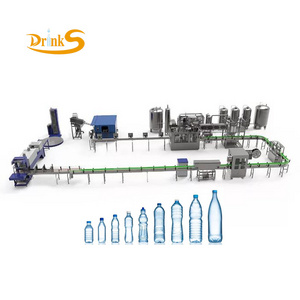

2. The most advanced technology from Japan and Germany is employed in the design. The gravity fixed liquid surface filling is used.The filling is fast, the amount of liquid is accurately controlled and the dropping and leakage are avoided.

3. Spring cramps are used in the bottle washing process. The empty bottles can be turned over 180~ along the conveying rail. There are two times of internal and external washing, the efficiency of bottle washing is high.

5. The whole machine is controlled by PLC with touch-screen as the human-machine interface. The amount of the drinks in the storage tank can be controlled automatically. The filling and capping will be stopped automatically when there is no bottle. When bottles are cramped wrongly or when caps are not available, the machine can be stopped automatically.

6. The frequency changing technology is used to adjust the operation speed sleeplessly. The production capacity can be displayed digitally and can be adjusted conveniently.