting Angle | 0° - 110° |

| Hydraulic Lube | 165 L |

| Net Weight of The Whole Machine | 2000 kg |

|

Size of Appearance of Machine ( L * W * H ) |

2350 × 2100 × 1860 mm |

| Installing Top Core Available | Itinerary of Top Core 20 mm |

| Total Power | 5.5 kw |

* some parameters can be customised by client's requirement.

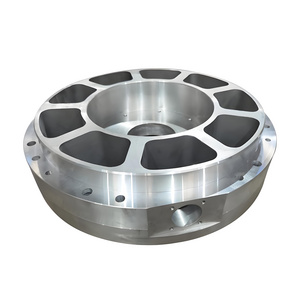

Finished Products Showing

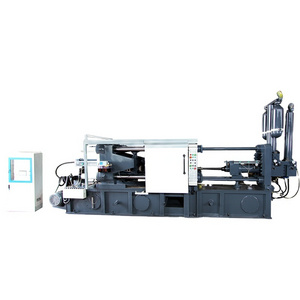

Ferrous and non-ferrous metal foundry production series

We have the whole foundry produciton line machinery,which widely used to making and processing plumbing, sanitaryware, car spares, vaives, iron cast lines and so on.

Main equipments : automatic SPM machining equipment , such as horizontal CNC drilling / milling / tapping machine ; Double head drilling and tapping machine, automatic sand moulding machine, low-pressure die casting machine, gravity casting machine, furnace, core shooting machine, mixing sand machine, shot blasting machine (abrator),polishing machine etc.