- Product Details

- {{item.text}}

Quick Details

-

Max Speed:

-

600-2000BPH

-

Voltage:

-

110v/220v

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HNOC

-

Dimension(L*W*H):

-

1180*1020*1620mm

-

Weight:

-

400 KG

-

Name:

-

fill seal machine tube fill seal machine

-

Tube material:

-

Plastic Tube/Composite Tube

-

Motor Power:

-

0.75KW

-

Required Air Compressor:

-

0.55-0.65MPA / ≥3kw 100L

-

Filling Accuracy:

-

≤±1%

-

Filling range:

-

5-50ml/50-250ml

-

Bottle Diameter:

-

15-50mm

-

Bottle Height:

-

60-220mm

-

Power Supply:

-

Electric

-

Material:

-

304 Stainless Steel

Quick Details

-

Packaging Type:

-

Tube

-

Packaging Material:

-

Plastic, Metal

-

Driven Type:

-

Electric

-

Max Speed:

-

600-2000BPH

-

Voltage:

-

110v/220v

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HNOC

-

Dimension(L*W*H):

-

1180*1020*1620mm

-

Weight:

-

400 KG

-

Name:

-

fill seal machine tube fill seal machine

-

Tube material:

-

Plastic Tube/Composite Tube

-

Motor Power:

-

0.75KW

-

Required Air Compressor:

-

0.55-0.65MPA / ≥3kw 100L

-

Filling Accuracy:

-

≤±1%

-

Filling range:

-

5-50ml/50-250ml

-

Bottle Diameter:

-

15-50mm

-

Bottle Height:

-

60-220mm

-

Power Supply:

-

Electric

-

Material:

-

304 Stainless Steel

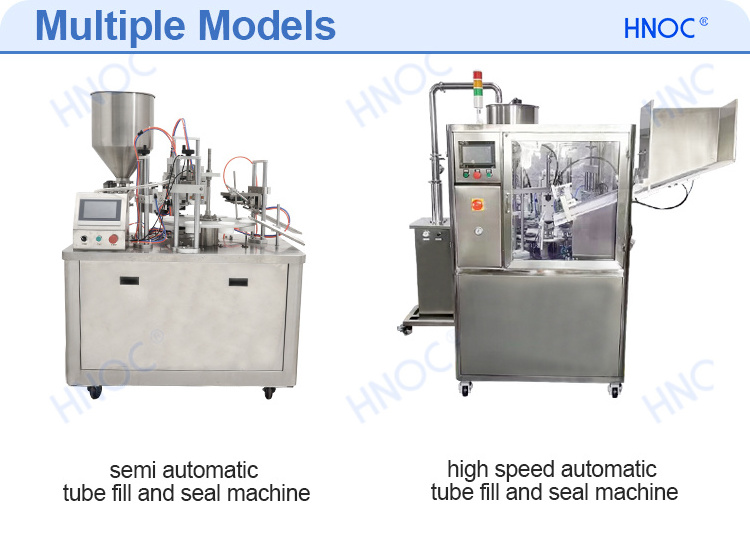

Product Description

Introduction

The tube fill seal machine is made of 304 stainless steel, fully automatic mechanical control, manual or automatic feeding tube, cursor induction, automatic benchmarking, quantitative filling, high measurement accuracy, complete and beautiful sealing, strong seal, good stability. This machine can be equipped with different specifications of irrigation heads to meet the installation requirements of different viscosity.

Application

Suitable for daily chemical, food, cosmetics, chemical industry and other industries.

Feature

1.

PLC control, intuitive and easy to operate, precisely filling and sealing.

2.

Frequency control, the production speed arbitrary regulation, automatic counting.

3.

Automatic stop function, no bottle will not filling and not torinese.

4.

Disc positioning filling, stable and reliable.

5.

High precision cam indexing control, positioning precision.

6.

There are two types of tail end shear designs: flat shear and curved shear, which can be configured according to factors such as tail shape or material.

7.

The cutting area should be free of burrs and flat, meeting the aesthetic requirements of the packaging.

Product Details

Wide Application

Product Parameters

|

Tube Material

|

Plastic Tube/Composite Tube

|

|

Voltage

|

110V/220V,50/60hz

|

|

Motor Power

|

0.75KW

|

|

Power

|

1500W

|

|

Required Air Compressor

|

0.55-0.65MPA / ≥3kw 100L

|

|

Filling Accuracy

|

≤±1%

|

|

Filling Speed

|

600-2000BPH

|

|

Filling range

|

5-50ml/50-250ml

|

|

Bottle Diameter

|

φ15-φ50mm

|

|

Bottle Height

|

60-220mm

|

|

Printing size

|

2*3mm

|

|

Machine Weight

|

390KG

|

|

Machine Dimensions

|

1180*1020*1620mm

|

Product Photograph

Recommend Product

Hot Searches