- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Weight:

-

3kg/roll

-

Appearance:

-

White

-

Thickness:

-

5um to 25um customize

-

MD tensile strength:

-

≥150

-

Material:

-

PE /PE or multi layers

-

Certificates:

-

CE,ISO9001

-

Use for:

-

Battery seperator

-

Type:

-

PP or PE or Ceramic coated

-

Width:

-

customize

Quick Details

-

Battery Size:

-

Lithium ion battery

-

Brand Name:

-

Gelon

-

Model Number:

-

GN-Separator

-

Place of Origin:

-

Guangdong, China

-

Weight:

-

3kg/roll

-

Appearance:

-

White

-

Thickness:

-

5um to 25um customize

-

MD tensile strength:

-

≥150

-

Material:

-

PE /PE or multi layers

-

Certificates:

-

CE,ISO9001

-

Use for:

-

Battery seperator

-

Type:

-

PP or PE or Ceramic coated

-

Width:

-

customize

Product Description

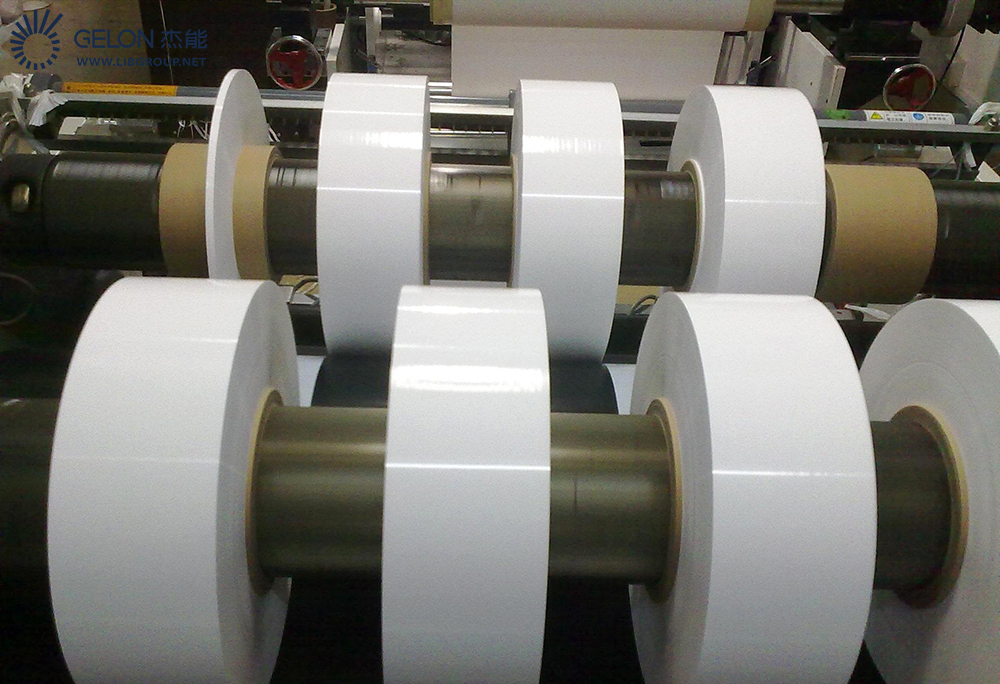

PE PP PP/PE/PP Multi layers Battery Separator with Customized Width

PE & PP separators are used for lithium-ion battery manufacturers and researchers. The materials consist of Polymer film , that are either Polypropylene (PP) or Polyethylene (PE) based. contain micro and nano pores to provide excellent ion transportation capabilities within the li-ion battery.

PE & PP separators are used for lithium-ion battery manufacturers and researchers. The materials consist of Polymer film , that are either Polypropylene (PP) or Polyethylene (PE) based. contain micro and nano pores to provide excellent ion transportation capabilities within the li-ion battery.

Also Ceramic-coated variety for enhanced thermal deformation resistance and mechanical strength.

Specification

|

No.

|

Test Term

|

|

Unit

|

Inspection value

|

|

|

1

|

Thickness

|

|

micron

|

20.0±2.0

|

|

|

2

|

Surface density

|

|

g/㎡

|

17.0±2.0

|

|

|

3

|

Ceramic layer Surface density

|

|

g/㎡

|

8.0±1.5

|

|

|

4

|

Gas permeability

|

|

Sec/100ml

|

250±40

|

|

|

5

|

Gas permeability increment

|

|

%

|

≤15%

|

|

|

6

|

Puncturing Strength

|

|

gf

|

≥580

|

|

|

7

|

120℃ *1h shrinking percentage

|

MD

|

%

|

≤2.0

|

|

|

8

|

|

TD

|

%

|

≤1.5

|

|

|

9

|

Tensile strength

|

MD

|

Mpa

|

≥150

|

|

|

10

|

|

TD

|

Mpa

|

≥135

|

|

|

11

|

Tensile

Elongation |

MD

|

%

|

≥50

|

|

|

12

|

|

TD

|

%

|

≥50

|

|

|

13

|

Film close temperature

|

|

℃

|

≤135

|

|

|

14

|

Width

|

|

mm

|

|

|

|

15

|

Length

|

|

m

|

|

|

|

16

|

Peel strength

|

|

N/m

|

≥40

|

|

|

17

|

Static electricity

|

|

KV

|

≤2.0

|

|

|

18

|

Water content

|

|

ppm

|

≤1200

|

|

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Recommend Products

Hot Searches