- Product Details

- {{item.text}}

Quick Details

-

Power:

-

4kw

-

Weight:

-

700

-

Dimension(L*W*H):

-

950mm x 650mm x 550mm

-

Product Keywords:

-

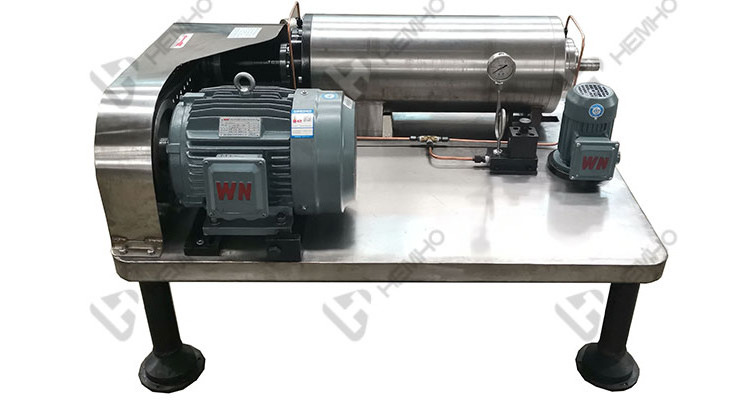

decanter centrifuge separation machine

-

Application:

-

Chemical Industry

-

Discharge type:

-

Automatic Continuous Discharge

-

Description:

-

2 Phases Separation Machine

-

Material:

-

316L Stainless Steel

-

Centrifugal type:

-

horizontal decanter centrifuge

-

Capacity:

-

5-100L/H

-

Drum Diamete:

-

80mm

-

Speed:

-

10000rpm

-

Separation factor:

-

4400

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Hemho

-

Voltage:

-

220V/380V or Customized

-

Power:

-

4kw

-

Weight:

-

700

-

Dimension(L*W*H):

-

950mm x 650mm x 550mm

-

Product Keywords:

-

decanter centrifuge separation machine

-

Application:

-

Chemical Industry

-

Discharge type:

-

Automatic Continuous Discharge

-

Description:

-

2 Phases Separation Machine

-

Material:

-

316L Stainless Steel

-

Centrifugal type:

-

horizontal decanter centrifuge

-

Capacity:

-

5-100L/H

-

Drum Diamete:

-

80mm

-

Speed:

-

10000rpm

-

Separation factor:

-

4400

HEMHO Laboratory Lab decanter centrifuge were developed specifically as two-phase decanter centrifuges for use in laboratories and pilot plants to enable small quantities of products to be processed at rates of between 1L/h to 200L/h in a continuous separation operation. The maximum throughput or feed rate depends on the separation characteristics of the specific products.

Products Description

The minimum throughputs of industrial decanter centrifuges are generally far greater than the throughputs required for the quantities of products available in research laboratories. In the past, the processing stage of continuous separation therefore frequently had to be simulated with alternative batch-wise separation methods.

The laboratory decanters are used for solid-liquid separation, their principal application being the separation of liquid-based suspensions of organic and inorganic solids.

Product Details

Hemho Advantages

1,

Universal Settling Centrifuge

2, Quick disassembly and assembly within 30 minutes

3, Minimal material residue, the gap between the spiral and the drum is less than 0.3mm

4, Simple and straightforward control panel and operation

5, Compact design

Working Principle

The working principle of the decanter centrifuge is elementary. It has been known to the public for a century. The drum and spiral are supported by separate suspensions. The material enters through the inlet pipe and accelerates into the core drum body through the drum.

Separation process:

The core part consists of a cylindrical and conical rotating bucket. The force of the centrifuge makes the solid material deposit on the wall of the rotating drum.

Solid discharge:

The spiral body and the rotating drum have the same shape and angle, and the speed is slightly faster than that of the rotating drum so that the separated solid is pushed to the narrow cone end and discharged from the rotating drum. The degree of substantial dehydration depends on many factors. In addition to the material itself, it also depends on the separation time of the solid in the centrifuge and the tight cone angle of the conveying solid. In addition, the differential speed between the screw and the drum is also an important factor.

Draining:

A chuck for adjusting the depth of the liquid level is installed at the bottom of the drum. The clarified liquid flows along with the spiral cylinder to the bottom and then is collected in the liquid hopper and discharged from the machine. The depth of the clear liquid in the drum can be changed by changing To adjust the liquid stopper.

Technical Parameters

|

|

|

|

|

|

||||

Hemho Products Recommendation

Why Choose Hemho

About Hemho

Factory Glimpse

Patents&Certifications

1, 30 Years' Experience

2, Holding 40 Patents

3, Innovative R&D Team

4, Awarded as a High-tech Enterprise

5, Precise Production Line Metting the GMP Requirements

6, CE&ISO Certificated

7, 8500M2 Facilities in Strategic Location in Yangze River Delta

Manufacturing&Packing

Manufacturing Flow

Packing for Delivery

FAQ

Q: What kind of products do you have?

A:

Industrial centrifuges like screen scroll centrifuges(LWL), decanter centrifuges(LW), pusher centrifuges(HR), peeler centrifuges, top discharge centrifuges, etc.

Q: How do you control the quality?

A:

To ensure the accuracy of each part, we are equipped with a variety of professional equipment, and we have accumulated professional processing methods over the past years.

Each component before assembly needs strict control by inspecting personnel.

After all the equipment is completed, we will conduct a trial run before shipment to ensure the customers' workshop's stable running.

Q: What terms of payment does your company accept

A: Most payment methods are accepted, however, we mainly accept T/T, L/C at sight

A: Most payment methods are accepted, however, we mainly accept T/T, L/C at sight

Q: How long is your warranty period?

A: Our officially promised warranty time is 12 months after machine's commissioning.

A: Our officially promised warranty time is 12 months after machine's commissioning.

Q: The after-sale service of Hemho

A: After finishing the production, we will test the machine, take photos, videos and send them to customers via email or other instant messenger.

A: After finishing the production, we will test the machine, take photos, videos and send them to customers via email or other instant messenger.

After the commissioning in our factory, we will package the equipment by standard export package for shipment.

Engineers, sales managers and after-sales service manager will form a aflter-sale team, to follow the customers' projects.

Hot Searches