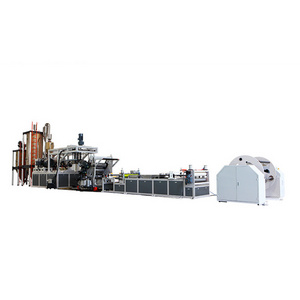

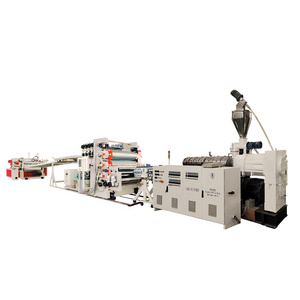

Name: SJZ80/173 Conical twin screw extruder

Technical parameters:

a.Main motor :90kw Siemens Brand.

b.Inverter:ABB

c.Screw barrel: 38CrMoAl, hardness Hv950 or more , high-efficiency and long service life.

d. Vacuum pump : Double station.

Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

50 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ACEMIEN

-

Voltage:

-

380v or customized

-

Dimension(L*W*H):

-

30m*3m*4m

-

Power (kW):

-

200

-

Weight:

-

20000 KG

-

Name:

-

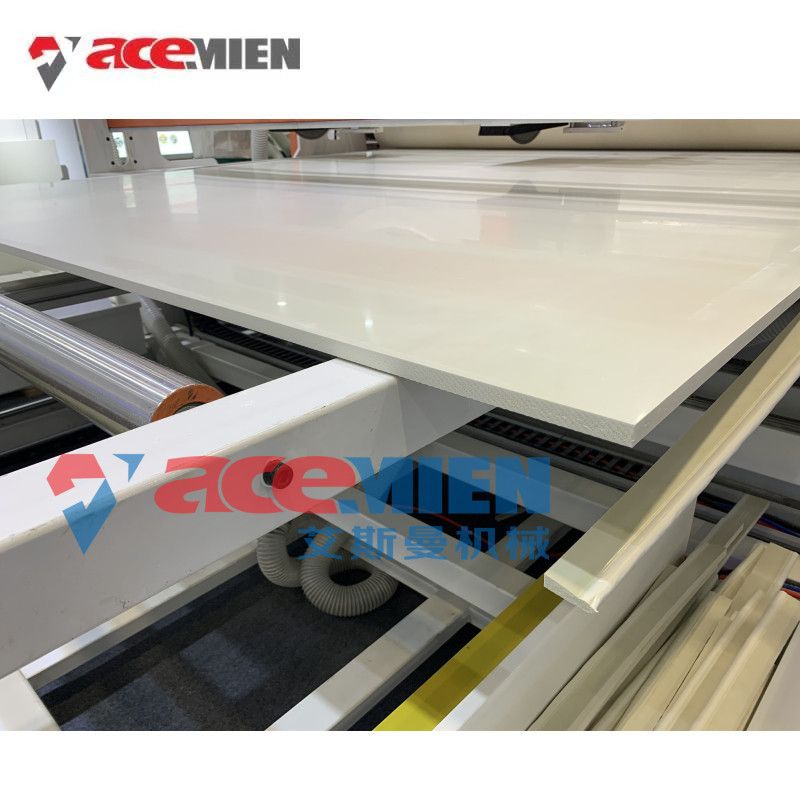

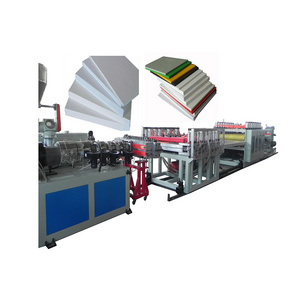

PVC foam board production line

-

Raw material:

-

PVC Powder

-

Usage:

-

Plastic Forming Machine

-

Product Type:

-

PVC Foam Board

-

Processing Type:

-

Exturding Machine

-

Contactor:

-

French Schneider

-

Inverter:

-

ABB Brand

-

Motor:

-

SIEMENS Brand

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

38:1

-

Screw diameter (mm):

-

80 mm

-

Screw Speed (rpm):

-

50 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ACEMIEN

-

Voltage:

-

380v or customized

-

Dimension(L*W*H):

-

30m*3m*4m

-

Power (kW):

-

200

-

Weight:

-

20000 KG

-

Name:

-

PVC foam board production line

-

Raw material:

-

PVC Powder

-

Usage:

-

Plastic Forming Machine

-

Product Type:

-

PVC Foam Board

-

Processing Type:

-

Exturding Machine

-

Contactor:

-

French Schneider

-

Inverter:

-

ABB Brand

-

Motor:

-

SIEMENS Brand

Extrusion System

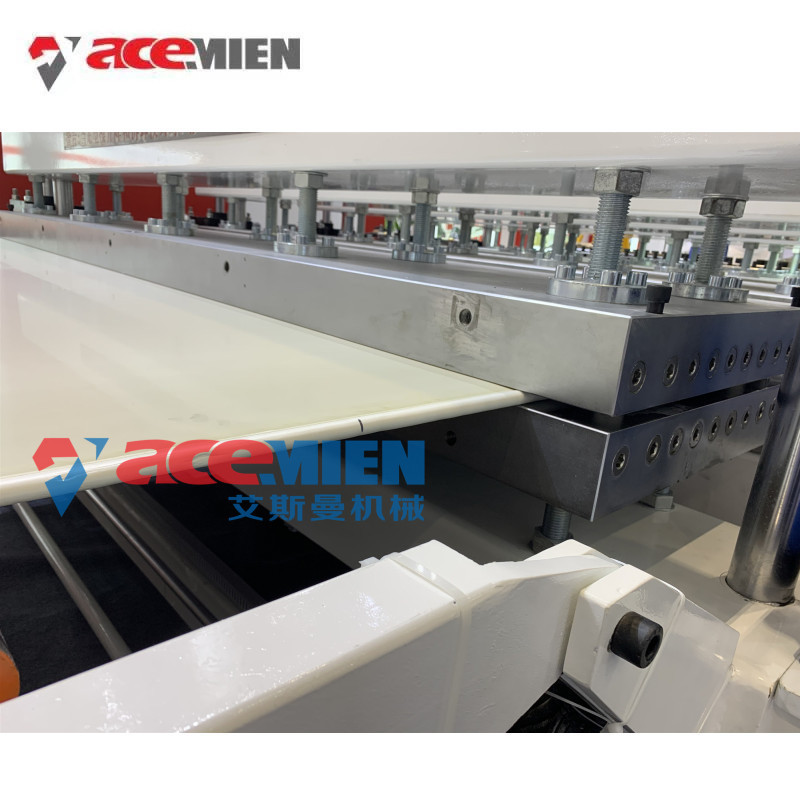

Mould Part

Name: Extrusion and calibration mould

Technical parameters:

a.Unique die structure for hollow products using core molding optimized flow path through computer simulation to ensure uniform and stable flow.

b.Independent air flow control system to quickly balance the airflow in a short time to obtain a stable production .

c.Fine polishing of the cavity , lip and flowing channel.

Haul-off Roller

Name: Haul-off unit

Technical parameters:

a.High quality rubber on the surface.

b.Surface shore hardness 65-70.

c.Roller thicknee is more than 18mm.

d.Increase the diameter of shaft heads and bearings ensure stable operation of thick board.

e.Double-row chain drive,forward and backward roller transmission coefficient is consistent .

Cutter

Name:

Cutter

Technical parameters:

a.Special positioning to ensure cutting accurecy.

b.Special knife structure, safe and stable

c.PLC control system, double dust system.

1. kitchen cabinet, washroom cabinet. Building outdoor wall board, indoor decoration board, partition board in office and house.

2.Partition with hollow design.Architectural decorations and upholstery.

3.Screen printing, flat solvent printing, engraving, billboard and exhibition display.

3.Screen printing, flat solvent printing, engraving, billboard and exhibition display.

|

Machine List

|

|

|

|

|||

|

No.

|

Name

|

Qty.

|

Remark

|

|||

|

1

|

Screw loader for extruder

|

1

|

|

|||

|

2

|

SJZ 80/173 conical twin screw extruder

|

1

|

|

|||

|

3

|

Extrusion mould unit

|

1

|

1220*2440

|

|||

|

4

|

Vacuum calibration Table

|

1

|

|

|||

|

5

|

Cooling bracket

|

1

|

|

|||

|

6

|

Haul off unit

|

1

|

|

|||

|

7

|

Edge cutting device

|

1

|

|

|||

|

8

|

Tracking cutter

|

1

|

|

|||

|

9

|

Automatic shift machine

|

1

|

|

|||

|

10

|

Dust collection device

|

1

|

|

|||

|

11

|

Mould temperature controller

|

1

|

|

|||

|

Auxiliary Machine

|

|

|

|

|||

|

12

|

SRL-Z Series Mixer unit

|

1

|

Capacity : 450-550kg/h

|

|||

|

13

|

Screw loader for Mixer

|

1

|

|

|||

|

14

|

Crusher

|

1

|

Power: 11kw,22kw,30kw

|

|||

|

15

|

Pulverizer

|

1

|

Power: 45kw,55kw,75kw

|

|||