- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

1 kg

-

Marketing Type:

-

New Product 2022

-

Application:

-

Make Animal Feed

-

Product name:

-

Pellet Mill Roller

-

Name:

-

Pellet Mill Roller

Quick Details

-

Max. Capacity:

-

600 kg/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Des Champs

-

Weight:

-

1 kg

-

Marketing Type:

-

New Product 2022

-

Application:

-

Make Animal Feed

-

Product name:

-

Pellet Mill Roller

-

Name:

-

Pellet Mill Roller

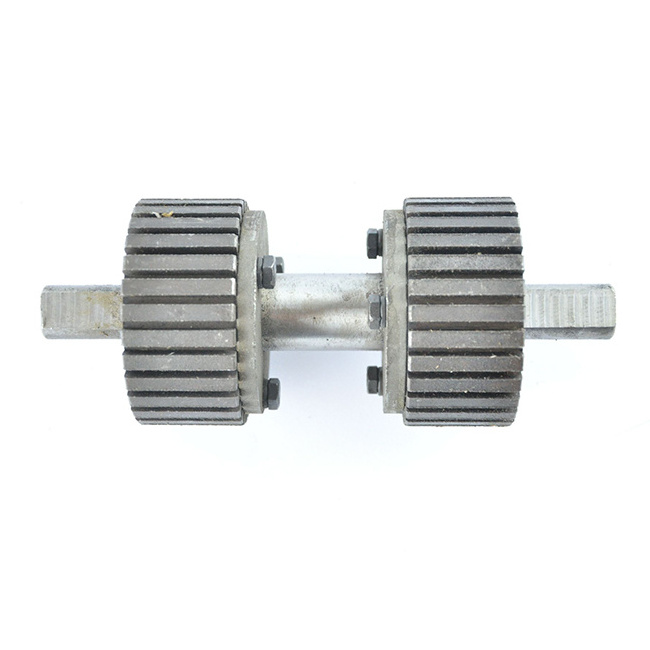

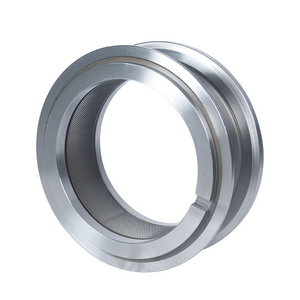

Pellet Mill Roller

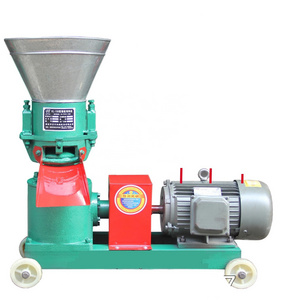

There are components that are part of the pelletizing machine / granulator that have the role of pressing the raw material on the die, thus resulting in granules / pellets.

The pressing rollers are steel, being applied heat treatment, thus resulting in a product with long resistance.

The product is of superior quality, made of a resistant material.

Increasing the lifespan of dies and rolls in the technological process of making feed recipes is possible!

Thus it is very important to take into account the following aspects:

After running in, use raw material without silicates / sand, stones or metal bodies. In this sense, for the elimination of metal bodies, it is very beneficial to mount a permanent magnet on the technological flow.

The dies must be ground before they can be put into operation.

The ground material must be as small as possible.

It would be ideal for the diameter of the holes of the mill sieve with hammers to be up to 1.0 mm smaller than the diameter of the holes of the die.

To ensure a correct conditioning of the product before pressing, so as to ensure an optimal temperature and humidity at the entrance to the die.

Make a correct adjustment of the rollers to the die.

To clean the holes of the mold when the granulation line stops for a period longer than 2-3 hours.

This is possible through a mixture of bran, oil (2%) and an abrasive powder (2%). It is ideal that before any production stop, a mixture of corn or oats is introduced in the die.

After running in, use raw material without silicates / sand, stones or metal bodies. In this sense, for the elimination of metal bodies, it is very beneficial to mount a permanent magnet on the technological flow.

The dies must be ground before they can be put into operation.

The ground material must be as small as possible.

It would be ideal for the diameter of the holes of the mill sieve with hammers to be up to 1.0 mm smaller than the diameter of the holes of the die.

To ensure a correct conditioning of the product before pressing, so as to ensure an optimal temperature and humidity at the entrance to the die.

Make a correct adjustment of the rollers to the die.

To clean the holes of the mold when the granulation line stops for a period longer than 2-3 hours.

This is possible through a mixture of bran, oil (2%) and an abrasive powder (2%). It is ideal that before any production stop, a mixture of corn or oats is introduced in the die.

|

Technical Parameters

|

|

|

|

Name

|

Pellet Mill Roller

|

|

|

Condition

|

New

|

|

|

Size

|

120 mm / 150 mm / 200 mm / 250 mm

|

|

|

Capacity (max)

|

600 kg/h

|

|

Hot Searches