In industrial production, industrial robots can replace people to do certain monotonous, frequent and repetitive long-term operations, or operations in dangerous and harsh environments, such as stamping, pressure casting, heat treatment, welding, painting, plastic product forming, In processes such as mechanical processing and simple assembly, as well as in the atomic energy industry and other sectors, complete the handling or process operations of materials harmful to the human body.

- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

1 years

-

Weight (KG):

-

400

-

Function:

-

welding,cutting

-

Number of axis:

-

6 Axis 5axis 4 Axis

-

Payload:

-

6KG

-

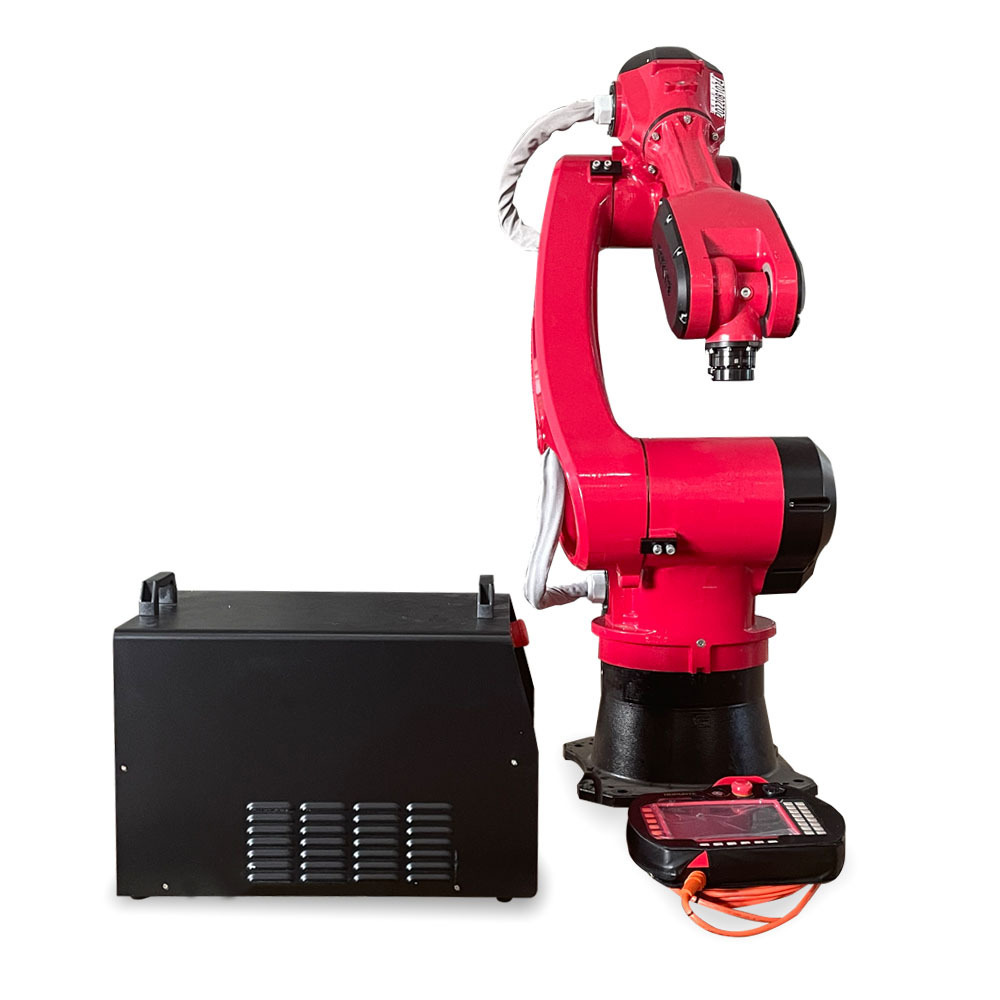

Robot type:

-

6 Axis Articulated Robot

-

Color:

-

Customers' Requirements

-

Level:

-

High Automatic

-

Advantage:

-

Cost Save High Efficiency

-

Display:

-

8 Inch Real Color LCD

-

Structure:

-

Articulated

-

Mounting type:

-

A variety of ways, according to the needs of the plan

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Jiaxin

-

Application:

-

handing,cutting,welding

-

Warranty:

-

1 years

-

Weight (KG):

-

400

-

Function:

-

welding,cutting

-

Number of axis:

-

6 Axis 5axis 4 Axis

-

Payload:

-

6KG

-

Robot type:

-

6 Axis Articulated Robot

-

Color:

-

Customers' Requirements

-

Level:

-

High Automatic

-

Advantage:

-

Cost Save High Efficiency

-

Display:

-

8 Inch Real Color LCD

-

Structure:

-

Articulated

-

Mounting type:

-

A variety of ways, according to the needs of the plan

Product Overview

Industrial Robots

Industrial robots are multi-joint manipulators or multi-degree-of-freedom robots oriented to the industrial field. An industrial robot is a machine device that automatically performs work. It is a machine that realizes various functions by its own power and control capabilities. It can be commanded by humans, and it can also be run in accordance with pre-arranged programs. Modern industrial robots can also act according to the principles and guidelines formulated by artificial intelligence technology.

FEATURES AT A GLANCE

Robot

application

Right elevation

Left elevation

Front elevation

PRODUCT SPECIFICATIONS

|

No

|

Item

|

Data

|

||

|

1

|

Controlled axis

|

6-DOF

|

||

|

2

|

Max payload

|

6kg,8kg,10kg

|

||

|

3

|

Max stroke

|

1.4m,1.8m,2m

|

||

|

4

|

IP Level

|

J1;J2-IP56;J3;J4'J5;J6-IP67

|

||

|

5

|

Installation mode

|

Floor type,ceiling type

|

||

|

6

|

Robot mass

|

200kg

|

||

|

7

|

Applications

|

welding,cutting

|

||

|

Travel range

|

|

|

||

|

1

|

J1 axis S

|

± 160°

|

||

|

2

|

J2 axis L

|

+80° —-145°

|

||

|

3

|

J3 axis U

|

+145°—-75°

|

||

|

4

|

J4 axis R

|

± 190°

|

||

|

5

|

J5 axis B

|

±50°—-210°

|

||

|

6

|

J6 axis T

|

±360°

|

||

|

Travel speed

|

|

|

||

|

1

|

J1 axis S

|

199.5 ˚/s

|

||

|

2

|

J2 axis L

|

159.3˚/s

|

||

|

3

|

J3 axis U

|

199.5˚/s

|

||

|

4

|

J4 axis R

|

392˚/s

|

||

|

5

|

J5 axis B

|

272˚/s

|

||

|

6

|

J6 axis T

|

374˚/s

|

||

|

Electrical cabinet specifications

|

|

|

||

|

1

|

Input power

|

220VAC 50/60hz

|

||

|

2

|

Cooling method

|

Natural cooling

|

||

PRODUCT CONFIGURATION

working principle

The robot control system is the brain of the robot, and it is the main factor that determines the function and performance of the robot.

Industrial robot technology The main task of industrial robot control technology is to control the movement position, posture and trajectory, operation sequence and action time of the industrial robot in the working space. It has the characteristics of simple programming, software menu operation, friendly human-computer interaction interface, online operation prompts and convenient use.

Key technologies include:

(1) Open and modular control system architecture: adopts distributed CPU computer structure, divided into robot controller (RC), motion controller (MC), photoelectric isolation I/O control board, sensor processing board and programming display Teaching box and so on. The robot controller (RC) and the programming teaching box communicate through the serial port/CAN bus. The main computer of the robot controller (RC) completes the robot's motion planning, interpolation and position servo, main control logic, digital I/O, sensor processing and other functions, while the programming teaching box completes the display of information and the input of keys.

(2) Modular and hierarchical controller software system: The software system is built on the open source-based real-time multitasking operating system Linux, and adopts hierarchical and modular structure design to realize the openness of the software system. The entire controller software system is divided into three levels: hardware driver layer, core layer and application layer. The three levels face different functional requirements and correspond to different levels of development. Each level in the system is composed of several modules with opposite functions. These functional modules cooperate with each other to realize the functions provided by the level.

(3) Robot fault diagnosis and safety maintenance technology: Diagnosing robot faults through various information and performing corresponding maintenance are the key technologies to ensure the safety of robots.

Successful Project

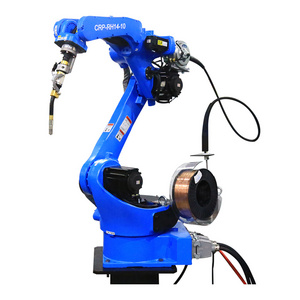

Gantry welding robot

Fixed welding robot

Multiple welding robots cooperate.

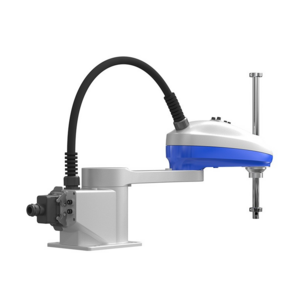

Related machines

FAQ

5Q1:What is the function of this manipulator?

A1:

Welding, cutting, handling.

Q2.:Are you a manufacturer?

A2: Yes, we have our factory in Anhui province.

Q3: How to choose a robot arm?

A3: Step 1: Select traverse stroke, crosswise stroke and vertical stroke according to the tonnage of your injection molding machine.

Step 2: Select a single arm or double arms according to the plates of mold.

Step 3: Select a single stage or telescopic type according to the height of your transporter crane.

Q4: what's your product lead time?

A4: Within 15 days after received payments.

Q5: What is the payment way?

A5: T/T, Paypal, Western Union, L/C

A2: Yes, we have our factory in Anhui province.

Q3: How to choose a robot arm?

A3: Step 1: Select traverse stroke, crosswise stroke and vertical stroke according to the tonnage of your injection molding machine.

Step 2: Select a single arm or double arms according to the plates of mold.

Step 3: Select a single stage or telescopic type according to the height of your transporter crane.

Q4: what's your product lead time?

A4: Within 15 days after received payments.

Q5: What is the payment way?

A5: T/T, Paypal, Western Union, L/C

Hot Searches