- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

New Product 2022

-

Application:

-

Cold Rolling Machine

-

After-sales Service Provided:

-

Online Supports

-

Raw material:

-

SPHC, SS

-

Function:

-

Make Spiral Blade

-

Capacity:

-

1-6 r/min

-

Motor power:

-

29.5KW

-

Model:

-

BB-220

-

Control system:

-

Servo System

-

Voltage:

-

380V 50Hz 3Phase/Customized

-

Product name:

-

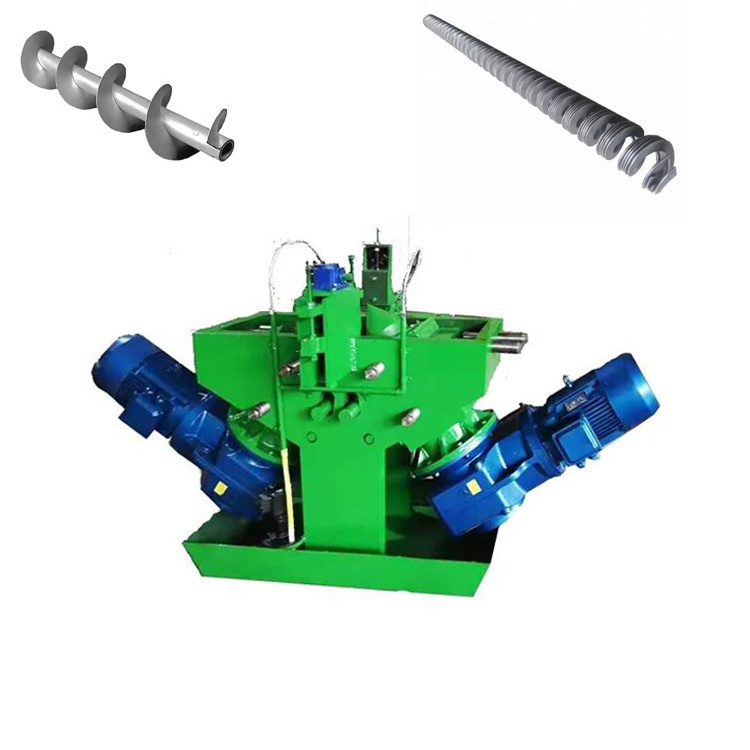

Continuous Helical Spiral Screw Blade Cold Rolling Forming Machine

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

bobo

-

Weight (KG):

-

7200

-

Marketing Type:

-

New Product 2022

-

Application:

-

Cold Rolling Machine

-

After-sales Service Provided:

-

Online Supports

-

Raw material:

-

SPHC, SS

-

Function:

-

Make Spiral Blade

-

Capacity:

-

1-6 r/min

-

Motor power:

-

29.5KW

-

Model:

-

BB-220

-

Control system:

-

Servo System

-

Voltage:

-

380V 50Hz 3Phase/Customized

-

Product name:

-

Continuous Helical Spiral Screw Blade Cold Rolling Forming Machine

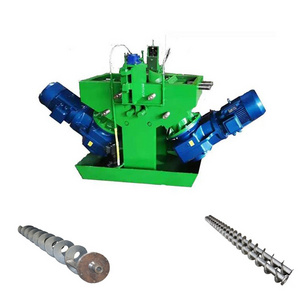

Hydraulic Continuous Helical Spiral Screw Flight Blade

Cold Rolling Forming Machine Spiral Blade

Description

The spiral blade cold rolling mill is a special cold rolling machine for continuous rolling of spiral blades from coiled strip steel. It can roll the required blades of various specifications by adjusting the adjustment parts (roll offset, feeding height, rolling pressure, guide wheel, etc.).

The continuous forming spiral blade cold rolling machine is designed with conical rolls, the strip steel can be cold rolled through the rolls to produce continuous spiral blades, replacing the traditional cold drawing forming process. The machine has the advantages of high production efficiency, saving raw materials, small deviation of pitch size, one time forming, high hardness, smooth surface, continuous without welding seam, etc.

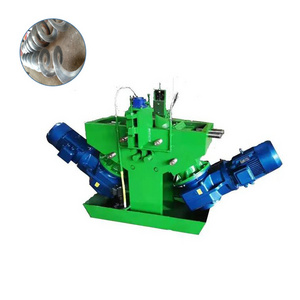

★ Processing Effect Display

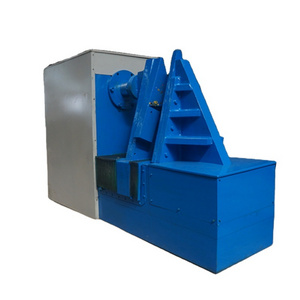

★ Main Parameter

|

NO.

|

Item

|

Parameter

|

|

|

||

|

1

|

Model

|

BB-270

|

BB-350

|

BB-400

|

||

|

2

|

Working mode

|

Mechanical

|

Mechanical

|

Hydraulic

|

||

|

3

|

The thickness of rolled strip

|

2-5mm

|

2-6mm

|

2-8mm

|

||

|

4

|

The width of the strip rolling

|

≤90mm

|

≤130mm

|

≤150mm

|

||

|

5

|

ID

|

25-90mm

|

25-110mm

|

30-110mm

|

||

|

6

|

OD

|

90-270mm

|

90-350mm

|

90-400mm

|

||

|

7

|

Pitch of screw thread

|

80-230mm

|

80-300mm

|

80-350mm

|

||

|

8

|

Rolled speed

|

1-6r/min

|

1-6r/min

|

1-6r/min

|

||

|

9

|

Main motor working speed

|

1440r/min

|

1440r/min

|

980r/min

|

||

|

10

|

Main power

|

26.5kw

|

26.5kw

|

34kw

|

||

|

11

|

Gross weight

|

6T

|

6.7T

|

9T

|

||

Product packaging

Packaging:

Stable wooden package protects machine from strike and damage.

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.

Shipping:

For LCL, we cooperated with reputable logistics team to send machine to sea port speedily and safely.

For FCL, we get the container and do container loading by our skillful workers carefully.

For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like

to have seamless cooperation with your forwarder at your convenience.

Stable wooden package protects machine from strike and damage.

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.

Shipping:

For LCL, we cooperated with reputable logistics team to send machine to sea port speedily and safely.

For FCL, we get the container and do container loading by our skillful workers carefully.

For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like

to have seamless cooperation with your forwarder at your convenience.

Hot Searches