- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Aoqiang

-

Model Number:

-

PB500/600/800

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

3000x1200x1700mm

-

Weight:

-

900 KG

-

Name:

-

Garbage bag making machine

-

Model:

-

PB600

-

Max. Bag-making Width:

-

550mm

-

Bag-making Length:

-

20-1800mm

-

Bag-making Thickness:

-

0.008-0.15mm

-

Bag-making Speed:

-

30-150pcs/min

-

Main Motor Power:

-

1.5kw

-

Machine Weight:

-

900kg

-

Machine Dimension:

-

3000x1200x1700mm

-

Bag-making Type:

-

Vest bags in roll; Plain mouth bags in roll

Quick Details

-

Machine Type:

-

Cutting Machine

-

Bag Type:

-

GARBAGE BAG

-

Material:

-

Plastic

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Aoqiang

-

Model Number:

-

PB500/600/800

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

3000x1200x1700mm

-

Weight:

-

900 KG

-

Name:

-

Garbage bag making machine

-

Model:

-

PB600

-

Max. Bag-making Width:

-

550mm

-

Bag-making Length:

-

20-1800mm

-

Bag-making Thickness:

-

0.008-0.15mm

-

Bag-making Speed:

-

30-150pcs/min

-

Main Motor Power:

-

1.5kw

-

Machine Weight:

-

900kg

-

Machine Dimension:

-

3000x1200x1700mm

-

Bag-making Type:

-

Vest bags in roll; Plain mouth bags in roll

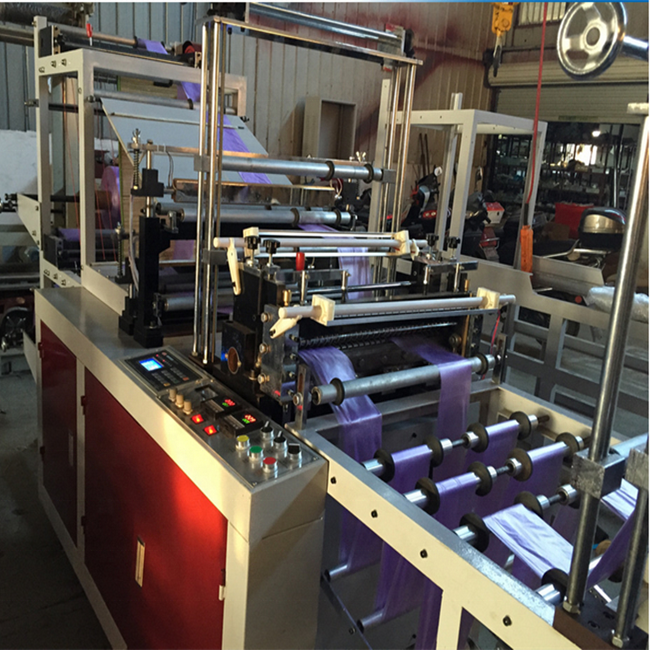

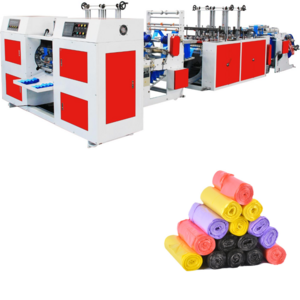

Poly roll garbage bag making machine

1. Feature:

This double-layer high-speed continuous rolled t-shirt bag making machine is used to make rolling t-shirt bag(vest bag) and rolling flat bag(plain mouth bag) with double layer.

It is a coumputer-controlled full automatic bag making machine which combines optic, electric, gas and instrument control. It is suitable for making bags of many kinds of heat melting film such as PE, PP and PVC etc.

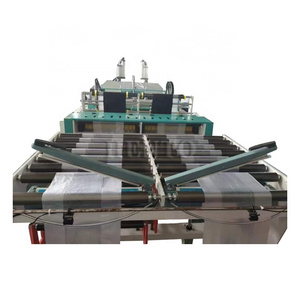

There are such features as photoelectric control automatic material feeding, photoelectric tracing color code in color printing, double working-position feeding and double working position sealing, step or servo motor which controls speed and length of bag, computer counting and cutting.

2. Main Technical Specification

3. Profile Display

4.Characteristics:

This machine, especially-designed point-cut rolling dually purpose one for vest & flat bags, is controlled by a computer, The step(servo)setting length system reduces the sealing-cutting dimensions errors, and the installation of photoelectric eyes track help make the position of figure of printing bag accurate. The computer numerical control can be selected to adjust the length of bag. The machine will automatically stop and sound a warning if there is something wrong with the printing bags.Packaging & Shipping

Our engineer can be available to service machinery overseas.

1) Machines with good quality in one year, life-long maintenance

2) We have many machines can be monitored via the Internet, solve customer requirements in a timely manner.

3) We have several senior,continuous innovation and reform, in order to ensure the quality of mechanical stability.

4) Undertake various non-standard machinery, solve the customers' requirements.