Maximum in-let wire diameter: 2.0mm

Minimum out-let wire diameter: 0.43mm

- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

Hot Product 2021, Hot Product 2021

-

Nominal pressure:

-

250KN

-

Capacity:

-

12-18 boxes/min

-

Slide Strokes Per Minute:

-

100-140 times/min

-

Wire band width:

-

100-130mm

-

Wire band thickness:

-

0.35-0.70mm

-

Overall Dimension:

-

1170*1345*1700

-

Motor power:

-

5.5kw

-

Weight:

-

1800kg

Quick Details

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

SSS

-

Weight (KG):

-

1400

-

Marketing Type:

-

Hot Product 2021, Hot Product 2021

-

Nominal pressure:

-

250KN

-

Capacity:

-

12-18 boxes/min

-

Slide Strokes Per Minute:

-

100-140 times/min

-

Wire band width:

-

100-130mm

-

Wire band thickness:

-

0.35-0.70mm

-

Overall Dimension:

-

1170*1345*1700

-

Motor power:

-

5.5kw

-

Weight:

-

1800kg

Product Description

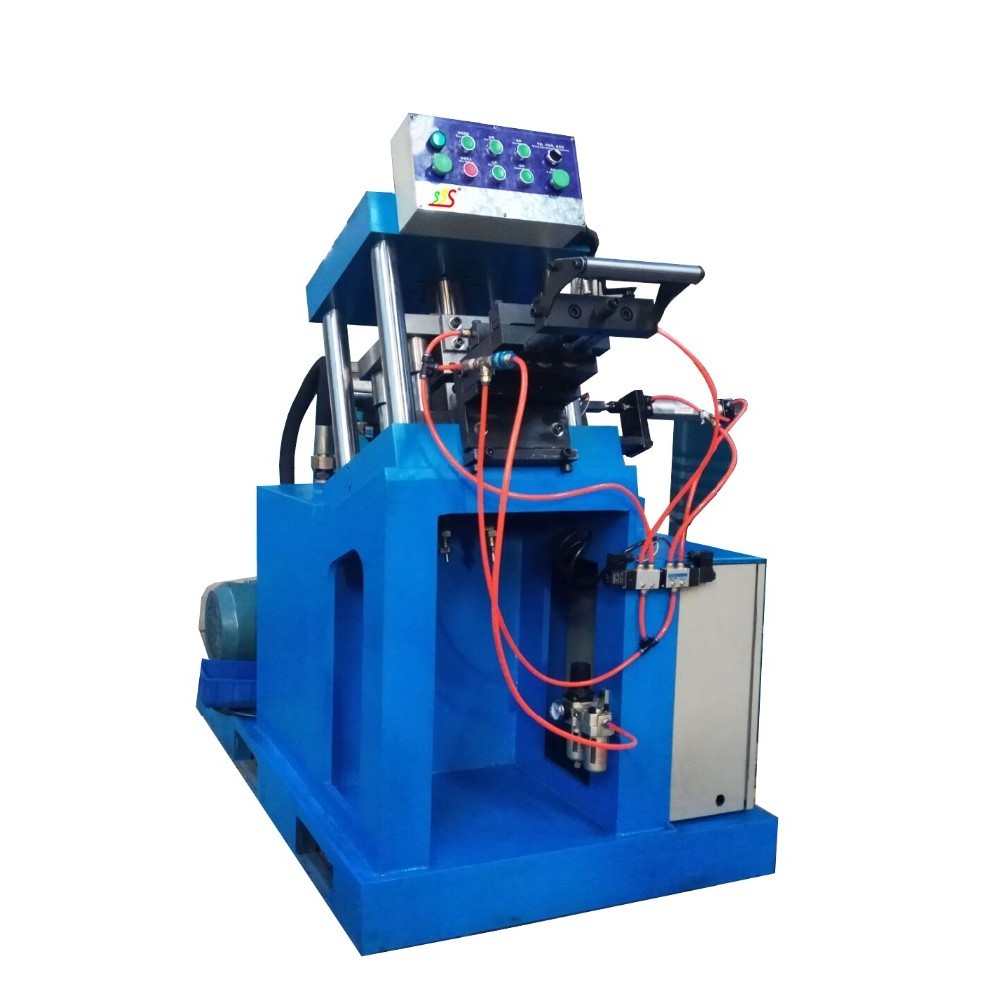

Hydraulic Pressure Automatic Staple Nail Making Machine for Office Use

This machine has abandoned the traditional heavy-duty punching machine, adopts the hydraulic system as the execution component, and uses the centralized control of the PLC microcomputer.

Features

A. Suitable for T, F, TN series staple pins

B. Hydraulic pressure system is adopted in this machine instead of traditional heavy punching type.

C. PLC microcomputer centralized control

D. Advantages: High speed Safety operation Stable performance Low noise

E. With 200-wire wire band, 2 strips can be produced every stroke.

Fully automatic brad strip staples making machine

Features

A. Suitable for T, F, TN series staple pins

B. Hydraulic pressure system is adopted in this machine instead of traditional heavy punching type.

C. PLC microcomputer centralized control

D. Advantages: High speed Safety operation Stable performance Low noise

E. With 200-wire wire band, 2 strips can be produced every stroke.

Fully automatic brad strip staples making machine

Technical Data

|

Specifications

|

Unit

|

SSS-TJB-WJ24

|

|

|

|

23 series

|

|

Nominal Pressure

|

KN

|

250

|

|

Number of strokes

|

Times/min

|

100-140

|

|

Wire band width

|

mm

|

100-130

|

|

Wire band thickness

|

mm

|

0.35-0.7

|

|

Capacity

|

Boxes/min

|

12-18

|

|

Dimensions(L*W*H)

|

mm

|

1345*1170*1700

|

|

Motor

|

Kw

|

5.5

|

|

Weight

|

Kg

|

1400

|

Related Machines

Water tank wire drawing and flattening integrated machine

High speed water tank wire drawing and flattening integrated machine adopts 17 molds and 4 groups of cone type pulley wheels, all wheels with tungsten carbide coating. The flattening machine adopts tungsten carbide wheel with high hardness and shining surface, which can ensure the exact flattening thickness. This group of machines can work together smoothly like one machine with one starting button.

|

Specifications

|

Unit

|

Model SSS-LB150

|

Model SSS-LB350

|

|

Speed

|

m/min

|

≤1000

|

≤1000

|

|

Inlet wire dia. range

|

mm

|

2.0-1.8

|

3.8-3.6

|

|

Outlet wire dia. Range

|

mm

|

0.55-0.43

|

1.5-1.15

|

|

Thickness tolerance

|

mm

|

±0.01

|

±0.01

|

|

Dimensions(L*W*H)

|

mm

|

6000*1500*1800

|

3000*1600*1800

|

|

Motor

|

Kw

|

22

|

40

|

|

Weight

|

Kg

|

3500

|

3800

|

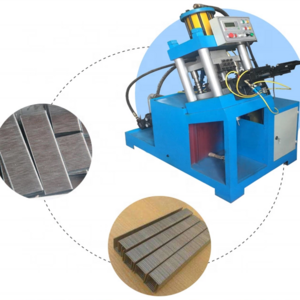

Wire flattening machine.

This single wire flattening machine adopts tungsten carbide alloy pressing roller, which has the advantages of high hardness and good brightness of the surface of the pressing wheel, and stepless speed change.

Water cooling in the pressing roller effectively extends the life of the alloy roller.

|

Specifications

|

Unit

|

Model SSS-YB150

|

Model SSS-YB200

|

Model SSS-YB300

|

|

Speed

|

m/min

|

0-350

|

0-350

|

0-350

|

|

Wire thickness

|

mm

|

0.3-1.0

|

0.5-1.5

|

1.0-2.2

|

|

Thickness tolerance

|

mm

|

±0.01

|

±0.01

|

±0.01

|

|

Dimensions(L*W*H)

|

mm

|

1800*760*1280

|

1800*760*1280

|

2000*800*1350

|

|

Motor

|

Kw

|

3

|

3

|

5.5

|

|

Weight

|

Kg

|

460

|

475

|

530

|

210-spool pay-off SSS-JX210

Straighten each wire through the wire take-up spool.

Each wire is equipped with a pulley cycloid device, and the pulley cycloid device sends the wire to the straightening wheel in the order of the wire. The bent wire will be automatically straightened by the straightening wheel to meet the qualified requirements.

Advantages:

Each wire gets the same pulling force

Even thickness

Smooth wire band

|

Specifications

|

Unit

|

SSS-TJB-JX210

|

|

Working speed

|

m/min

|

0-13

|

|

Wire band width

|

mm

|

50-120

|

|

Wire band thickness

|

mm

|

0.35-0.45

|

|

Dimensions (L*W*H)

|

mm

|

42000*1500*1700

|

|

Motor

|

Kw

|

7.5+4+9

|

|

Weight

|

Kg

|

3800

|

Wire band gluing machine

This group of machines including wire pay-off frame, with leveling and straightening equipment at front and rear part of the production line. The production line can glue the wires automatically and dry the wire band automatically.

|

Specifications

|

Unit

|

Model SSS-BXJ-JX150

|

|

Speed

|

m/min

|

0-13

|

|

Wire band width

|

mm

|

50-120

|

|

Wire band thickness

|

mm

|

0.35-1.85

|

|

Dimensions(L*W*H)

|

mm

|

2800*1500*1700

|

|

Motor

|

Kw

|

3+9

|

|

Weight

|

Kg

|

1100

|

Staple Forming Machine

To press and form the wire band to the final product staples/staple pins

This machine has abandoned the traditional heavy punch press, adopting the hydraulic system as the executive part, utilizing the PLC system, which has the characteristics of safe operation, stable performance, low noise and so on. Compared with the traditional punch machine, the speed is greatly increased.

This machine has abandoned the traditional heavy punch press, adopting the hydraulic system as the executive part, utilizing the PLC system, which has the characteristics of safe operation, stable performance, low noise and so on. Compared with the traditional punch machine, the speed is greatly increased.

|

Specifications

|

|

Unit

|

SSS-U25

|

SSS-U60

|

|

|

Nominal Pressure

|

|

KN

|

250

|

630

|

|

|

Slide Strokes Per Minute

|

|

times/min

|

90-170

|

80-100

|

|

|

Wire band width

|

|

mm

|

60-120

|

60-130

|

|

|

Wire band thickness

|

|

mm

|

0.4-0.7

|

1.0-1.35

|

|

|

Dimensions L*W*H

|

|

mm

|

1300*1200*1550

|

1300*1250*1650

|

|

|

Motor

|

|

Kw

|

4

|

5.5

|

|

|

Weight

|

|

Kg

|

1500

|

1700

|

|

Automatic staple packaging machine

Power of main motor: 80W

Max. Designed capacity: 40 boxes/min

Machine dimension: 1.2×1.1×1.5m(L×W×H)

Machine weight: about 150Kg

Size of carton: max. 125×45×30mm(L×W×H)

min. 120×20×15mm (L×W×H)

Noise:less than 85 db

Max. Designed capacity: 40 boxes/min

Machine dimension: 1.2×1.1×1.5m(L×W×H)

Machine weight: about 150Kg

Size of carton: max. 125×45×30mm(L×W×H)

min. 120×20×15mm (L×W×H)

Noise:less than 85 db

|

Technical parameters

|

Unit

|

SSS-BZJ-OS

|

|

Packing speed

|

boxes/min

|

1-18

|

|

Weight of a box

|

g

|

5-20

|

|

Dimension of box

|

mm

|

(100~120)x(30~65)x(20~40)

|

|

Weight of machine

|

kg

|

120

|

|

Dimension of machine

|

mm

|

1300x1100x1300

|

|

Air consumption:

|

L

|

3-10

|

|

Vacuum suction

|

Mpa

|

0.5-0.8

|

Customer visit

Favorable Comments

Packing & Delivery

1. Shipping port: Shanghai

2. Validity: within 30 days

3. Payment terms: 30% T/T down payment in advance and 70% before shipment

4. Warranty: 1 year from date of installation

5. Installation/Operation/Service/Maintenance Manual: Provided In English

6. In wooden pallet, In plastic film, the spare parts and cabinet packed by wooden box.

2. Validity: within 30 days

3. Payment terms: 30% T/T down payment in advance and 70% before shipment

4. Warranty: 1 year from date of installation

5. Installation/Operation/Service/Maintenance Manual: Provided In English

6. In wooden pallet, In plastic film, the spare parts and cabinet packed by wooden box.

Our Company

SSS HARDWARE INDUSTRY CO., LTD.

specializes in thread rolling machine, nail making machine, high speed nail making machine, wire collating machine, nail polishing machine, wire drawing machine, staple making machines and all kinds of nails . Our factory covers an area of 60,000 square meters and owns 300 sets of equipment. We are supported by seven branch work plants to ensure our good quality and prompt delivery. Quality is our priority and your satisfaction is what we are striving for.

Our products are very popular in UK , Italy, Germany, France, Poland, Slovenia, Bulgaria, Belarus, Serbia, Russia, Canada,

America, Mexico, Korea, Brazil, Argentina, Colombia, Guatemala, Venezuela, South Africa & New Zealand. You can totally rest assured of our guaranteed quality and our good after-sales service. Please feel free to contact us for more details including prices.

Our products are very popular in UK , Italy, Germany, France, Poland, Slovenia, Bulgaria, Belarus, Serbia, Russia, Canada,

America, Mexico, Korea, Brazil, Argentina, Colombia, Guatemala, Venezuela, South Africa & New Zealand. You can totally rest assured of our guaranteed quality and our good after-sales service. Please feel free to contact us for more details including prices.

Looking forward to cooperating with you soon based on our all-time guaranteed quality, our best price and service !

FAQ

Q: What is the warranty ?

A: One year warranty from the date when machine is received, any fault except for wrong operation during warranty period could be repaired freely. But the travel and hotel expenses should be paid by buyer.

Q: What is the after sale service?

A: We provide full manual book and 24 hours on-line trouble shooting service if any operation problem or break down.

Q: What about the shipping methods?

A: Sea freight, air freight, land freight and express. Delivery service to the port or to door is available.

Q: How long is your lead time?

A: Depend on the machine and order quantity. Usually within 35 ~ 50 days.

Q: What is your terms of payment ?

A: Payment<=5000USD, 100% in advance.

Payment>=5000USD, 30% T/T in advance, balance payment before shipment.

Q: What kind of payment ways can you accept?

A: T/T, L/C and so on.

A: One year warranty from the date when machine is received, any fault except for wrong operation during warranty period could be repaired freely. But the travel and hotel expenses should be paid by buyer.

Q: What is the after sale service?

A: We provide full manual book and 24 hours on-line trouble shooting service if any operation problem or break down.

Q: What about the shipping methods?

A: Sea freight, air freight, land freight and express. Delivery service to the port or to door is available.

Q: How long is your lead time?

A: Depend on the machine and order quantity. Usually within 35 ~ 50 days.

Q: What is your terms of payment ?

A: Payment<=5000USD, 100% in advance.

Payment>=5000USD, 30% T/T in advance, balance payment before shipment.

Q: What kind of payment ways can you accept?

A: T/T, L/C and so on.

Contact Us

Hot Searches