- Product Details

- {{item.text}}

Quick Details

-

Bending Precision (Deg):

-

0.01

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

lyz

-

Power (kW):

-

6

-

Weight (KG):

-

3000

Quick Details

-

Machine Type:

-

bending machine

-

Bending Radius (mm):

-

9 - 30

-

Max. Bending Angle (Deg):

-

180

-

Bending Precision (Deg):

-

0.01

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

lyz

-

Power (kW):

-

6

-

Weight (KG):

-

3000

Product Description

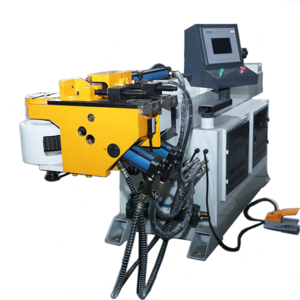

The copper aluminum pipe tube coil straightening cutting and bending machine is used to process single aluminum/ copper / Bundy tube with de-coiling, straightening and cutting machine and bending function in one line automatically. Compare to traditional manual process, the full-automatic machine improve the work efficient and save labor cost greatly.

Main Features

1.Three-part clamping die to minimize tube distortion, get smooth cutting end surface.

2.High accuracy concentricity ensures to get good welding quality in following process.

3.Chipless cutting with 360°rotary cutting and stretching with two points clamping.

4.Servo drive system, PLC control system, and touch screen control to get high accuracy product size with easy operation and maintenance.

Technical Parameter

| 1 | Tube Material |

Copper tube / Aluminum tube /Bundy tube |

| 2 | Tube Diameter | Φ3-Φ20 |

|

3

|

Tube Wall Thickness | 0.3-1.0mm |

| 4 | Bending Capacity | Single tube |

| 5 | Bending Angle | 1~180 degree |

| 6 | Bending Radius | R9-R30 |

| 7 | Bending Times | Up to 110 times/cycle |

| 8 | Feeding length | 0-600mm/time, max. 3 times |

| 9 | Rotary Table Size | Φ2000mm |

| 10 | Control System | PLC control / Touch Screen |

| 11 | Air Pressure | 0.5-0.6MPa |

| 12 |

Motor Power |

13KW |

| 13 | Electric System | 380V, 50Hz, 3Phae (Customized) |

| 14 | Dimension | 4800 x 1300 x 1680 mm (Excluded Table) |

| 15 | Weight | About 3000 KG |