Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

LT-8265,LT-8200

-

Curing mechanism:

-

Poly addition

-

Color LT-8265:

-

Green (can be adjusted)

-

Color LT-8200:

-

Brown

-

Color after mixing:

-

Green (can be adjusted)

-

Viscosity (after mixing):

-

50000-100000mpa.s

-

Pot life:

-

30-50 mins

-

Open time:

-

40-60 mins

-

Initial cure time:

-

2 hours

-

Set to light foot traffic:

-

12 hours

-

Recommended working temperature:

-

0℃-30℃

Quick Details

-

Color:

-

green

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

GTT

-

Model Number:

-

LT-8265,LT-8200

-

Curing mechanism:

-

Poly addition

-

Color LT-8265:

-

Green (can be adjusted)

-

Color LT-8200:

-

Brown

-

Color after mixing:

-

Green (can be adjusted)

-

Viscosity (after mixing):

-

50000-100000mpa.s

-

Pot life:

-

30-50 mins

-

Open time:

-

40-60 mins

-

Initial cure time:

-

2 hours

-

Set to light foot traffic:

-

12 hours

-

Recommended working temperature:

-

0℃-30℃

Product Description

Specification

|

Curing mechanism

|

Poly addition

|

|

Color after mixing

|

Color after mixing

|

|

Viscosity (after mixing)

|

50000-100000mpa.s(Brookfield–RVT7/20)

|

|

Pot life

|

30-50 mins

|

|

Open time

|

40-60 mins

|

|

Initial cure time

|

2 hours

|

|

Set to light foot traffic

|

12 hours

|

|

Recommended working temperature

|

0℃-30℃

|

Packing & Delivery

Model:LT- 8265,LT8200 ,Two-component polyurethane adhesive HS.CODE:3506919090

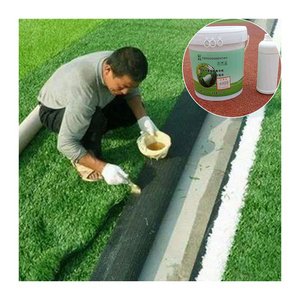

Application

(1) Preparation

Substrates Preparation

According to the synthetic grass usage, substrates must be prepared according to current regulations and standards.

Synthetic Grass Preparation

Unroll and spread out the synthetic grass for several hours before starting installation to allow internal tension caused by the packaging to be reduced.

Adhesive Preparation

Empty barrel for mixing the adhesive: Must be clean and dry.

Mixing tool: Stick for mixing manually or electric mixer.

Electronic scale.

(2) Applying Process

ALT 8265/BLT 8200=9:1 (by weight)

The resin LT 8265 should be mixed thoroughly before its mixing with the hardener LT 8200. Mix the two components fast till the color is uniform, then mix for 1-2 more minutes.

Apply the adhesive with a notched trowel to achieve a fine appearance and effect.

Use up the mixer as soon as possible before its pot life.

(3) Pressing

Bond synthetic grass joint strips and press within adhesive open time, or the adhesion effect will be affected. Increase the

pressure as high as possible with affecting the material forming.

(4) Clean

Recommended Cleaner: dichloromethane, ethyl acetate.

Packaging

Resin: 9kg/barrel

Hardener: 1kg/barrel

The packaging can be adjusted according to customer's requirement.

Storage and Shelf Life

The product remains stable for 12 months (component A), 6 months (component B) if stored in its original sealed container, under

shady and ventilated condition, avoiding direct sunlight and rain.

Recommended storage temperature: 0-30ºC.

Application

(1) Preparation

Substrates Preparation

According to the synthetic grass usage, substrates must be prepared according to current regulations and standards.

Synthetic Grass Preparation

Unroll and spread out the synthetic grass for several hours before starting installation to allow internal tension caused by the packaging to be reduced.

Adhesive Preparation

Empty barrel for mixing the adhesive: Must be clean and dry.

Mixing tool: Stick for mixing manually or electric mixer.

Electronic scale.

(2) Applying Process

ALT 8265/BLT 8200=9:1 (by weight)

The resin LT 8265 should be mixed thoroughly before its mixing with the hardener LT 8200. Mix the two components fast till the color is uniform, then mix for 1-2 more minutes.

Apply the adhesive with a notched trowel to achieve a fine appearance and effect.

Use up the mixer as soon as possible before its pot life.

(3) Pressing

Bond synthetic grass joint strips and press within adhesive open time, or the adhesion effect will be affected. Increase the

pressure as high as possible with affecting the material forming.

(4) Clean

Recommended Cleaner: dichloromethane, ethyl acetate.

Packaging

Resin: 9kg/barrel

Hardener: 1kg/barrel

The packaging can be adjusted according to customer's requirement.

Storage and Shelf Life

The product remains stable for 12 months (component A), 6 months (component B) if stored in its original sealed container, under

shady and ventilated condition, avoiding direct sunlight and rain.

Recommended storage temperature: 0-30ºC.

Hot Searches