- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

HD2023102602

-

Application:

-

Industrial Heating Parts

-

After-sales Service Provided:

-

Video Technical Support

-

Voltage:

-

220-380v

-

Function:

-

Fast Heating

-

Usage:

-

High Temperature Electric Heating

-

Insulation material:

-

Fiberglass Reinforced Silicone Rubber

-

Product name:

-

Customized Heating Elements

-

Size:

-

Cuztomized

-

Wattage:

-

25w/50w/60w/75w/100w/150w/200w

-

Feature:

-

High Power

Quick Details

-

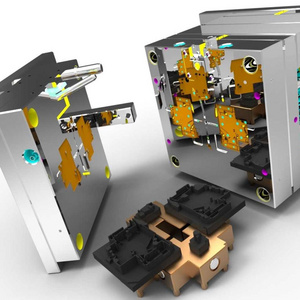

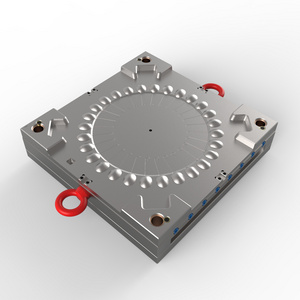

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Zhejiang

-

Brand Name:

-

HANDLING

-

Model Number:

-

HD2023102602

-

Application:

-

Industrial Heating Parts

-

After-sales Service Provided:

-

Video Technical Support

-

Voltage:

-

220-380v

-

Function:

-

Fast Heating

-

Usage:

-

High Temperature Electric Heating

-

Insulation material:

-

Fiberglass Reinforced Silicone Rubber

-

Product name:

-

Customized Heating Elements

-

Size:

-

Cuztomized

-

Wattage:

-

25w/50w/60w/75w/100w/150w/200w

-

Feature:

-

High Power

|

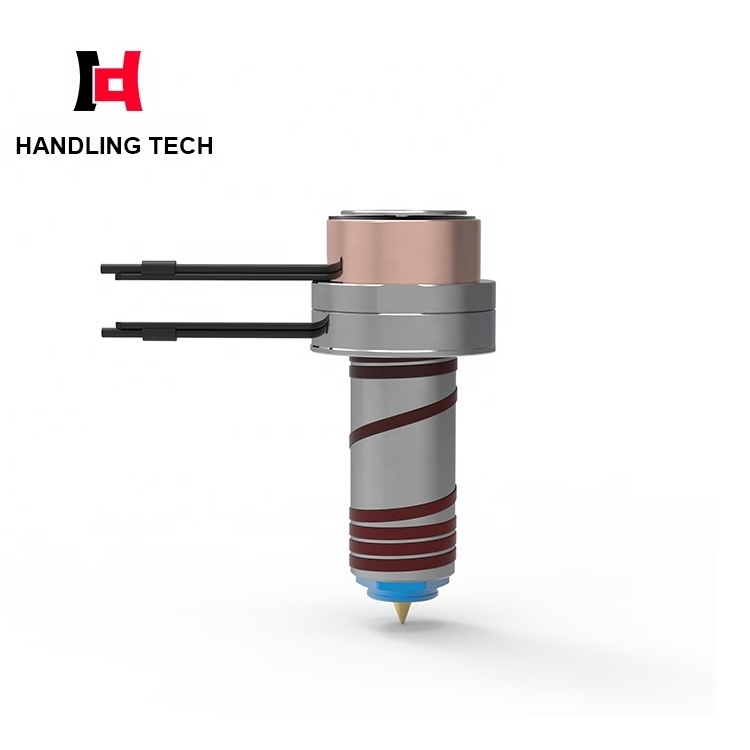

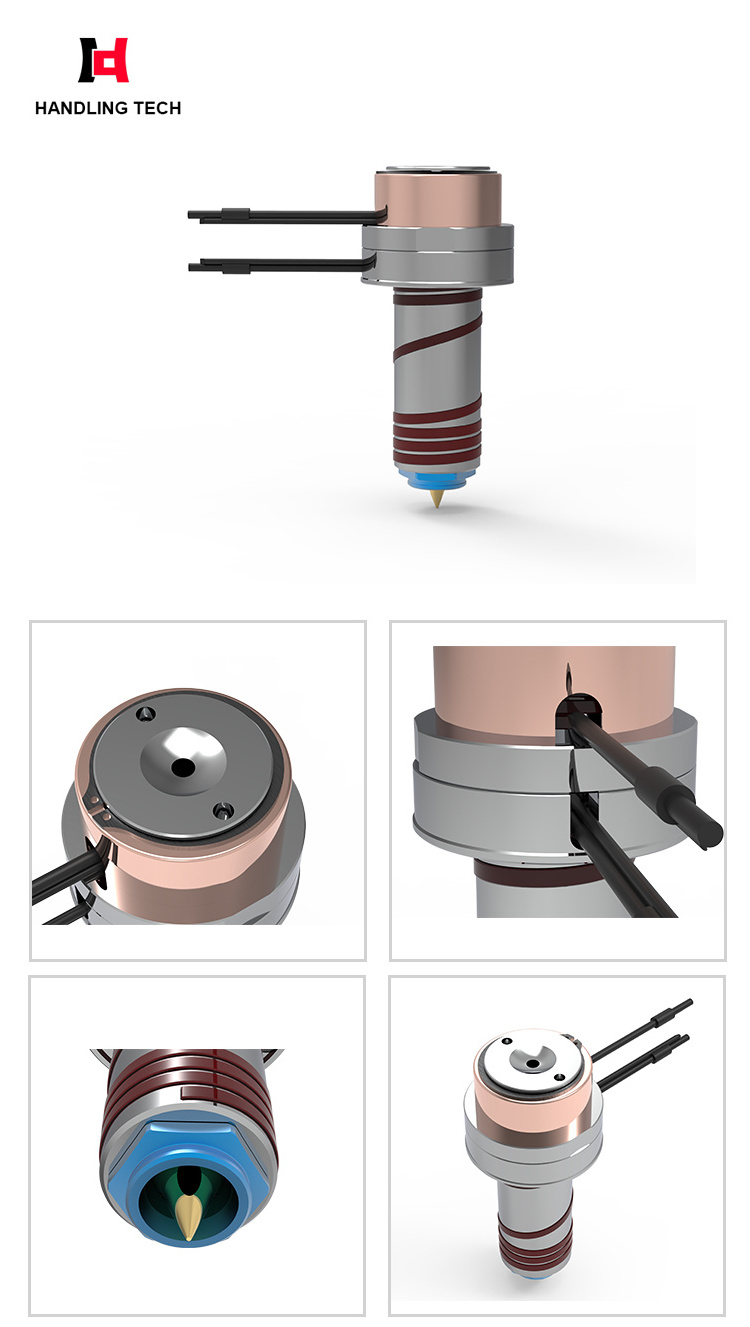

Product name: |

hot runner single ozzle |

|

After service: |

guarantee |

|

Shaping mode: |

Plastic injection mold |

|

Application: |

hot runner system |

|

Change color: |

depend on customer needs |

|

Product material: |

Metal |

|

Advantage: |

HANDLING standard hot nozzle,

Two sections of heating, more accurate temperature control,not easy to appear cold material, Like some high temperature materials, it must be heated in 2 sections.Our current standards have been changed to two-section heatingAlmost all materials can be produced in a single nozzle, and are related to the nozzle type. The single nozzle has a small amount of glue, which is not suitable for a particularly large product. Pin-point gate are not suitable for color change, When the pin-point gate is made of white or transparent thin-walled parts, it is easy to appear Mercedes-Benz line, or it is easy become yellowing or blackening |

Shanghai Handling Hot Runner Technology Co., Ltd. is a subsidiary of handling Enterprise Group. Our company is a private high-tech enterprise .. And specialized in hot runner system R&D, production, sales and service. Our company has a number of nationally recognized invention patents every year Located at No. 365, Lianyang Road, Songjiang Economic an d Development Zone, HANDLING owns over 3500 square meters of standard factory and modern office buildings. The factory area has a beautifu l and comfortable working environment. The company recruit professional and high technical design team from the domestic and international enterprise. We provide you with complete injection molding solutions, high-quality products and outstanding service, continuous pursuit of innovation, and leading the industry's cutting-edge technologies.

Based on many years of experience in the plastics industry, we not only provide standard and general-purpose products, but also can customize special application products and solutions according to customer requirements. We have extensive experience in the application of high-performance engineering plastics and precision injection molded parts. For automotive, electrical, cosmetic packag, medical packaging, daily goods packing industry etc., and can provide customers with free product simulation analysis. The company has established a cop

peration relationship with China's top injection molding laboratory and the British Blue Research Laboratory of Beijing University of Chemical Technology. The Indigo Research Laboratory has provid- ed technical support for Yandian and has achieved a number of research and development projects that have been applied.

HANDLING established a Guangdong branch in 2016: Dongguan HANDLING Injection Molding Technology Co., Ltd., and estab lish Japan HAND LING HOTRUNNER TECH CO.,LTD in 2018 . . It has successively set up offices in Ningbo, Yantai, Kunshan, Chongqing, Suzhou, Hefei, Singapore, Malaysia , Thailand, etc. . The company continuously explore s and developing China's own brand and committed to the development of the Chinese molding industry, and made contributions to the popularity of hot runner technology in China.

HANDLING Company sincerely thanks all users for their strong support, and we will work together with you to go to a glorious tomorrow!

1. We can offer hot runner design scheme for you after you make sure the order.

2. We can offer mold flow analysis report for you, if you need.

3. We can offer samples for your test about some small accessories, but the delivery fee we can ’ t afford.

4. Change fittings for free during warranty period.

5. we will report for you the production process every 5 days. If you need.

Q:How do you control your production quality?

A:We have an independent QC teams do sample inspection, part inspection during production and 100% final inspection before shipment.

Q:Are you trading company or manufacturer.

A: We are manufacturer

Q:How can I get the quotation?

A: Please send us 2D/3D mold design drawing. We will according that make quotation for you soon.

Q:How do you ship the goods and how long does it take arrive?

A:We usually ship by DHL, UPS, FEDEX OR TNT. It usually takes 3-5 days to arrive. Airline and sea also optional.

Q:What ’ s your terms of payment?

A: within 1000 USD, 100 TT in advance. Over 1000USD 30% TT in advance, the balance before shipping.

Q:How long is your delivery time?

A:Generally it is 3-8 days if the goods are in stock. Or it is 10-15 days for non-standard goods. It is according to quantity.

If you have other question, Pls feel free to contact us as the following information.