Since Pultruded gratings are manufactured by pulling and assembling load bars and positioning those bars as needed to create panels as required, in addition to our standard panel sizes, we are able to reduce the waste material by manufacturing custom panels to size. We pultrude load bar lengths as required and assemble panels to required widths. There is no need to manufacture a full panel and waste material. In addition, we are able to custom manufacture panels of various sizes and standard styles.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Longtime

-

Model Number:

-

LTGT-35

-

Surface Treatment:

-

Gritted,Concave,Smooth,Solid-covered

-

Product name:

-

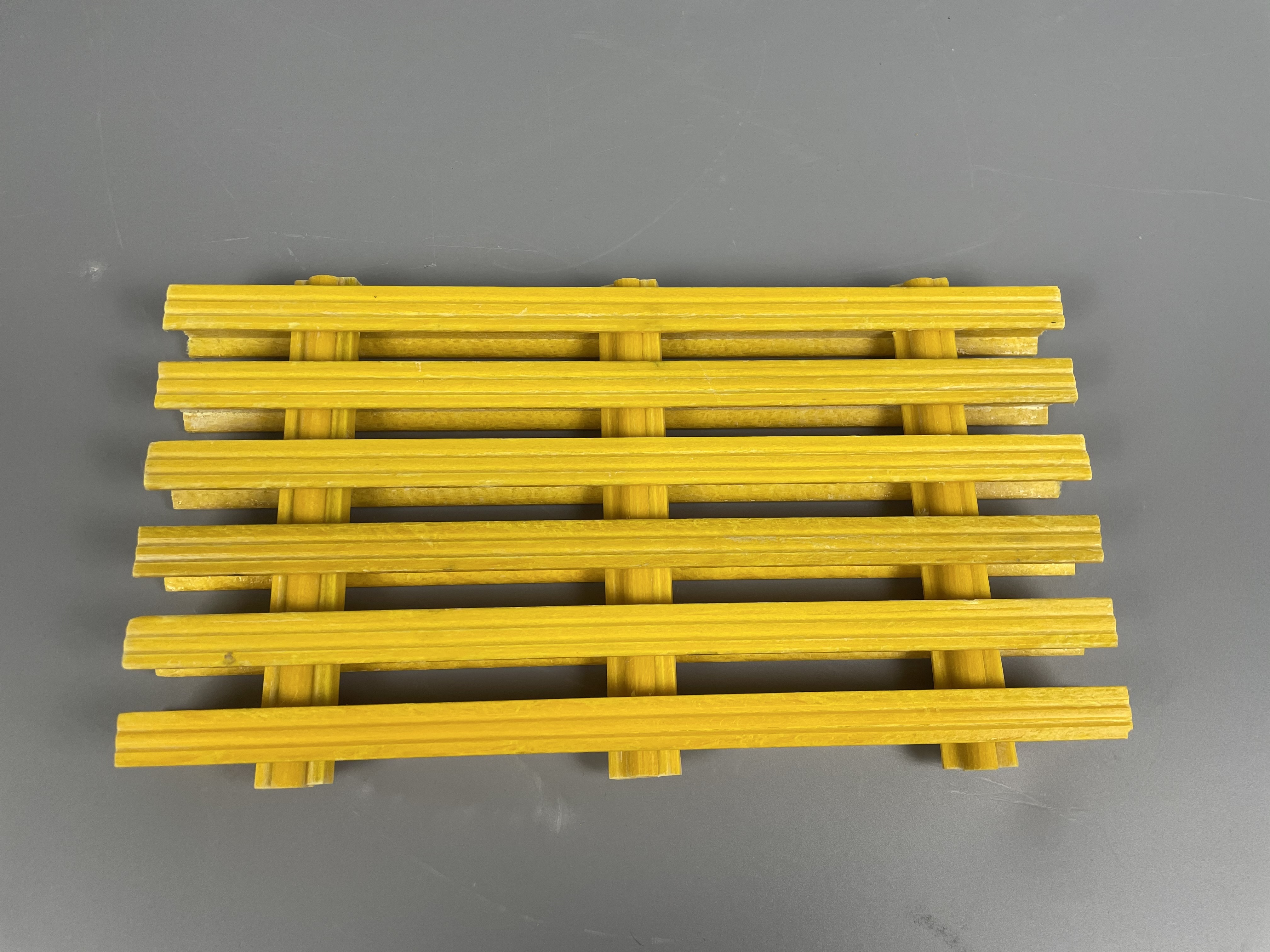

FRP Pultrusion Grating, FRP Grille

-

Material:

-

Fiberglass Reinforced Plastic

-

Advantage:

-

High Chemical Corrosion Resistant

-

Certificate:

-

ISO9001

-

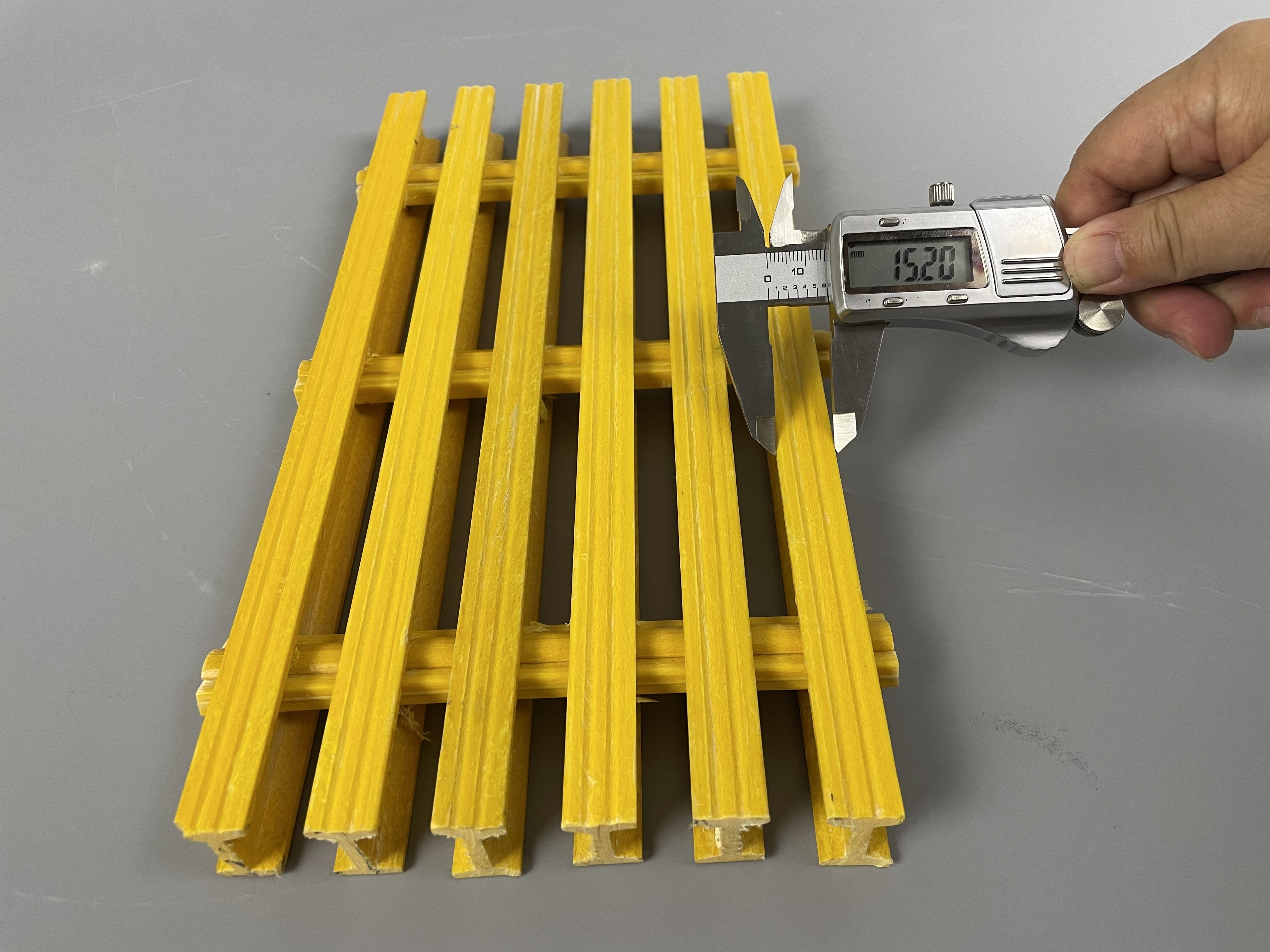

Thickness:

-

15mm/20mm/25mm/30mm/38mm or Custom

-

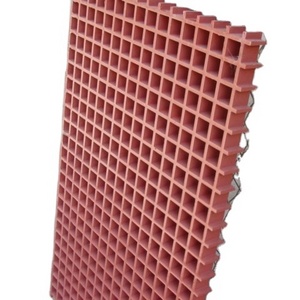

Mesh size:

-

38*38mm/40*40mm/50*50mm

-

Size:

-

1220*4025mm/1220*3660mm etc.

-

Colors:

-

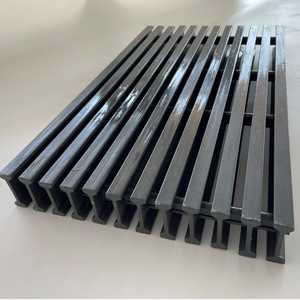

Black, Grey, Green, Blue, Yellow, etc.

-

Usage:

-

Environmental Protection, Industral, Household

-

Keywords:

-

Pultruded fiberglass Grating, I-beam Garting

Quick Details

-

Application:

-

Walkway,Platform, Chemical plant

-

Technique:

-

Molded pressing, High-temp Membrane Pressure

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Longtime

-

Model Number:

-

LTGT-35

-

Surface Treatment:

-

Gritted,Concave,Smooth,Solid-covered

-

Product name:

-

FRP Pultrusion Grating, FRP Grille

-

Material:

-

Fiberglass Reinforced Plastic

-

Advantage:

-

High Chemical Corrosion Resistant

-

Certificate:

-

ISO9001

-

Thickness:

-

15mm/20mm/25mm/30mm/38mm or Custom

-

Mesh size:

-

38*38mm/40*40mm/50*50mm

-

Size:

-

1220*4025mm/1220*3660mm etc.

-

Colors:

-

Black, Grey, Green, Blue, Yellow, etc.

-

Usage:

-

Environmental Protection, Industral, Household

-

Keywords:

-

Pultruded fiberglass Grating, I-beam Garting

Product Description

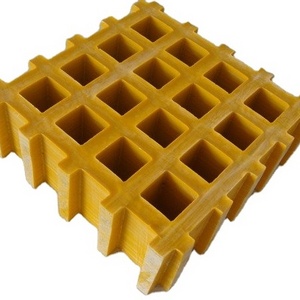

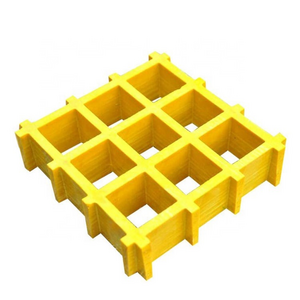

FRP I Beam Bar Grating Fiberglass Reinforced Plastics Pultruded Grating GRP Pultrusion Grating

Pultruded FRP Gratings are assembled from pultruded shapes. These shapes (I-Bars, T-Bars, etc.) are manufactured by pulling fiberglass rovings and mats through guides, then into a resin bath, then wrapped with a surfacing veil, then finally pulled through a heated die to form the desired bar shape. Once the bars are pulled, they are drilled for crossrods, then assembled by installing the crossrods spaced on 3” or 6” centers (depending on the grating type). These crossrods, that lock the bars into place, are then bonded with epoxy to ensure the bars will not move.

|

Product Name

|

FRP I Beam Bar Grating Fiberglass Reinforced Plastics Pultruded Grating GRP Pultrusion Grating

|

|

|

|

|||

|

Material

|

ECR Glass Fiber + Resin (ORTHO,ISO,VE,PHENOLIC)+Filling (ATH)

|

|

|

|

|||

|

Height

|

25mm, 32mm, 38mm, 50mm, 70mm

|

|

|

|

|||

|

Open Area

|

12%, 18%, 30% 40%, 50%, 60%

|

|

|

|

|||

|

Color

|

According to RAL Book.Yellow, Orange, Blue, Green, Grey, etc. can be cutomized

|

|

|

|

|||

|

Surface

|

Gritted, Smooth, Solid Top Covered

|

|

|

|

|||

Detailed Images

FRP I Beam Bar Grating Fiberglass Reinforced Plastics Pultruded Grating GRP Pultrusion Grating

|

Resin System

|

|

|

||

|

Resin Type

|

Corrosion resistance

|

Description

|

||

|

ORTHO

|

Moderate

|

Moderate corrosion resistance and fire retardant

|

||

|

ISO

|

Very Good

|

Industrial grade corrosion resistance and fire retardant

|

||

|

VE

|

Excellent

|

Superior corrosion resistance and fire retardant

|

||

|

Roving System

|

|

|

||

|

Item

|

Roving Type

|

Description

|

||

|

E

|

E-glass

|

Industrial grade corrosion resistance and fire retardant

|

||

|

C

|

C-glass

|

economy,good corrosion resistance but low loading strength compared to E

|

||

|

Filler System

|

|

|

||

|

Item

|

Filler

|

Description

|

||

|

ATH

|

Aluminium Hydroxide

|

anti-fire,smoke suppression,anti-corrosion

|

||

|

CAO

|

Calcium Carbonate

|

economy compared to ATH,without anti-fire requirement

|

||

|

PR

|

Pure Resin

|

Excellent in corrosion resistance

|

||

FRP I Beam Bar Grating Fiberglass Reinforced Plastics Pultruded Grating GRP Pultrusion Grating

Pultruded Fiberglass Grating Process:

During the putrusion process, a caterpilla-like machine grips the raw materials and "pulls" them through a series of steps until the finished profiles reach the cut-off saw.

Fiberglass roving and mat is pulled through guides on an automated and continuous cycle. Next, the profile receives a resin bath. Then, it is wrapped with a surface veil before being pulled through a heated die. The final task is to assemble the load bearing bars, groove and notch rod. The bearing bars are drilled on centers along the length and the cross rods are inserted and secured with epoxy perpendicularly to the bearing bar to form panels.

The reason fiberglass grating is so strong is that the material has a high glass-to-resin ratio as previously mentioned. This increases the load rating and the stiffness of the grating, making it highly valuable in industrial settings.

This type of FRP grating offers builders a wide variety of panel sizes, and flexibility because it is assembled and not molded.This helps to reduce waste, or scraps of FRP in comparison to the molded fiberglass grating process.

FRP I Beam Bar Grating Fiberglass Reinforced Plastics Pultruded Grating GRP Pultrusion Grating

Surface types:

Concave Surface (meniscus profile) – This is how the grating comes naturally out of the mold. The raised edges form a lip which

offers slip resistance.

Grit Surface – Excellent slip resistant surface.

Standard Grit - Most commonly used.

Smooth Surface – Great for Bar Screens at Wastewater Treatment plants or Architectural applications.

Concave Surface (meniscus profile) – This is how the grating comes naturally out of the mold. The raised edges form a lip which

offers slip resistance.

Grit Surface – Excellent slip resistant surface.

Standard Grit - Most commonly used.

Smooth Surface – Great for Bar Screens at Wastewater Treatment plants or Architectural applications.

Advantage

FRP I Beam Bar Grating Fiberglass Reinforced Plastics Pultruded Grating GRP Pultrusion Grating

2. Strength: 2 to 3 times stronger than molded grating, suitable for wide support span, carry great load bearing.

3. Impact resistance: The 65% glass to 35% resin ratio of pultruded grating provides twice the stiffness of molded grating, high

ultimate strength prevents impact damage.

Applications

FRP I Beam Bar Grating Fiberglass Reinforced Plastics Pultruded Grating GRP Pultrusion Grating

Industrial areas:

such as chemical plants / plating plant operating platform, maintenance platform,photovoltaic power generation platform walkway

Sewage treatment areas:

sewage treatment plant aisle and sealing cover

Municipal Engineering areas: Pedestrian Walkway, Trench / Cable Trench Cover, Tree Grating, Marine Boat decks or bridge materials,Offshore oil platform

Other civilian areas: such as car washing, cattle and sheep farms and so on.

Municipal Engineering areas: Pedestrian Walkway, Trench / Cable Trench Cover, Tree Grating, Marine Boat decks or bridge materials,Offshore oil platform

Other civilian areas: such as car washing, cattle and sheep farms and so on.

FRP I Beam Bar Grating Fiberglass Reinforced Plastics Pultruded Grating GRP Pultrusion Grating

Packing & Delivery

FRP I Beam Bar Grating Fiberglass Reinforced Plastics Pultruded Grating GRP Pultrusion Grating

Packaging Details: Wooden pallet,carton,wooden case and we can also as customer's request

Delivery Detail: Within 20 days after receiving the advanced payment

Certifications

FAQ

Q: How can you guarantee your product quality?

A: 100% of our products will be tested before delivery. To control quality, we are using high quality material from high quality supplier.

Q: Are you a trading company or a manufacturing factory?

A:We are a manufacturing factory with export qualifications. Our factory is one of the Best FRP products manufacturer in China since 2014.We have FRP products of high quality and various kinds.

Q: I am interested in your products, could I get sample for free?

A: We could supply a few pieces of FREE samples if we have some in stock. All you need to do is kindly offering your shipping account.

Q:

Can you do the design for us?

A: Yes. With experienced teams in fiberglass product design and manufacturing, we can provide customized shape,dimension, colors service.

Hot Searches