- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v 50hz 3phrase

-

Power:

-

4.5kw

-

Dimension(L*W*H):

-

1553*771*1693mm

-

Weight:

-

150 KG

-

Machinery Function:

-

Cream Beater Chiffon Cake Batter Aeration Machine

-

Output product name:

-

cream whipping

-

Name:

-

Sponge cake batter Aeration Sour Cream Whipping Ma

-

Suitable cream:

-

Whipped Cream

-

Function:

-

Continuous Mixer Cotton Candy Aerator

-

Keyword:

-

high speed cake cream whipping machine

-

Type:

-

Fully Automatic

-

Advantage:

-

Easy Operation High Efficiency

-

Product name:

-

Continuous Cake Aerating Mixer Machine

-

Application:

-

Cake Bakery Machine

-

Material:

-

304 Stainless Steel

-

Suitable for:

-

light cream cake batter

Quick Details

-

Marketing Type:

-

Newest Machine

-

Brand Name:

-

hanbeter

-

Place of Origin:

-

China

-

Voltage:

-

380v 50hz 3phrase

-

Power:

-

4.5kw

-

Dimension(L*W*H):

-

1553*771*1693mm

-

Weight:

-

150 KG

-

Machinery Function:

-

Cream Beater Chiffon Cake Batter Aeration Machine

-

Output product name:

-

cream whipping

-

Name:

-

Sponge cake batter Aeration Sour Cream Whipping Ma

-

Suitable cream:

-

Whipped Cream

-

Function:

-

Continuous Mixer Cotton Candy Aerator

-

Keyword:

-

high speed cake cream whipping machine

-

Type:

-

Fully Automatic

-

Advantage:

-

Easy Operation High Efficiency

-

Product name:

-

Continuous Cake Aerating Mixer Machine

-

Application:

-

Cake Bakery Machine

-

Material:

-

304 Stainless Steel

-

Suitable for:

-

light cream cake batter

Product Effects

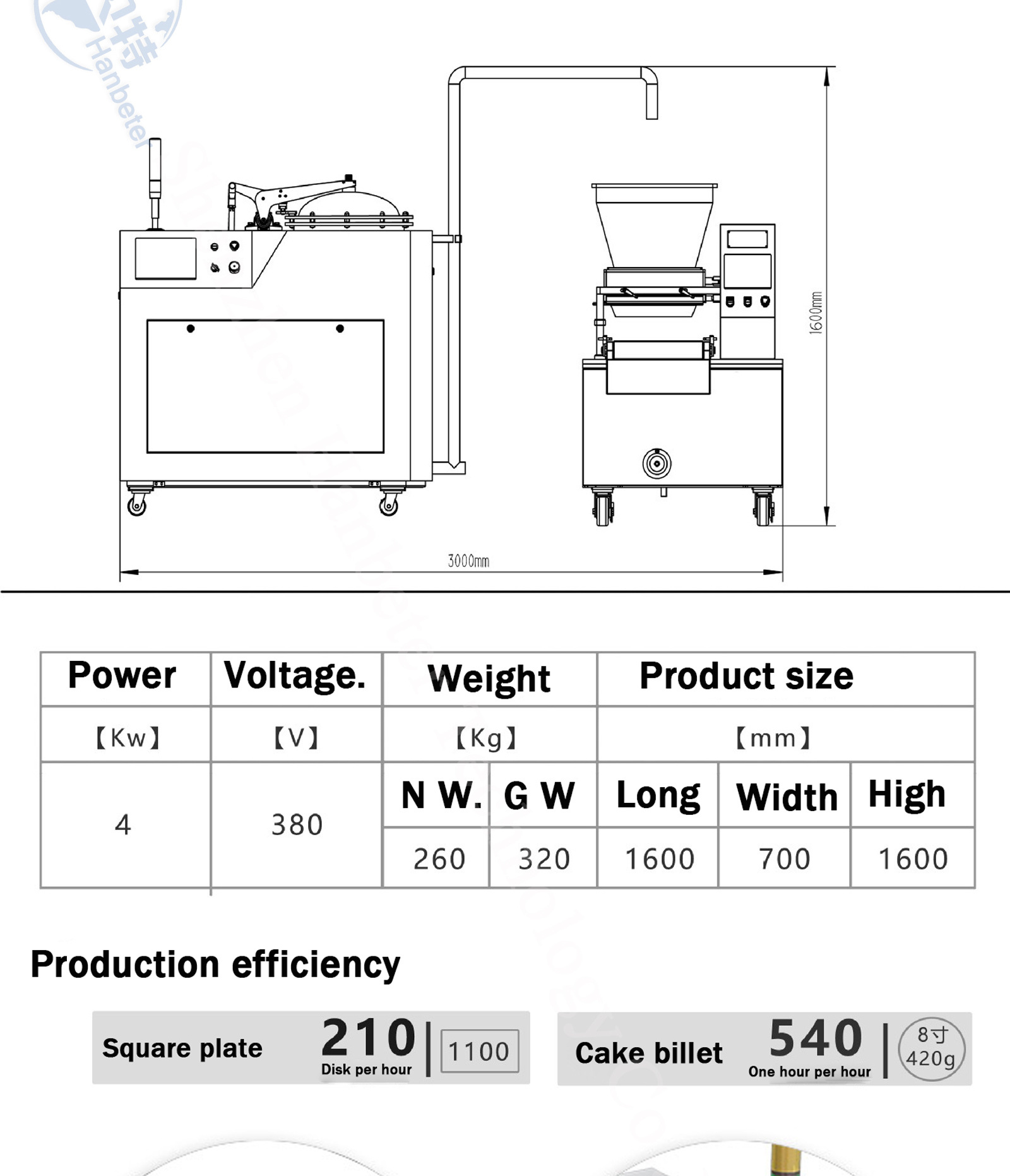

| Product Features | |

| Application fields | Snack food factory, Bakery |

| Dimension(L*W*H) | 1553*771*1693mm |

| Output product name | cream whipping |

| Warranty of core components | 1 Year |

| Name | Sponge cake batter Aeration Sour Cream Whipping Machine |

| Suitable cream | Whipped Cream |

| Function | Continuous Mixer Cotton Candy Aerator |

| Key Selling Points | Famous brand PLC |

| Voltage | 380v 50hz 3phrase |

| Machinery Test Report | Provided |

| Condition | New |

| Place of Origin | China |

| Warranty | 1 Year |

| Keyword | Chiffon Cake Machine Cream Whipping Machine |

| Showroom Location | None |

| Material | 304 Stainless Steel |

| Raw material | Flour, Egg |

| Weight | 320 KG |

| Suitable for | light cream cake batter |

| Brand Name | hanbeter |

| Video outgoing-inspection | Provided |

| Type | Fully Automatic |

| Applicable Industries | Hotels, Manufacturing Plant, Food & Beverage Factory, Food Shop, Food & Beverage Shops |

| Marketing Type | Newest Machine |

| Core Components | PLC, Bearing, Motor |

| Advantage | Easy Operation High Efficiency |

| Product name | Chiffon Cake Machine |

| Application | Cake Bakery Machine |

| Power | 4.5kw |

Cotton Candy Cake Batter Aeration Sour Cream Whipping Machine Automatic Marshmallow Aerating Machine

Introduction of Aerating Continuous Mixer Cotton Candy Aerator:

The Aerating Continuous Mixer Cotton Candy Aerator is with advanced technology, from mixing and cooling to high-speed whipping. The entire system consists of a batter system, a storage system, a whipping system, a conveying system, a cooling system and a control system. With such a continuous batter whipping system , which enables the cake ingredients to be mixed and beaten in a short time, and the beaten cake ingredients are automatically transported to the cake forming machine through the automatic feeding pump, ensuring that the product has the same batter ratio from the beginning to the end.

Application:

This Aerating Continuous Mixer Cotton Candy Aerator is suitable for a series of products such as Dorayaki, egg yolk pie, Moba cake, meat floss cake, Swiss roll, gold medal cake, sponge cake etc. It is the only choice for many large-scale enterprises.

working process for Aerating Continuous Mixer Cotton Candy Aerator:

Step 1: Turn on the display, start, automatically open the lid, add materials, time setting, inflate and material, and automatically discharge materials are all automated systems, no other operations are required.

Step 2: The storage barrel should be kept between 7°C and 15°C to prevent the weather from affecting the cake batter structure (the selection is determined based on the manufacturer's workshop environment), and then the material in the storage barrel is pumped to the The inflatable sending machine head is used for complete sending. This can adjust the proportion of inflating and sending according to customer needs! In the middle, it can save personnel to carry and release materials, and the ingredients can be continuously sent.

Hot Searches