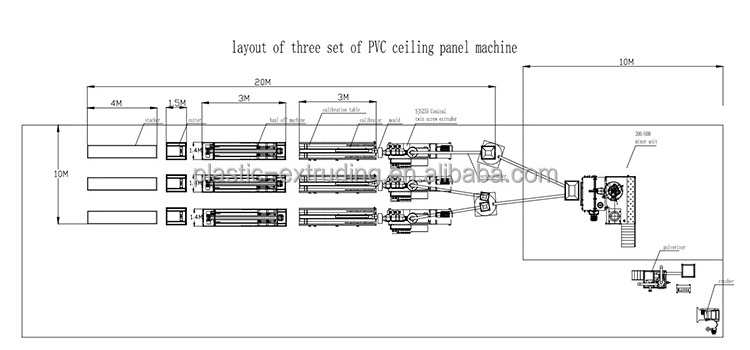

Raw material → screw feeder → mixing → feeder → double screw extruder → vacuum calibration table → haul-off unit → cutting machine

→ stacker

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Horserider

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

3600*1100*2100mm

-

Power (kW):

-

37

-

Weight:

-

4200 KG

-

Usage:

-

Production of PVC plastic celling

-

Motor brand::

-

Siemens Beide

-

Screw&barrel:

-

38CrMoAlA Alloy Screw

-

Contactor:

-

Siemens or Schneder

-

Temperature controller:

-

RKC or OMRON

-

Main inverter brand:

-

Siemens or ABB

-

Keywords:

-

Conical twin screw celling panel extruder production line

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

30:1

-

Screw Speed (rpm):

-

36 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Horserider

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

3600*1100*2100mm

-

Power (kW):

-

37

-

Weight:

-

4200 KG

-

Usage:

-

Production of PVC plastic celling

-

Motor brand::

-

Siemens Beide

-

Screw&barrel:

-

38CrMoAlA Alloy Screw

-

Contactor:

-

Siemens or Schneder

-

Temperature controller:

-

RKC or OMRON

-

Main inverter brand:

-

Siemens or ABB

-

Keywords:

-

Conical twin screw celling panel extruder production line

Product Description

PVC ceiling panel production line/

wall panel machine/

wood plastic ceiling machine/

PVC profile making machine

Description of PVC ceiling wall panel production line:

PVC ceiling wall panel production line is mainly used to produce PVC ceiling, PVC wall panel with width of 200mm,250mm,300mm with different section shape and height. The surface of PVC ceiling can be treated by double color printing and coated with glossy oil, or by heat transfer printing, or by lamination, which can make marble, wooden design on the surface of products.

Situation of the PVC ceiling wall panel production line:

a. Final product output: 3-4m/min, 180-240meter/hour

b. Workshop dimension: 23m (Length)×5m(width) × 4m(Height)

c. Workshop Temperature: ≤40℃

d. Cooling water temperature: <15℃ Water pressure≥0.3Mpa Water consumption: 30m3/h

e. Airpressure: > 0.6Mpa, Air consumption:0.5m3/min

f. Manpower: 3-4 people

g. Total power: 220kw When machine working stable,the power consumption < 150kw/h

h.Power Voltage: 415V/3 phase /50HZ(depend on customer’s request)

b. Workshop dimension: 23m (Length)×5m(width) × 4m(Height)

c. Workshop Temperature: ≤40℃

d. Cooling water temperature: <15℃ Water pressure≥0.3Mpa Water consumption: 30m3/h

e. Airpressure: > 0.6Mpa, Air consumption:0.5m3/min

f. Manpower: 3-4 people

g. Total power: 220kw When machine working stable,the power consumption < 150kw/h

h.Power Voltage: 415V/3 phase /50HZ(depend on customer’s request)

Features:

1.The equipment adapts to various formulations, the ratio of calcium can be increased up to 50%-250%, while the required accessories can be reduced by 30%.

2. The ceiling that the extruder products has an exquisite appearance and uniform plasticization.

3. Laser tracking eliminates problems of the extrusion flow rate, which is helpful to achieve automation of the entire extrusion process.

4 The PVC ceiling extrusion machine has auto-alarm functions in case of emergency, through the use of PID controller.

Main Advantages of this making machine:

1. Speed controlled by inverter, saving power and easy to adjust speed.

2. Extruder temperature controlled by Omron intelligent controller, temperature fluctuation is self adjusting.

3. Low power consumption: power consumption of total production line can low to only 25kw/hour.

The working process of PVC ceiling machine:

Specification

|

Model

|

YFK-250

|

YFK-300

|

YFK-400

|

YFK-600

|

|

Main motor

|

18.5kW

|

30kW

|

37kW

|

55kW

|

|

Extruder

|

SJSZ48/118

|

SJSZ55/110

|

SJSZ65/132

|

SJSZ80/156

|

|

Capacity

|

80-120kg/h

|

100-150kg/h

|

150-250kg/h

|

250-350kg/h

|

Details Images

Production line including:

1.Auto loader for raw material ---1set

2.Extruder---1set

3.Die mould---1set

4.Vacuum cooling table---1set

5.Hot stamping and laminating machine--1set

6.Haul off machine---1set

7.Cutter---1set

8.Stacker---1set

9.Auxilary equitment (mixer, crusher, pulverizer, color printer.etc )

1.Auto loader for raw material ---1set

2.Extruder---1set

3.Die mould---1set

4.Vacuum cooling table---1set

5.Hot stamping and laminating machine--1set

6.Haul off machine---1set

7.Cutter---1set

8.Stacker---1set

9.Auxilary equitment (mixer, crusher, pulverizer, color printer.etc )

SJSZ conical twin screw extruder

﹡Screw, barrel design and manufacturing absorb European advanced technology

﹡Screw and barrel material 38CrMoAlA,nitriding treated

﹡adopt original famous electric components with high steady running quality.

﹡Screw and barrel material 38CrMoAlA,nitriding treated

﹡adopt original famous electric components with high steady running quality.

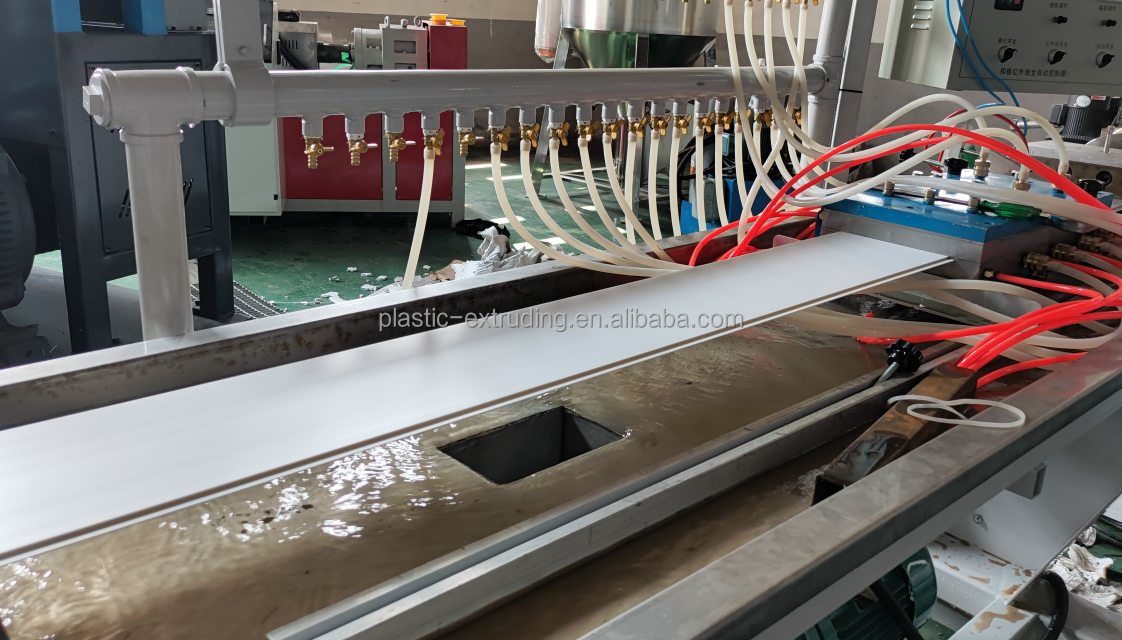

Infrared rectifier

the extruder with Infrared rectifier, so that the panel come out straightly:

Mould according to the drawing

1.

Precision machining, end products surface smooth, section size accuracy

2.Material: 3Cr17 and heat treatment

3.Heater: Superior quality casting aluminum heater

Vacuum calibration and cooling table:

Features:

Compact structure, beautiful appearance, easy to operation and maintain.

Adopt superior quality vacuum & water pump, electric components to make sure durable continuous working.

Compact structure, beautiful appearance, easy to operation and maintain.

Adopt superior quality vacuum & water pump, electric components to make sure durable continuous working.

Hauling off machine

Frequency conversion speed adjusting, pneumatic clamp and release

Online hot stamping &laminating machine two in one for PVC ceiling panel:

Main application: Used to hot stamp printing the color pattern on PVC ceiling board

Dust free cutter

Adopts famous electromagnetism valve, dustproof electric cabinet to keep electric system away from cutting dust and make machine working reliable and no-break.

this type blades can be used to PVC ceiling panel and wall panel

Machine Show

This is PVC ceiling panel and wall panel production line in our workshop,

we sold many lines to India, Pakistan, Negiria, and other countries, in which the PVC ceiling panel is very popular

|

product

|

PVC ceiling panel, PVC panel, PVC wall panel

|

|

|

||

|

|

Proof

|

Light in weight and easy installation

|

|

||

|

|

Unit price

|

US1.50~US4.00

|

|

||

|

|

Caco3 Ratio

|

30-200%

|

|

||

|

|

Width

|

10cm/16cm/18cm/20cm/25cm/30cm/60cm

|

|

||

|

|

Thickness

|

6mm/7mm/7.5mm/8mm/9mm/10mm/11mm/12mm

|

|

||

|

|

Surface

|

Printing, hot-stamping, pearlite printing, peritoneal, normal glossy, high glossy

|

|

||

|

|

(1) High shrink surface, smooth without gap when concatenated

|

|

|

||

|

|

(2) Fireproof, moisture-proof, mould-proof, waterproof, soundproof,

sound-absorbing, light in weight and easy installation

|

|

|

||

|

|

(3) For ceiling and wall decoration

|

|

|

||

|

|

(4) The variety of colors and patterns

|

|

|

||

Hot Searches