- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

620

-

Product name:

-

Steel Blade Bending Machine for sale

-

total power:

-

10kw

-

pressure:

-

0.6-0.8Mpa

-

Application:

-

Rotary die mould making

-

Rule height:

-

22-28mm

-

Processing tool material:

-

Straight knife bar and arc bar

-

Diameter:

-

220-800mm

-

More function:

-

Cutting Slotting Notching Lipping Perforation

-

Degree of automation:

-

fully automatic

-

Size:

-

1350*1400*1900mm/620kg

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZONGXIN

-

Year:

-

New

-

Weight (KG):

-

620

-

Product name:

-

Steel Blade Bending Machine for sale

-

total power:

-

10kw

-

pressure:

-

0.6-0.8Mpa

-

Application:

-

Rotary die mould making

-

Rule height:

-

22-28mm

-

Processing tool material:

-

Straight knife bar and arc bar

-

Diameter:

-

220-800mm

-

More function:

-

Cutting Slotting Notching Lipping Perforation

-

Degree of automation:

-

fully automatic

-

Size:

-

1350*1400*1900mm/620kg

CNC Automatic Steel Bar Bending Machine Steel Rule Metal Carbon Bender Steel Blade Bending Machine for sale

CNC Automatic Steel Bar Bending Machine Steel Rule Metal Carbon Bender Steel Blade Bending Machine for sale

Main parameters of CNC Automatic Steel Bar Bending Machine Steel Rule Metal Carbon Bender Steel Blade Bending Machine for sale:

| Processing material |

Straight knife/thread |

1.42 Circular/Rotary die cutter |

|

1.42 Straight compression line |

||

|

1.42 Straight large end line(2.84) |

||

|

Arc cutter/line |

R220-800 Circular arc cutter | |

| R220-800Arc pressing line | ||

| R220-800 Arc-shaped large end line(2.84) | ||

|

Basic function |

Bridging |

Motor driven automatic bridge crossing, bridge height automatically adjustable; canAutomatically adjust the bridge width according to the drawings; Can automatically process the head and tail bridge positions |

|

Punching |

It can automatically punch according to the drawing or at the designated position on the drawing | |

|

Lipping |

Motor driven automatic lipping, with adjustable lipping size |

|

|

Oblique/bevel |

Motor driven automatic oblique cutting, which can make the arc direction cutting more fitting |

|

|

Perforating |

Can automatically process perforating with a tooth width of 3mm or more, and the depth can be automatically adjusted |

|

| Total power | 10KW | |

| Pressure | 0.6-0.6MPA | |

| Machine size | 1350*1400*1900mm/620kg | |

Main features of CNC Automatic Steel Bar Bending Machine Steel Rule Metal Carbon Bender Steel Blade Bending Machine for sale:

1. The entire machine is powered by an electric motor and can automatically adapt to arc cutters and wire pressing with a diameter of 220-800. At the same time, the pressure of the cutting tool is automatically adjusted, without the need for manual operation throughout the entire process.

2. Independently developed a dedicated operating system for circular molds, which is compatible with scaled/non scaled drawings (effectively reducing the threshold for circular mold drawing), and can automatically repair arcs for scaled drawings without the need for secondary modifications, greatly improving work efficiency. The software is designed for lifelong free maintenance and upgrades for customers, and software functions can also be customized according to customer requirements.

3. Can automatically process a right angle chip remover, with a built-in eagle beak formed in one go for better chip removal effect

4. Equipped with oblique cutting function for cutting edge, no need to manually polish the cutting edge, resulting in better cutting effect, higher safety and efficiency

5. Straight knife processing can automatically open the back according to the drawing, and the loading effect is more in line with the drum

6. Lifetime free upgrade of system and control board

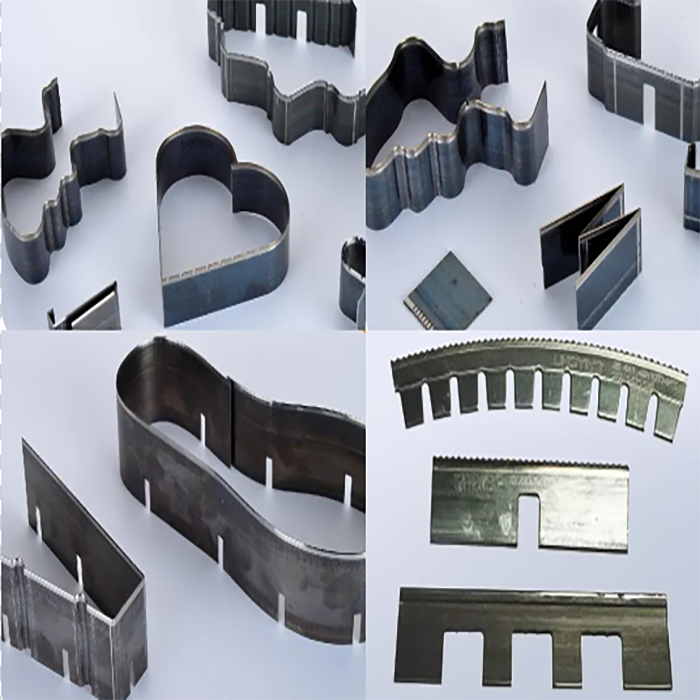

None joint knift/blade effect show:

1.Solve the problem of plat combine knift loose.

2.Solving the problem of the big quantity die cutting work, the rotary die knife may break off from the back section or bridge position.

3.Solve the problem of continuous die-cutting at the arc of the slotting cutter, as the bottom support surface of this non segmented cutter is large.

4.Solve the problem of cutting tool deviation at the arc of the slotting cutter.

Final products:

|

Packing:normal standard packing/as your requirement

|

||||

|

Shipping(normally arrive port time in work days)

|

||||

|

Destination

|

Express

Fedex/DHL/TNT |

By sea

|

By air

|

By EMS

|

|

North Ameria

|

3-10days

|

15-25days

|

5-7days

|

10-15days

|

|

South Ameria

|

3-10days

|

15-25days

|

5-7days

|

10-15days

|

|

European Countries

|

5-10days

|

15-30days

|

5-7days

|

10-15days

|

|

Asia Countries

|

3-10days

|

20-30days

|

5-7days

|

10-15days

|

|

Africa Countries

|

5-10days

|

35-45days

|

5-7days

|

10-15days

|

|

The Middle East

|

5-10days

|

35-40days

|

5-7days

|

10-15days

|

|

Australia

|

3-7days

|

25-35days

|

5-7days

|

10-15days

|

1. 24 hours online service.

2. On time delivery.

3. Good after-sales service.