- Product Details

- {{item.text}}

Quick Details

-

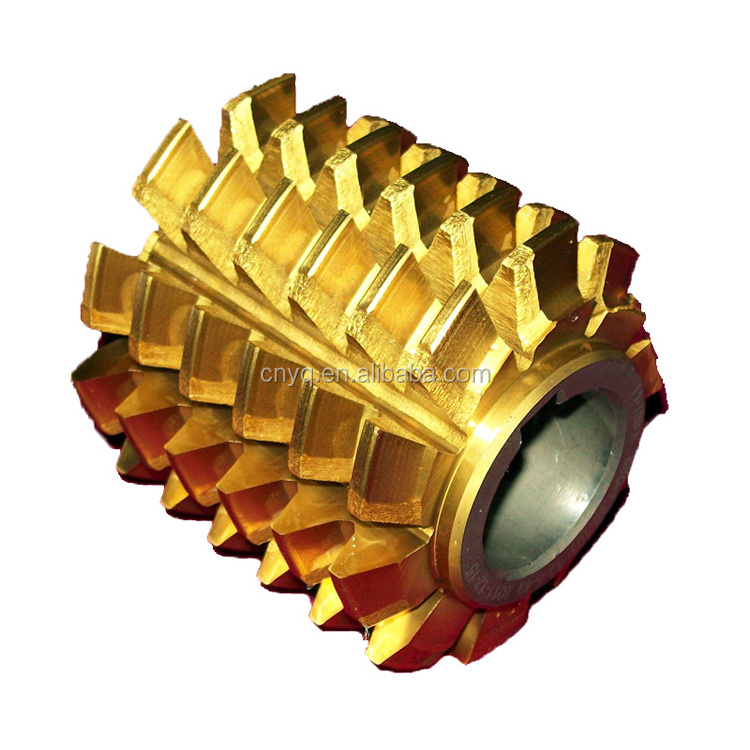

Module:

-

m0.5~m12

-

Place of Origin:

-

Chongqing, China

-

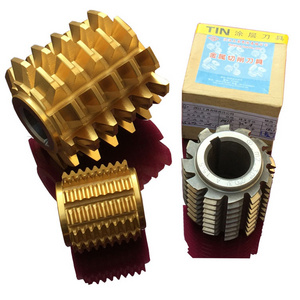

Coating:

-

TIN/TIALN

-

Pressure Angle:

-

14.5/20/30 degree

-

Mateiral:

-

M2/M35

-

Machine Type:

-

Gear Hobbing Machine

-

Standard:

-

DIN3968/DIN3972

-

Accuracy:

-

AA, A

-

No. of start:

-

Single, double

Quick Details

-

Type:

-

gear cutting tool

-

Material:

-

HSS

-

Use:

-

Gear Hob

-

Module:

-

m0.5~m12

-

Place of Origin:

-

Chongqing, China

-

Coating:

-

TIN/TIALN

-

Pressure Angle:

-

14.5/20/30 degree

-

Mateiral:

-

M2/M35

-

Machine Type:

-

Gear Hobbing Machine

-

Standard:

-

DIN3968/DIN3972

-

Accuracy:

-

AA, A

-

No. of start:

-

Single, double

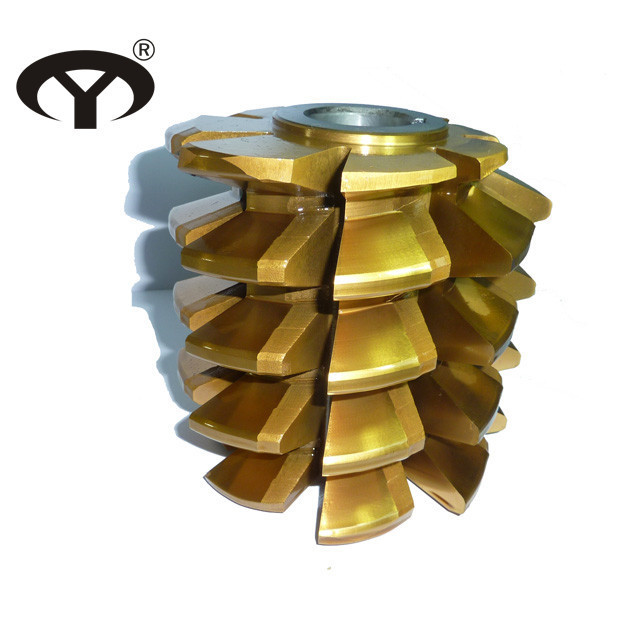

HSS DIN3968 M2/M35 Module spur gear hob cutter with PA20

- pressure angle α = 20°

- reference profile II according to DIN 3978

- relief-ground accuracy class "A" acc. to DIN 3968

- single start, right-hand with keyway slot according to DIN 138

- HSS-E (EMo5Co5)

R GEARS ACCORDING TO DIN 8002B

|

Module |

D |

d |

L |

l |

z |

|

mm |

|||||

|

1 |

50 |

22 |

31 |

3 |

14 |

|

1,25 |

50 |

22 |

31 |

3 |

14 |

|

1,5 |

56 |

22 |

38 |

3 |

12 |

|

1,75 |

56 |

22 |

38 |

3 |

12 |

|

2 |

63 |

27 |

46 |

3 |

12 |

|

2,25 |

70 |

27 |

56 |

3 |

12 |

|

2,5 |

70 |

27 |

56 |

3 |

12 |

|

2,75 |

70 |

27 |

56 |

3 |

12 |

|

3 |

80 |

32 |

69 |

3 |

12 |

|

3,25 |

80 |

32 |

69 |

3 |

12 |

|

3,5 |

80 |

32 |

69 |

3 |

12 |

|

3,75 |

90 |

32 |

78 |

4 |

12 |

|

4 |

90 |

32 |

78 |

4 |

12 |

|

4,5 |

90 |

32 |

78 |

4 |

10 |

|

5 |

100 |

32 |

88 |

4 |

10 |

|

5,5 |

100 |

32 |

88 |

4 |

10 |

|

6 |

115 |

40 |

108 |

4 |

10 |

|

6,5 |

115 |

40 |

108 |

4 |

10 |

|

7 |

115 |

40 |

108 |

4 |

10 |

|

8 |

125 |

40 |

138 |

4 |

10 |

|

9 |

125 |

40 |

138 |

4 |

10 |

|

10 |

140 |

40 |

170 |

5 |

10 |

|

12 |

170 |

50 |

200 |

5 |

9 |

|

14 |

190 |

50 |

224 |

5 |

9 |

|

16 |

210 |

60 |

250 |

5 |

9 |

|

18 |

230 |

60 |

270 |

5 |

9 |

|

20 |

250 |

60 |

296 |

5 |

9 |

Hob cutter series : gear hob , pre-shaving gear hob, pre-grind gear hob, involute spline hob, parallel side spline hob, ground sprocket hob , and timing pulley hob.

Production process of HSS M2/M35 module spur gear hob cutter with TIN :

Material Introduction :

A. W6Mo5Cr4V2 (GB) M2( ASTM), S6-5-2(DIN), SKH51(JIS)

chemical composition:C 0.85, Si 0.38, Mn 0.35, P≤0.030, S≤0.030, Cr 4.10, W 6.00, Mo 4.80 V 1.85

main application:It is widely used for making all kinds of cutters and durability cold-work die

B. W6Mo5Cr4V2Co5 (GB), M35( ASTM), 1.3243(DIN), SKH55(JIS)

chemical composition: C 0.93, Si 0.38, Mn 0.35, P≤0.030, S≤0.030, Cr 4.10, W 6.30, Mo 4.80 V 1.85, Co 5.00

main application:It is often used for making blades with high-speed and great cutting difficulty as it’s good abrasive resistance

W6Mo5Cr4V2(M2),W9Mo3Cr4V(W9),W18Cr4V(W18),W6Mo5Cr4V2Al(M2Al),W6Mo5Cr4V2Co5(M35),W2Mo9Cr4VCo8(M42),W4Mo3Cr4VSi(4341),W4Mo2Cr4VSi(4241)

- reference profile II according to DIN 3978

- relief-ground accuracy class "A" acc. to DIN 3968

- single start, right-hand with keyway slot according to DIN 138

- HSS-E (EMo5Co5)