It is designed to automate the process of forming Ag and PBR roof panels, which are commonly used in the construction of metal roofs for various buildings, including warehouses, industrial facilities, agricultural structures, and more.

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

YUFA

-

Voltage:

-

208V or 220V or 240V or 380V or 440V

-

Dimension(L*W*H):

-

8000*1500*1800mm

-

Weight:

-

8500 kg

-

Feeding width:

-

914mm,1000mm,1200mm,or as your drawing design

-

Marketing Type:

-

Popular sell double layer machine

-

After-sales Service Provided:

-

Online Support Video Technical Support

-

Cutting blade material:

-

GCr12MoV Frequency Quenching

-

Raw material:

-

PPGI PPGL GI GL

-

Roller material:

-

45#steel Chrome Plated

-

Control system:

-

PLC(detla) System

-

Cutting type:

-

Automatic Hydraulic Cutting

-

Material thickness:

-

0.3-0.8mm Galvanized Steel

-

Frame material:

-

400 H-high Grade Steel

-

Main Motor Power:

-

5.5kw

-

Machine Color:

-

Client's Requriment

Quick Details

-

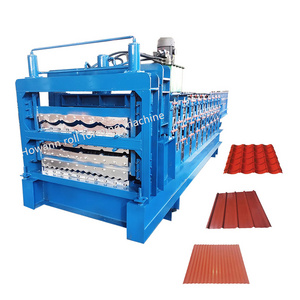

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

15 m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

YUFA

-

Voltage:

-

208V or 220V or 240V or 380V or 440V

-

Dimension(L*W*H):

-

8000*1500*1800mm

-

Weight:

-

8500 kg

-

Feeding width:

-

914mm,1000mm,1200mm,or as your drawing design

-

Marketing Type:

-

Popular sell double layer machine

-

After-sales Service Provided:

-

Online Support Video Technical Support

-

Cutting blade material:

-

GCr12MoV Frequency Quenching

-

Raw material:

-

PPGI PPGL GI GL

-

Roller material:

-

45#steel Chrome Plated

-

Control system:

-

PLC(detla) System

-

Cutting type:

-

Automatic Hydraulic Cutting

-

Material thickness:

-

0.3-0.8mm Galvanized Steel

-

Frame material:

-

400 H-high Grade Steel

-

Main Motor Power:

-

5.5kw

-

Machine Color:

-

Client's Requriment

Product Overview

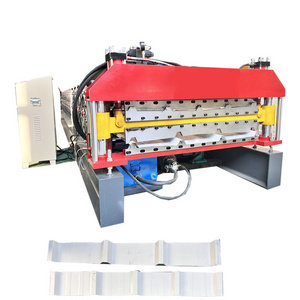

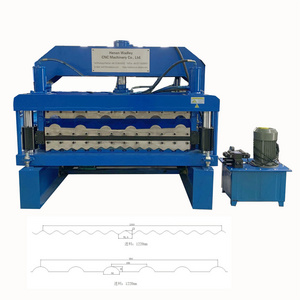

PBR&AG panel double layer roll forming machine/ 2in 1 roll forming machine

This one machine can produce two profiles products.A PBR (Purlin Bearing Rib) and AG roof panel double layer roll forming machine is a piece of industrial equipment used in the construction and manufacturing industry.

FEATURES AT A GLANCE

Up layer AG profile panel

Down layer PBR Profile panel

Double layer roll forming machine

PRODUCT SPECIFICATIONS

|

No

|

Item

|

Data

|

|

|

|

1

|

Shaft Diameter

|

75mm

|

|

|

|

2

|

Roller station

|

11&15 row stations

|

or customized

|

as your request

|

|

3

|

Thickness material

|

0.3-0.8mm

|

24ga to 29ga

|

|

|

4

|

Machine weight

|

18500lb

|

equal 8.5tons

|

|

|

5

|

Machine Size

|

27 feet long 5 feet wide

|

8*1.5*1.8m

|

|

|

6

|

Cutting

|

Automatic cutting as your set

|

|

|

|

7

|

Voltage

|

220V 3phase or single phase

|

208V 3phase

|

380V 3phase

|

|

8

|

Read out in inches

|

Read out in mm

|

English screen

|

Spanish screen

|

PRODUCT CONFIGURATION

All roll forming machinery is fully assembled at our factory in Hebei. Our Roll Forming Machines come with a 1 year

warranty for parts and labor. All machines will be made to customer personal requirements and profile.

warranty for parts and labor. All machines will be made to customer personal requirements and profile.

Details Images

Machine working flow

Double layer roll forming machine working flow

If you wanna see the double layer roll forming machine working video and flow, please contact Damon

More products for your choose

Drip Edge Roll Forming Machines

Drip Edge Roll Forming Machines

are versatile and can be customized to produce various drip edge profiles to meet different roofing requirements.

They are known for their efficiency, precision, and the ability to produce high-quality drip edges in large quantities, making them essential equipment for roofing and construction companies.

Simple ridge cap roll forming machine/CURVE MACHINE /RIDGE CAP BENDER

A Ridge Cap Roll Forming Machine

is a specialized piece of equipment used in the construction industry to manufacture ridge cap or ridge capping materials for roofing applications.

Ridge caps are the protective covers placed along the peak of a roof where two sloping roof sections meet.

They are essential for preventing water infiltration, protecting against weather elements, and giving the roof a finished

appearance.

Ridge caps are the protective covers placed along the peak of a roof where two sloping roof sections meet.

They are essential for preventing water infiltration, protecting against weather elements, and giving the roof a finished

appearance.

You can even make a house out of curving machine.

As long as you can think of it, I can help you do it, please contact me.

Top Hat Omega Profile Roll Forming Machine

A Hat Channel Roll Forming Machine

is a piece of industrial equipment used in the manufacturing of hat channels, which are commonly used in construction and other industries. Hat channels are typically shaped like the letter "U" or a hat, hence the name, and they are used as structural support or framing components in various applications, including in walls, ceilings, and roofs.

5tons hydraulic decoiler with car /manual decoiler/electric decoiler / 15,000LB UNCOILER WITH HYDRAULIC CAR

A Automatic decoiler with a hydraulic car

is a robust and versatile machine used in metal processing and manufacturing operations where large coils of material need to be unwound and fed into other machines. The hydraulic system provides the necessary power and control to handle heavy loads and ensure precise operation.

SALES AND SERVICE NETWORK

FAQ

1. Q: How to visit our company:

A: Fly to Beijing Airport: By fast train From Beijing South station to Cangzhou west station (1hour), then we can pick up you to factory(40min). Fly to Shanghai Airport: By fast train From Shanghai Hongqiao station to Cangzhou west station(4.5 hours), then we can pick up you to factory(40min).

2. Q: What should I provide if I want to customized machine?

A: U need provide profile drawing, material, thickness, voltage and your special requirements.

3. Q: What is the Warranty?

A: Within 12 mounts, all technical are ready to serve you at any time.

4. Q: What can you do if the machine broken?

A: Our machine's warranty period is 12 months, if the broken parts can't repair, we will send

new parts replace the broken parts free, but you need pay the express cost if after warranty period. we can negotiate to solve the problem, and we supply the technical support for whole life of equipment.

5. Q: If need technician to workshop to debug and teach, how to do?

A: We sent technician to your country to fix the machine. Buyer should bear cost including: visa, round trip ticket and suitable accommodation, also buyer should pay the salary 100 USD/day.

A: Fly to Beijing Airport: By fast train From Beijing South station to Cangzhou west station (1hour), then we can pick up you to factory(40min). Fly to Shanghai Airport: By fast train From Shanghai Hongqiao station to Cangzhou west station(4.5 hours), then we can pick up you to factory(40min).

2. Q: What should I provide if I want to customized machine?

A: U need provide profile drawing, material, thickness, voltage and your special requirements.

3. Q: What is the Warranty?

A: Within 12 mounts, all technical are ready to serve you at any time.

4. Q: What can you do if the machine broken?

A: Our machine's warranty period is 12 months, if the broken parts can't repair, we will send

new parts replace the broken parts free, but you need pay the express cost if after warranty period. we can negotiate to solve the problem, and we supply the technical support for whole life of equipment.

5. Q: If need technician to workshop to debug and teach, how to do?

A: We sent technician to your country to fix the machine. Buyer should bear cost including: visa, round trip ticket and suitable accommodation, also buyer should pay the salary 100 USD/day.

Hot Searches