- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

PTFE Rod

-

Appearance density g/cm3:

-

2.10-2.30

-

Tensile strength (min) MPa:

-

18

-

Crack elongation (min) %:

-

230

-

processing:

-

Extruded/Molded

-

diameter mm:

-

1- 500 mm

-

Length:

-

customize

-

hardness shore:

-

65-70

-

working temperature:

-

-180-+270

-

Electric strength:

-

≥10 kv/mm

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ZhaoNM

-

Model Number:

-

ZT-PTFEGK01

-

Product name:

-

PTFE Rod

-

Appearance density g/cm3:

-

2.10-2.30

-

Tensile strength (min) MPa:

-

18

-

Crack elongation (min) %:

-

230

-

processing:

-

Extruded/Molded

-

diameter mm:

-

1- 500 mm

-

Length:

-

customize

-

hardness shore:

-

65-70

-

working temperature:

-

-180-+270

-

Electric strength:

-

≥10 kv/mm

Product Description

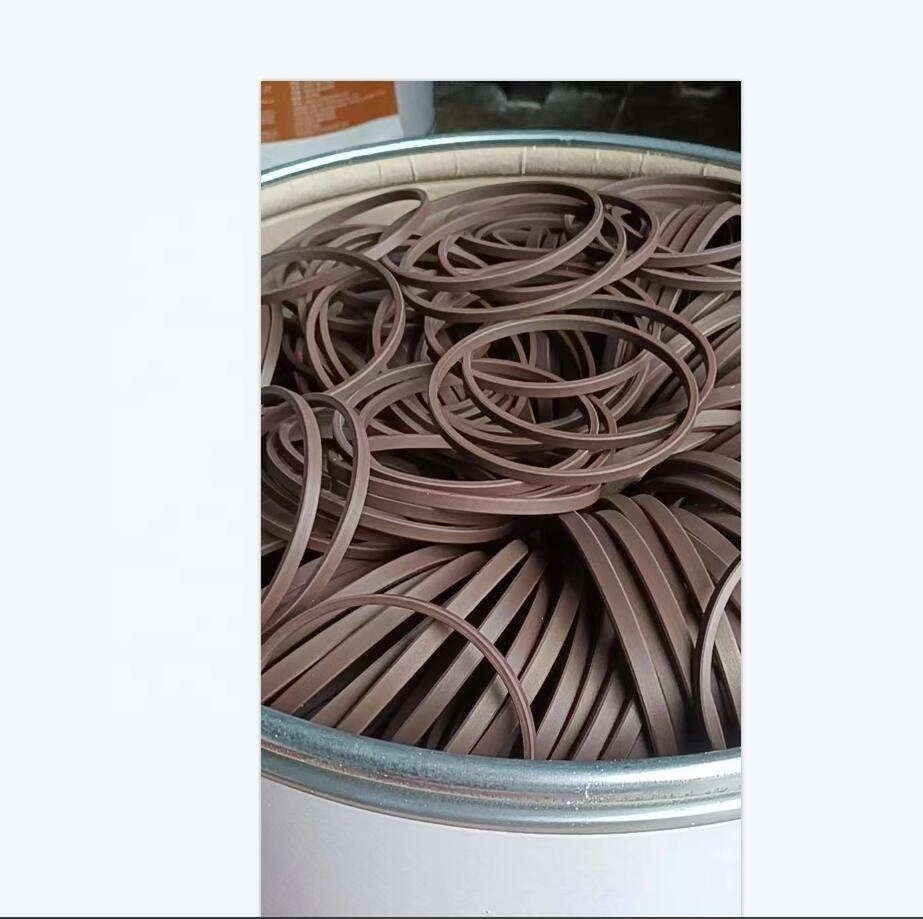

PTFE GASKETS

come in all shapes and sizes,Gaskets are an integral component of any device which requires the confinement of a gas or liquid. They compensate for the unconformity of mating surfaces. These surface irregularities may be minute or large depending on the purpose of the device but in all cases, the gasket is required to compensate for the difference while limiting the flow of fluid in either direction. Gaskets differ from seals in that gaskets are normally cut from sheets or rolls while seals are formed individually in their own configuration. A flat cut gasket is derived from material of specific thickness and to a configuration that is designed for a specific application

Expanded PTFE

-

EPTFE Gasket material

is a soft and conformable material that is ideal for applications with limited bolt load torque available. Or in applications such as glass lined pipe where excessive bolt load will cause more problems than it will solve. If you have never touched this exceptional sealing material think of a dense marshmallow. It has the same chemical resistance and temperature range as any PTFE but it is soft and will effect a seal much quicker than regular PTFE gasket material

Characteristics

- High and low temperature resistance(-180ºC~+260 ºC)

- Corrosion resistance(strong acid, strong alkali etc)

- Weather resistance

- High insulation

- High lubrication

- Non adhesion

- Non toxic etc

We manufactures made-to-order high performance, high quality engineered plastic components

- PTFE Ball valve seats, piston rings, seals, lips, cups.

- PTFE bearings, bushings, wear strips

- Diaphragms, insulators, lantern rings, V-rings, gaskets, washers, balls

- Custom PTFE labware including wafer dippers, containers & process vessels

- Low quantity PTFE parts and assemblies for university & commercial research projects.

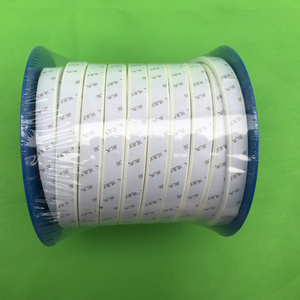

- Molded PTFE - Basic Shape material: PTFE Rod, Blocks, Plates and Tubes

- A variety of made-to-order OEM industrial component s

|

|

||||||||||||||||||||||||||||||