- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.4-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZTRFM

-

Voltage:

-

380V,50HZ,3PH

-

Dimension(L*W*H):

-

14600*700*1600mm

-

Weight:

-

5500 kg

-

Feeding width:

-

Other

-

Name:

-

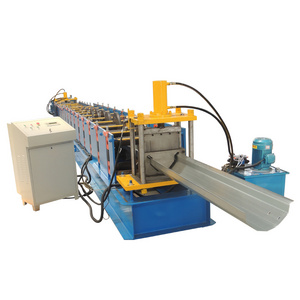

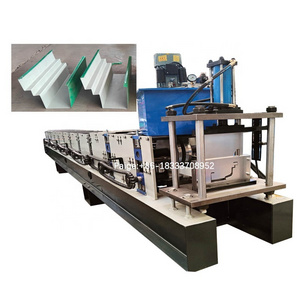

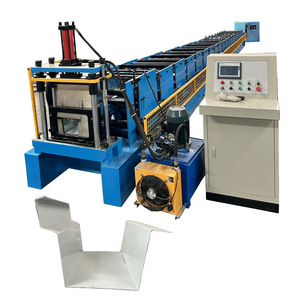

Rain Gutter Making Machine Roll Forming Machine

-

Raw material:

-

PPGI,GI,SS,Aluminium

-

Thickness:

-

0.4-0.8 mm

-

Control system:

-

Touch Screen

-

Speed:

-

0~20 M/min

-

Usage:

-

drain water

-

Color:

-

Customer's Requirement

-

After-sell service:

-

Life Time Service

-

Cutting system:

-

Hydraulic Cutting,no burr no waste

-

Certification:

-

ISO,CE

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel/Galvanized steel/Aluminium-SS

-

Production Capacity:

-

0-20m/min

-

Rolling thinckness:

-

0.4-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZTRFM

-

Voltage:

-

380V,50HZ,3PH

-

Dimension(L*W*H):

-

14600*700*1600mm

-

Weight:

-

5500 kg

-

Feeding width:

-

Other

-

Name:

-

Rain Gutter Making Machine Roll Forming Machine

-

Raw material:

-

PPGI,GI,SS,Aluminium

-

Thickness:

-

0.4-0.8 mm

-

Control system:

-

Touch Screen

-

Speed:

-

0~20 M/min

-

Usage:

-

drain water

-

Color:

-

Customer's Requirement

-

After-sell service:

-

Life Time Service

-

Cutting system:

-

Hydraulic Cutting,no burr no waste

-

Certification:

-

ISO,CE

Product Description

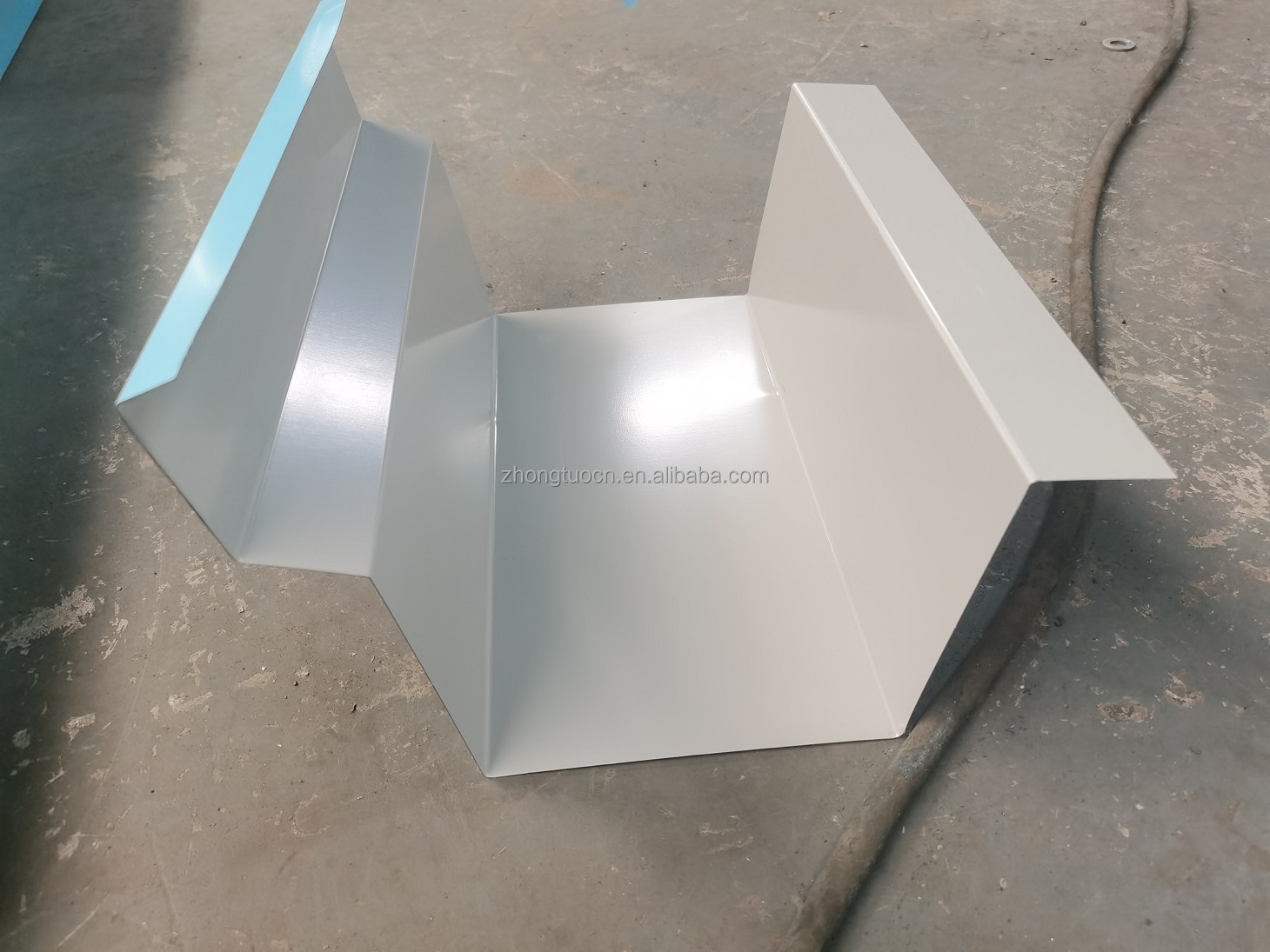

High Quality Metal Rain Gutter Making Machine 5 inch 6 inch K Style Gutter Machine

High Quality Metal Rain Gutter Making Machine 5 inch 6 inch K Style Gutter Machine

:

1.Manual/hydraulic uncoiler

2.Roll former

3.Hydraulic cutting system

4.PLC control system

5.Product receive table

High Quality Metal Rain Gutter Making Machine 5 inch 6 inch K Style Gutter Machine

picture:

|

High Quality Metal Rain Gutter Making Machine 5 inch 6 inch K Style Gutter Machine

|

|

|

|

|

||||

|

1.Formed Material

|

PPGI,GI,AI,GL

|

|

Thickness:0.4-0.8mm

|

|

||||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

|

Manual decoiler(will give you as free)

|

|

||||

|

3.Main body

|

Roller station

|

|

22 rows with a series of vertical rollers

|

|

||||

|

|

Diameter of shaft

|

|

70mm solid shaft

|

|

||||

|

|

Material of rollers

|

|

45# steel, hard chrome plated on the surface

|

|

||||

|

|

Machine body frame

|

|

350 H steel

|

|

||||

|

|

Drive

|

|

Chain transmission

|

|

||||

|

|

Dimension(L*W*H)

|

|

14500*900*1100(customize)

|

|

||||

|

|

Weight

|

|

7T

|

|

||||

|

4.Cutter

|

Automatic

|

|

cr12mov material, no scratches, no deformation

|

|

||||

|

5.Power

|

Motor Power

|

|

7.5 KW

|

|

||||

|

|

Hydraulic system power

|

|

3.5 KW

|

|

||||

|

6.Voltage

|

380V 50Hz 3Phase

|

|

As your requirement

|

|

||||

|

7.Control system

|

Electric Box

|

|

Customized(famous brand)

|

|

||||

|

|

Language

|

|

English(Support multiple languages)

|

|

||||

|

|

PLC

|

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|

||||

|

18.Forming Speed

|

15-20m/min

|

|

The speed is adjustable

|

|

||||

Components of the whole production line:

Part 1:Decoiler/Uncoiler:

Manual or hydraulic for optional

Part 2:Roll forming machine

Roller station:22 stations

Part 3:Control station

Siemens/Delta brand

Part 4:Hydraulic station

With fan cooling

Part 5:Run-out table

3m Length

Part 6:Spare parts

For free

Cooperated brand

Related product

Why Choose Us

Hot Searches