- Product Details

- {{item.text}}

Quick Details

-

Tolerance:

-

±1%

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

dingnuo

-

Model Number:

-

A36 A53

-

Application:

-

Engineering Structure

-

Product name:

-

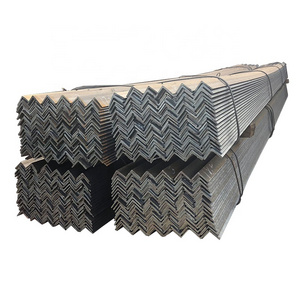

Steel Angle Bar

-

Keywords:

-

Angel Steel Bar

-

MOQ:

-

1 Ton

-

Length:

-

6m-12m

-

Thickness:

-

3-24mm

-

Surface treatment:

-

Non/Galvanized/As customized

-

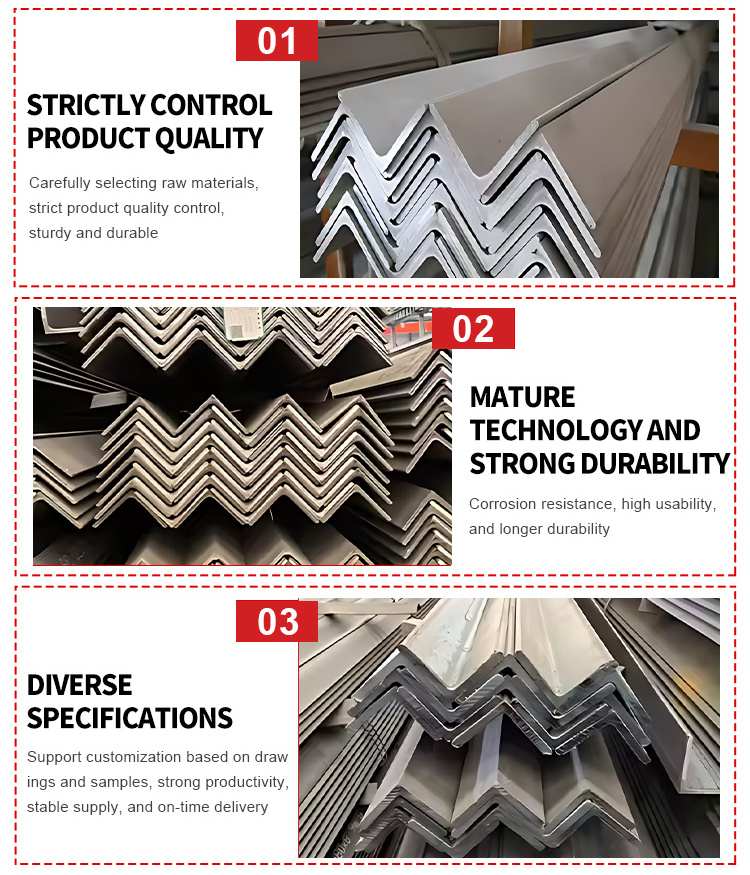

Quality:

-

High Quality. Inspection

-

Port:

-

Qingdao Tianjin

-

Surface:

-

Customer Request

Quick Details

-

Standard:

-

ASTM

-

Grade:

-

Q195-Q420 Series

-

Type:

-

Equal

-

Tolerance:

-

±1%

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

dingnuo

-

Model Number:

-

A36 A53

-

Application:

-

Engineering Structure

-

Product name:

-

Steel Angle Bar

-

Keywords:

-

Angel Steel Bar

-

MOQ:

-

1 Ton

-

Length:

-

6m-12m

-

Thickness:

-

3-24mm

-

Surface treatment:

-

Non/Galvanized/As customized

-

Quality:

-

High Quality. Inspection

-

Port:

-

Qingdao Tianjin

-

Surface:

-

Customer Request

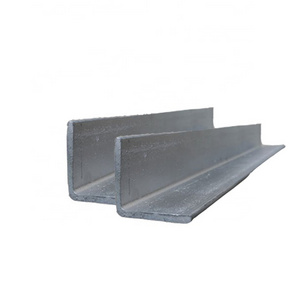

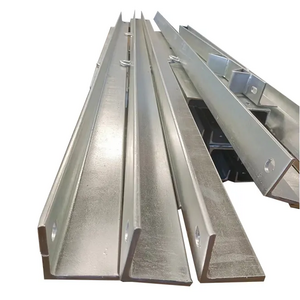

Steel Frames 75x75 Angle 50x50x5 mm Galvanized Punched Steel Slotted Cold Drawn Angle Equal ASTM Cutting Welding Included

Products Description

|

Product Name

|

Angle Steel

|

|

Technique

|

Hot Rolled/Cold Rolled

|

|

Grade

|

S235JR-S335JR Series,St-37/52,Q195-Q420,etc.Q235/Q345/SS400/ST37-2/ST52/Q420/Q460/S235JR

|

|

Size

|

20*20mm*3mm-200*200mm*20mm

|

|

Thickness

|

2-20mm

|

|

Length

|

5.8m,6m.9m,12m ,as customer's required

|

|

Processing Service

|

Bending, Welding, Decoiling, Punching, Cutting

|

|

Standard

|

AISI,ASTM,DIN,JIS,BS,GB/T

|

|

Tolerance

|

±1%

|

|

MOQ

|

1Ton

|

|

Application

|

It is widely used in various building structures and engineering structures, such as roof beams, bridges, transmission towers,lifting and transportation machinery, ships, industrial furnaces, reaction towers, container racks and warehouse shelves, etc.

|

|

Delivery Term

|

EXW FOB CIF CFR

|

|

Payment Term

|

30% TT 70% final payment

|

|

Hot Selling Countries

|

We are one of the largest domestic exporters and sell to various foreign markets

|

|

Company advantage

|

1.Complete specifications, support customization

2.Strict selection of materials, precise cutting 3.We support factory inspection and welcome partners from all walks of life to visit and achieve win-win cooperation |

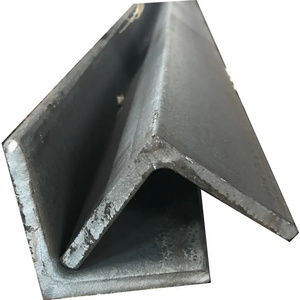

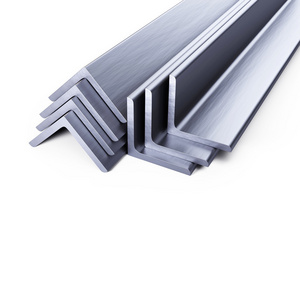

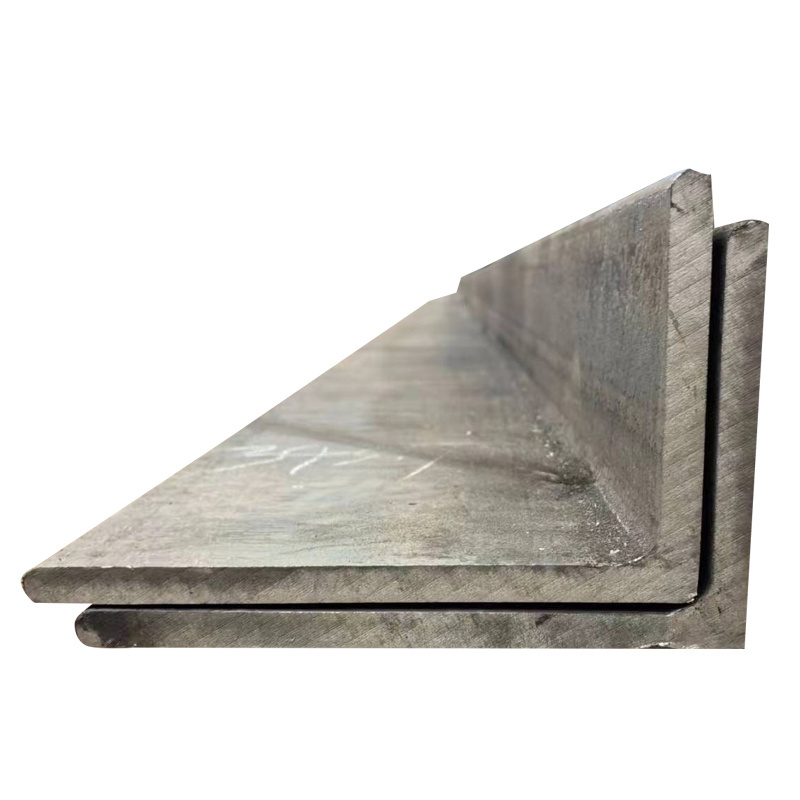

Angle steel is a long strip of steel with two sides perpendicular to each other. There are equilateral angle steel and unequal angle steel. The width of both sides of the equilateral angle steel is equal. Its specifications are expressed in millimeters of side width × side width × side thickness. Angle steel can be composed of various stress-bearing components according to different needs of the structure, and can also be used as a connector between components. It is widely used in various building structures and engineering structures. Among them, unequal angle steel can be divided into two types: unequal sides and equal thickness and unequal sides and unequal thickness. The cross-sectional height of the unequal angle steel is calculated according to the long side width of the unequal angle steel. Refers to steel with an angular cross-section and unequal lengths on both sides. Unequal angle steel is widely used in various metal structures, bridges, machinery manufacturing and shipbuilding industries, various building structures and engineering structures.

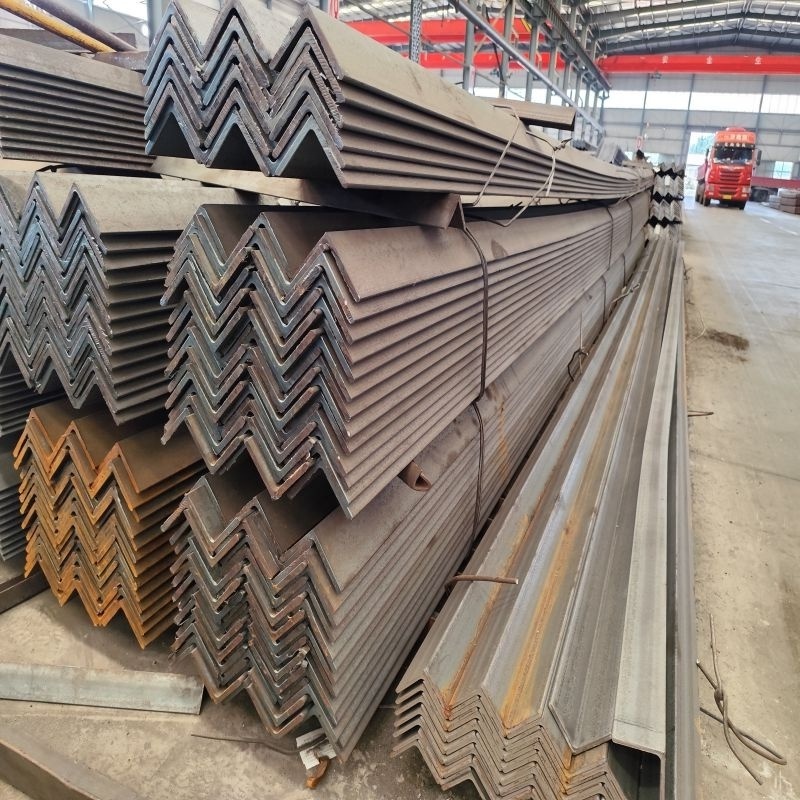

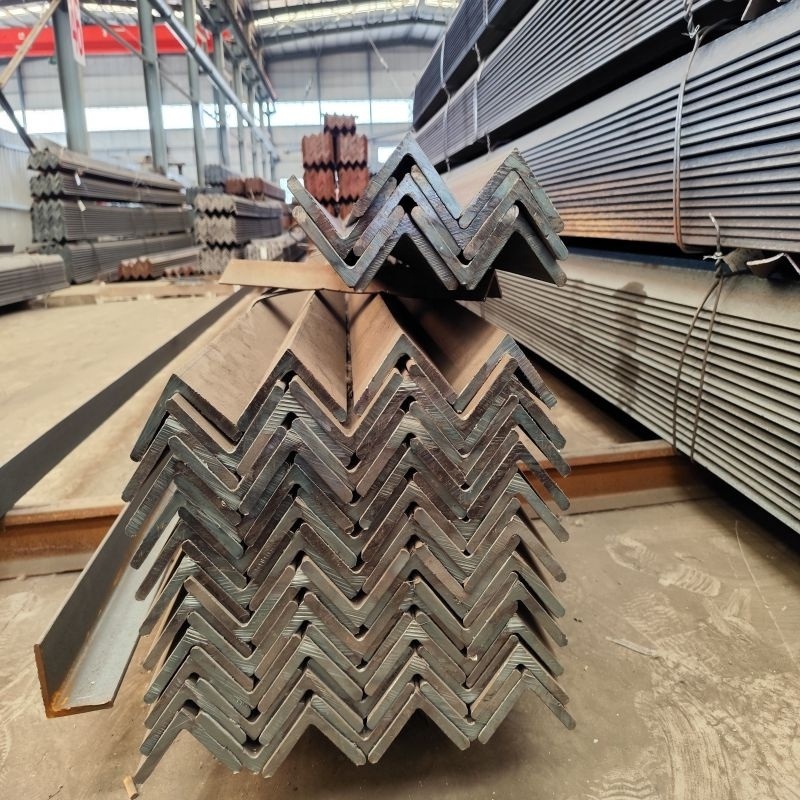

Factory display

First of all, the production of angle steel starts with the preparation of steel billets. Steel billets are produced by steel mills in furnaces Melted and cast. Generally speaking, the materials of angle steel include carbon steel, alloy steel and stainless steel. The quality of the steel billet has an important impact on the quality of the final product. Therefore, it is necessary to ensure that the steel billet meets relevant standards.

The second step is the heating of the billet. The steel billet is heated to a certain temperature in a heat treatment furnace so that it can be formed into the desired angle and shape during subsequent processing. The heating temperature depends on the material and size of the steel billet. After heating, the steel billet is fed into the rolling mill for rolling. Angle steel rolling mill is a piece of equipment specially used for angle steel production. It presses steel billet into the required shape and size. During the rolling process, the steel billet is pressed multiple times through different rolls to gradually form the desired angle and shape. The rolling mill needs to be adjusted according to the requirements of the specific product to ensure the quality and dimensional accuracy of the angle steel. After rolling is completed, the angle steel is cooled through a cooling system. The purpose of cooling is to lower the temperature of the steel and increase its hardness and strength. The cooling method can be natural cooling or water cooling, depending on the requirements of the steel material.

The final step is to trim and cut the angle steel. Trimming is mainly to remove burrs and uneven parts produced during the rolling process to improve the surface quality and appearance of the angle steel. Cutting is to cut the angle steel into the required size according to the length requirements specified by the user.

Product application

Angle steel can be used to form various stress-bearing components according to the different needs of the structure, and can also be used as connectors between components. It is widely used in various building structures and engineering structures, such as beams, bridges, transmission towers, lifting and transportation machinery, ships, industrial furnaces, reaction towers,container racks, and warehouse shelves. It is also commonly used to protect columns, retaining walls, and other vulnerable parts.

Angle steel belongs to carbon structural steel for construction. It is a simple section steel, mainly used for metal components and plant frames. It has good weldability, plastic deformation ability and certain mechanical strength in use. The raw material billet for the production of angle steel is a low-carbon square billet, and the finished angle steel is delivered in hot-rolled forming, normalized or hot-rolled state..

Marketing Campaign

Hot Searches