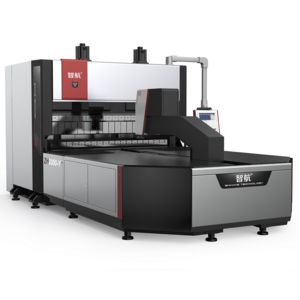

- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

400 mm

-

Width of Working Table (mm):

-

2500 mm

-

Dimension:

-

4500*2800*2800mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ZHENGHENG

-

Year:

-

new

-

Weight (KG):

-

14000

-

Motor Power (kw):

-

30 kw

-

Marketing Type:

-

New Product 2024

-

Warranty of core components:

-

2 years

-

Maximum diagonal length of sheet:

-

2400mm

-

Max folding:

-

2000mm

-

Max folding height:

-

165mm

-

Max Stainless steel thickness:

-

1.2mm

-

Max Al Alloy thickness:

-

3mm

-

Max Mild steel thickness:

-

2mm

-

Min.sheet thickness:

-

0.5mm

-

Servo axis:

-

13

Quick Details

-

Machine Type:

-

electro-hydraulic servo

-

Length of Working Table (mm):

-

2000

-

Slider Stroke (mm):

-

200 mm

-

Throat Depth (mm):

-

400 mm

-

Width of Working Table (mm):

-

2500 mm

-

Dimension:

-

4500*2800*2800mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ZHENGHENG

-

Year:

-

new

-

Weight (KG):

-

14000

-

Motor Power (kw):

-

30 kw

-

Marketing Type:

-

New Product 2024

-

Warranty of core components:

-

2 years

-

Maximum diagonal length of sheet:

-

2400mm

-

Max folding:

-

2000mm

-

Max folding height:

-

165mm

-

Max Stainless steel thickness:

-

1.2mm

-

Max Al Alloy thickness:

-

3mm

-

Max Mild steel thickness:

-

2mm

-

Min.sheet thickness:

-

0.5mm

-

Servo axis:

-

13

The whole machine is designed and produced according to the standard of high precision machine tool. The main body adopts steel plate welding parts, adopts strict stress elimination process, and carries out integrated processing of high precision machine tool. Finally, high precision detector is strictly checked to ensure the accuracy, stability and high rigidity of the machine for long-term operation.

Panel bender features

1. Full-touch man-machine operation interface, powerful CNC system

2. Mechanical servo reliable clamping, flexible positioning device, strong adaptability

3. Simple style of appearance design, beautiful and generous

4. Energy saving, environmental protection, low energy consumption, low noise

— Productivity is maximized without a skilled operator. compared with manual bending machine and mechanical bending machine, it can reduce labor costs and increase benefits

— Excellent bending accuracy and surface quality, as well as high repeatability, especially suitable for multi-variety, real-time, lean production

— Relative to manual bending machine close processing, this product only needs to be processed parts from the external workbench transmission, to ensure the safety of operators

— The maintenance cost is 65% lower than that of the traditional hydraulic bending machine

— Energy consumption and CO2 emissions are reduced by 64% compared to hydraulic solutions

FABRICATION TECHNOLOGY OF CNC PANEL BENDER

* In the whole welding process using carbon dioxide protection welding, welding using full welding process, to ensure that the welding workpiece firm and beautiful.

Welding support table, using high precision temperature control furnace, according to the corresponding temperature curve of the material for multiple tempering, annealing and other heat treatment process, and then for a long time full frequency vibration aging treatment, release the internal stress of the workpiece, long-term use without deformation.

* According to different workpiece design of different fixture, using high-precision multi-axis machining center to finish the workpiece, to ensure the consistency of the accuracy before and after clamping.

* Using high precision micrometer U table, with a long service life of the marble platform and marble square feet, for each workpiece accurate measurement, strict control of the processing quality of each workpiece, layer by layer check, so that the assembly accuracy of the machine meets the high precision machine tool standards.