- Product Details

- {{item.text}}

Quick Details

-

Power:

-

380kw

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

20000 kg

-

Mixer type:

-

Twin-shaft forced mixer

-

Productivity:

-

80-160t/h

-

Burner:

-

coal/diesel / oil

-

Air Emissions:

-

≤20mg/Nm3

-

Color:

-

White, blue, green or customized

-

Fuel consumption (standard conditions):

-

5-7.5kg/t finished product

-

Hot Asphalt temperature:

-

130-170°C

-

After Warranty Service:

-

Spare Parts Delivery

-

After-sales Service Provided:

-

Online Video Technical Support

-

Mixing Type:

-

Hot Asphalt Batching Plant

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Chenli

-

Voltage:

-

Customized

-

Power:

-

380kw

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

20000 kg

-

Mixer type:

-

Twin-shaft forced mixer

-

Productivity:

-

80-160t/h

-

Burner:

-

coal/diesel / oil

-

Air Emissions:

-

≤20mg/Nm3

-

Color:

-

White, blue, green or customized

-

Fuel consumption (standard conditions):

-

5-7.5kg/t finished product

-

Hot Asphalt temperature:

-

130-170°C

-

After Warranty Service:

-

Spare Parts Delivery

-

After-sales Service Provided:

-

Online Video Technical Support

-

Mixing Type:

-

Hot Asphalt Batching Plant

Simple Structure Construction Machinery Portable Asphalt Mixing Plants

portable asphalt mixing plants

is a kind of equipment that mixes stone, asphalt and mineral powder according to a certain proportion to produce asphalt mixture. Compared with the stationary asphalt mixing plant, the unique walking system makes the transition more convenient.

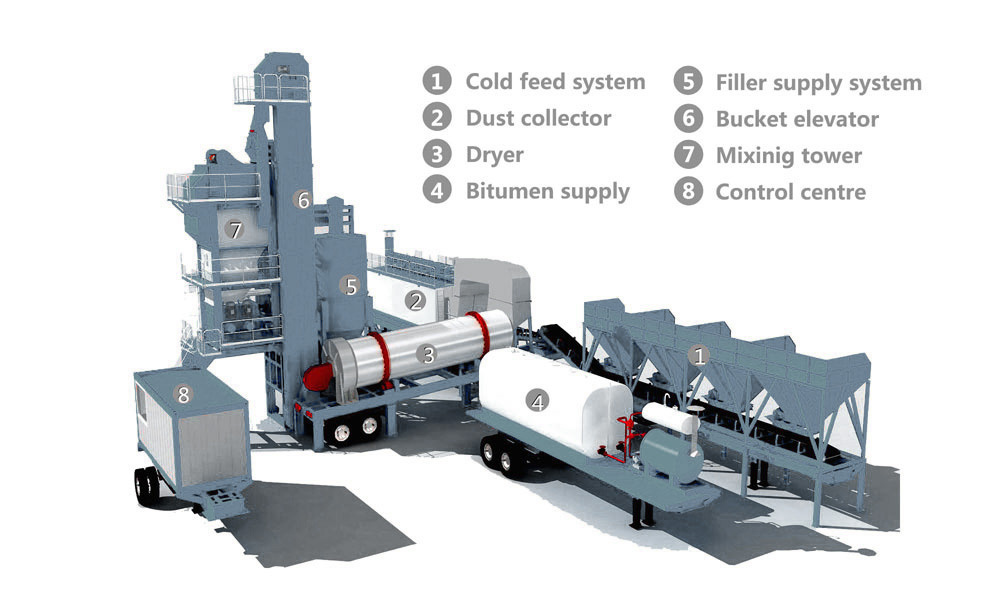

The components and workflow of a mobile asphalt forced mixing plant are basically the same as those of a stationary asphalt mixing plant.

During the drying process, the dust and moisture contained in the cold aggregate are sucked into the bag dust collector.

The hot aggregate heated by the drum dryer passes through the hoist to the vibrating screening system above the mixing building. They are screened into different specifications by the vibrating screen, and then respectively enter the storage hopper below. Afterwards, according to different ratios, they are put into the weighing device in turn and re-weighed.

The mineral powder is transported to the temporary storage hopper through the powder elevator, and then to the weighing device for weighing. At the same time, the bitumen is sent to the bitumen metering device through the pipeline for weighing.

Later, put the weighed aggregate, mineral powder and asphalt into the twin-shaft mixer in turn for mixing. When the specified time is reached, open the discharge door of the mixer. And put the evenly stirred mixture into the finished product warehouse. Finally, the mixture is put into the dump truck and transported to the construction site.

| Model | Rated capacity(t/h) | Measure accuracy(static)% | Dust concentration | ||

| Bitumen | Filler | Aggregate | |||

| LBY1000 | 80 | ±0.25% | ±0.5% | ±0.5% | ≤50mg/Nm3 |

| LBY1500 | 120 | ±0.25% | ±0.5% | ±0.5% | ≤50mg/Nm3 |

| LBY2000 | 160 | ±0.25% | ±0.5% | ±0.5% | ≤50mg/Nm3 |

The parameters in the table are incomplete. Click here for more details.

1. The portable asphalt mixing plants is compact and integrates a complete set of equipment for asphalt concrete production on several trailer units.

Because the portable asphalt mixing plants adopts a forced mixer, the cold aggregate and asphalt can be fully mixed, so the quality of the finished product is relatively good. The finished product of portable asphalt mixing plants is usually used to build expressways and airport roads with strict quality requirements. The portable asphalt mixing plants has the characteristics of high degree of automation, high finished product specifications, and convenient transportation.

Tai'an Chenli Construction Machinery Co., Ltd. is a technology-based company focusing on the development, design, manufacturing, engineering and service of intelligent complete equipment for building materials. Based on a deep understanding of building intelligent equipment, Taian Chenli is committed to providing users with "practical, efficient, low-carbon, environmentally friendly, intelligent and advanced" intelligent equipment products. In line with the product concept of "excellence in quality, simplicity to the extreme", committed to the high-tech development and application of intelligent equipment, energy-saving and environmentally friendly equipment for new building materials. The current leading products are cement concrete batching plants, mortar production lines, tower type sand making machine, and environmental protection equipment for batching plants. The products win the trust of the market with high standards and high reliability, and are deeply trusted by users.