- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±0.1%

-

Voltage:

-

220V/110V, customized

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Cosmati

-

Dimension(L*W*H):

-

L850*W640*H1250(mm)

-

Weight:

-

180 KG

-

Product name:

-

Semi Automatic soft tube filling and sealing machine

-

Keywords:

-

soft tube filling and sealing machine

-

Filling Range:

-

5-200ml (Can be customized)

-

Capacity:

-

12-15 PCS/Min

-

Structure:

-

Vertical

-

Air Pressure:

-

0.5MPa

-

Filling nozzles:

-

1/2/4 can be customized

-

Material:

-

SS316L+304 Stainless Steel

-

Applicable tube height:

-

50-210mm

Quick Details

-

Machinery Capacity:

-

2000BPH, 1000BPH

-

Packaging Material:

-

Wood, Other

-

Filling Material:

-

Other, Water, Oil, Powder

-

Filling Accuracy:

-

±0.1%

-

Voltage:

-

220V/110V, customized

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Cosmati

-

Dimension(L*W*H):

-

L850*W640*H1250(mm)

-

Weight:

-

180 KG

-

Product name:

-

Semi Automatic soft tube filling and sealing machine

-

Keywords:

-

soft tube filling and sealing machine

-

Filling Range:

-

5-200ml (Can be customized)

-

Capacity:

-

12-15 PCS/Min

-

Structure:

-

Vertical

-

Air Pressure:

-

0.5MPa

-

Filling nozzles:

-

1/2/4 can be customized

-

Material:

-

SS316L+304 Stainless Steel

-

Applicable tube height:

-

50-210mm

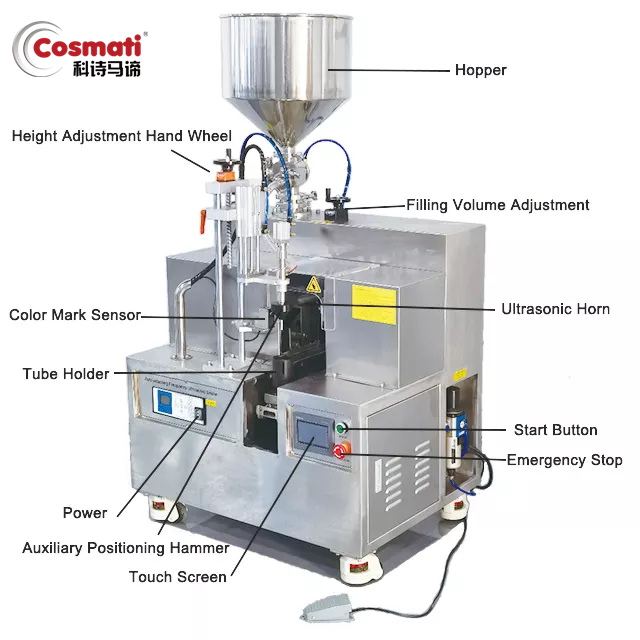

Plastic Soft Tube Filling and Ultrasonic Sealing Machine For Cosmetic Cream Toothpaste Ointment

Products Description

Introduction

*Ultrasonic tube filling and sealing machine is a high-quality, high-performance liquid and paste container filling and sealing packaging machine, which adopts manual tube loading, automatic detection of color code, automatic filling, automatic sealing and automatic tail cutting, using PLC control, touch human-machine interface.

*The operation of this equipment is simple, stable and reliable, which can help enterprises improve production efficiency and reduce labor intensity. It is the first choice equipment for filling and sealing.

Features

1. PLC Touch screen operation, humanized design, simple and intuitive operation.

2. Pneumatic filling control ensures the accuracy of filling.

3. Adopt the structure design of anti-drip and anti-drawing filling nozzle.

4. The material of the whole machine is composed of stainless steel and anodized aluminum alloy.

2. Pneumatic filling control ensures the accuracy of filling.

3. Adopt the structure design of anti-drip and anti-drawing filling nozzle.

4. The material of the whole machine is composed of stainless steel and anodized aluminum alloy.

5. Single head filling, ultrasonic sealing.

No tubes no sealing.

Flow

Manual tube feeding - Tube fixing - Benchmarking - Filling - Sealing - Date printing - Tube tail cutting

Product Paramenters

|

Capacity

|

Dimension(mm)

|

Power supply

|

Sealing diameter

|

Filling accuracy

|

|

12-15 tubes/min.

|

L850*W640*H1150mm

|

110V/220V/380V

|

13-50mm

|

≤±1%

|

|

Filling range

|

Weight

|

Power

|

Sealing height

|

Working pressure

|

|

5-200ml

|

180KG

|

2.6KW

|

50-220mm

|

0.5MPa

|

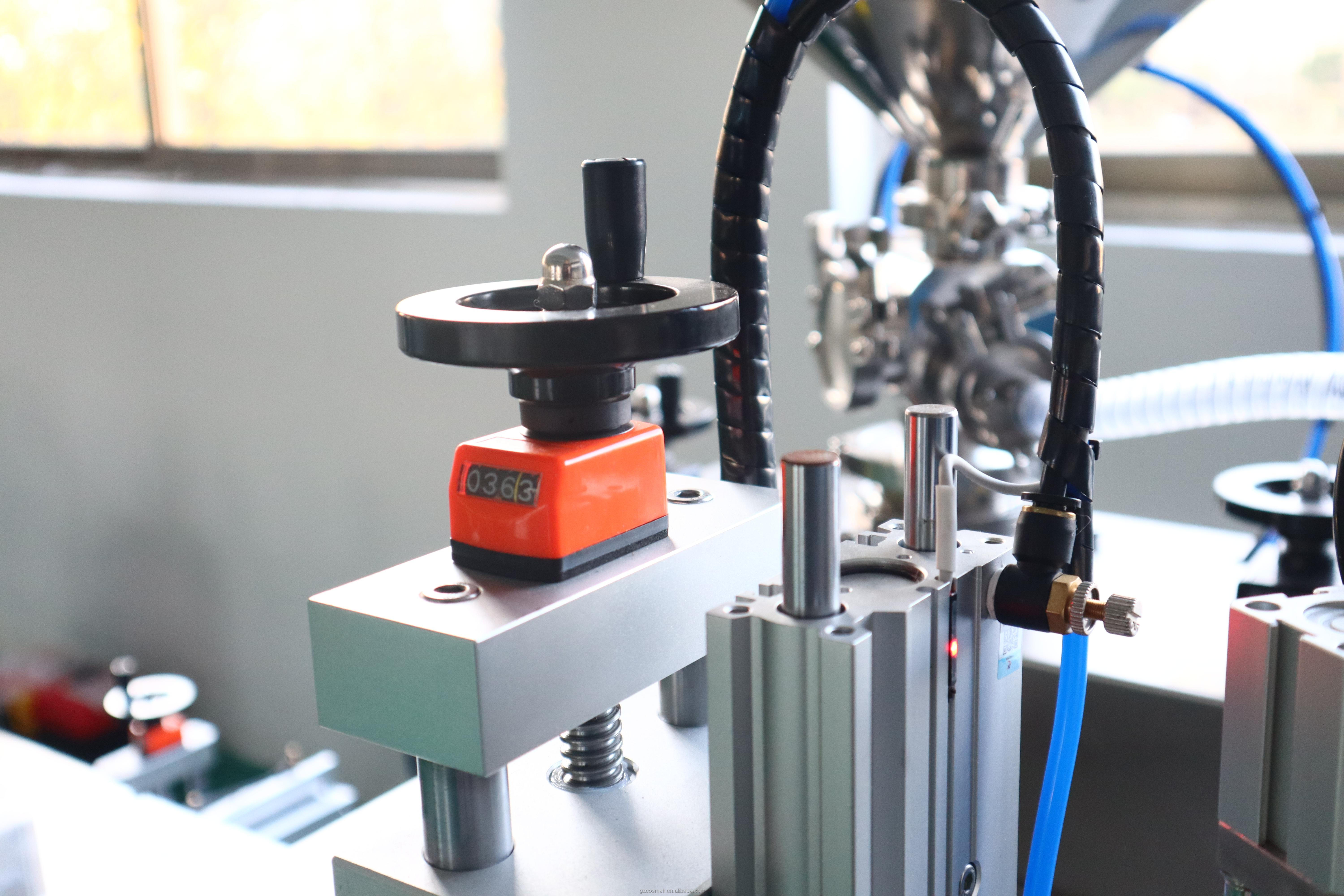

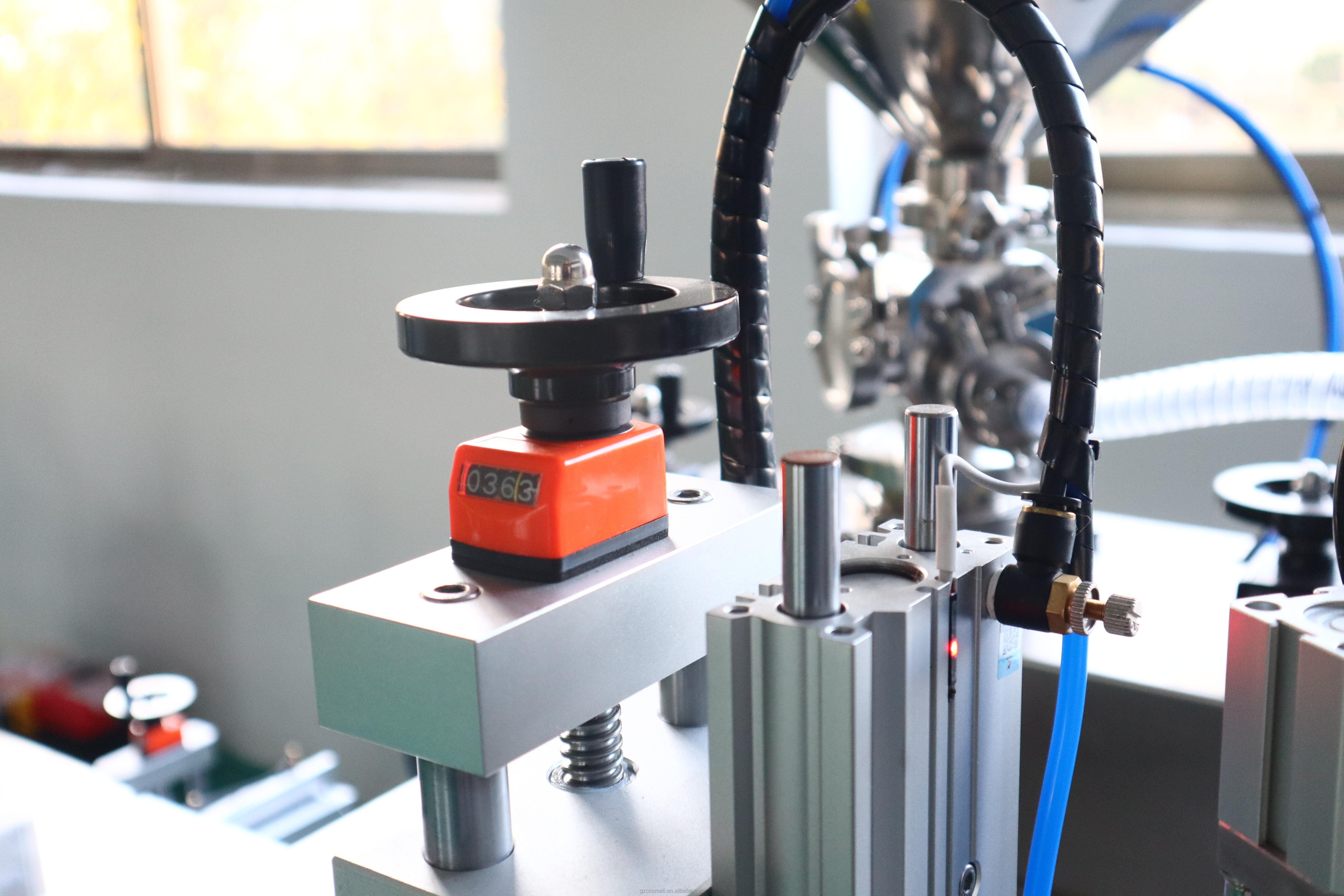

Details Images

Product Shots

Application

Suitable for ointment, toothpaste, facial cleanser, conditioner, shampoo, hand cream, eye cream, hair color cream, shoe polish and other products.

Recommend Products

Hot Searches