- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

1.5KW

-

Weight:

-

760 KG

-

Dimension(L*W*H):

-

1195*1120*1720mm

-

Product name:

-

Food Sterilizer for Garlic Powder/Slice and Dehydrated Onions

-

Design Temperature:

-

139℃

-

Working Temperature:

-

134℃

-

Compressed Air Pressure:

-

0.6-0.8Mpa

-

Tap Water Pressure:

-

0.2-0.3Mpa

-

Vacunm:

-

-0.095Mpa

-

Working Pressure:

-

0.22Mpa

-

Steam Pressure:

-

0.4-0.6Mpa

-

Certificates:

-

CE ISO

-

Application:

-

Garlic Powder/Slice and Dehydrated Onions

Quick Details

-

Marketing Type:

-

Hot Product 2023

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ROOETECH

-

Voltage:

-

380V

-

Power:

-

1.5KW

-

Weight:

-

760 KG

-

Dimension(L*W*H):

-

1195*1120*1720mm

-

Product name:

-

Food Sterilizer for Garlic Powder/Slice and Dehydrated Onions

-

Design Temperature:

-

139℃

-

Working Temperature:

-

134℃

-

Compressed Air Pressure:

-

0.6-0.8Mpa

-

Tap Water Pressure:

-

0.2-0.3Mpa

-

Vacunm:

-

-0.095Mpa

-

Working Pressure:

-

0.22Mpa

-

Steam Pressure:

-

0.4-0.6Mpa

-

Certificates:

-

CE ISO

-

Application:

-

Garlic Powder/Slice and Dehydrated Onions

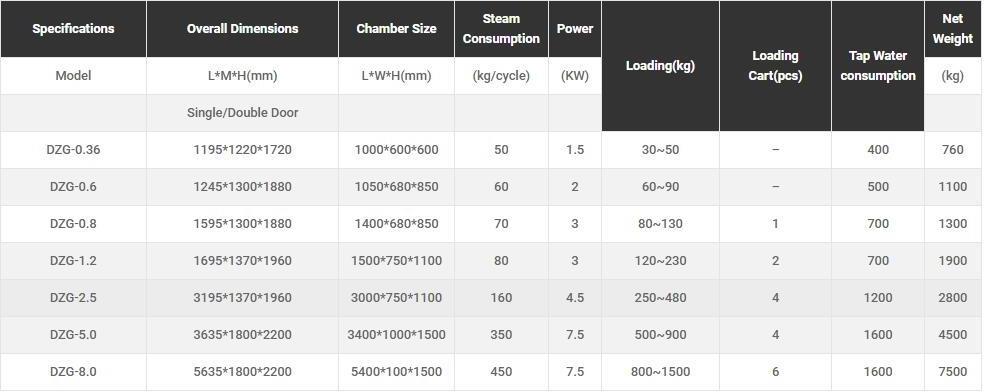

DZG Series Steam Sterilization Equipment Food Sterilizer for Garlic Powder/Slice and Dehydrated Onions

Description:

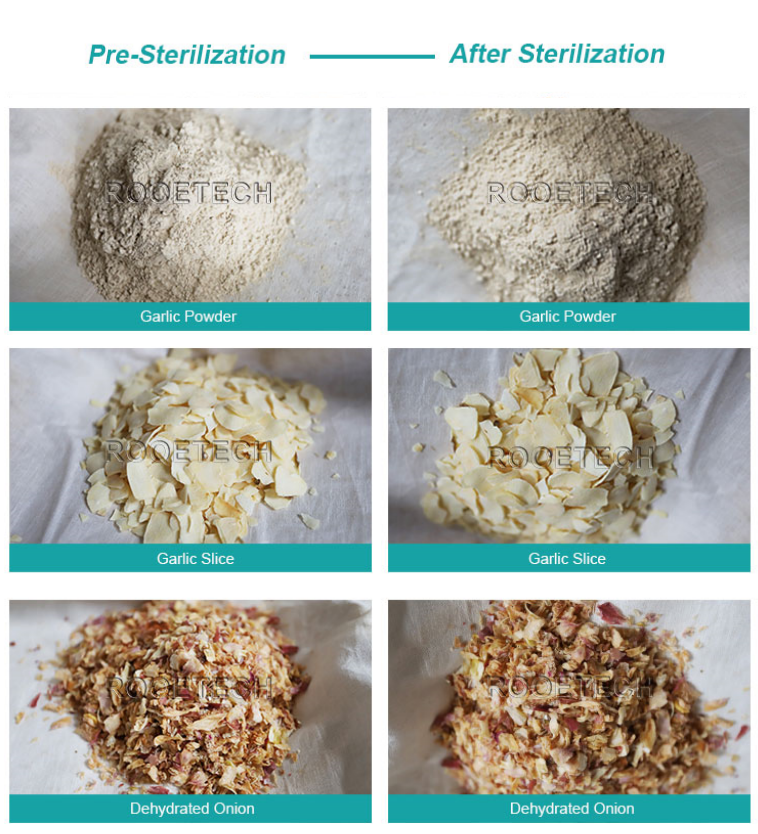

Garlic has high edible value and medicinal value. As a common condiment, it can be sliced, dried, ground and so on. At present, the edible and medicinal value of garlic is increasing, and the market demand is also increasing.Use autoclave steam sterilizer to preserve original flavor and extend shelf life. The shelf life of dehydrated products compared to fresh ingredients may be the biggest advantage for food manufacturers.

Features:

Saturated water vapor is used as the sterilization medium of pulsating vacuum sterilizer, and the air removal method of pulsating vacuum is adopted. Through the alternating action of three to four times pumping vacuum and injecting steam, the air is forced to empty the inner room, so that the air exclusion exceeds 99%, the cold point in the sterilization room is completely eliminated, and the temperature “dead Angle” is completely eliminated. Microbial proteins are denatured, solidified and inactivated under the action of high temperature and high pressure to achieve the purpose of sterilization. The vacuum dehumidification and reuse of the sterilizer jacket are dried at a high temperature of 132-134 degrees Celsius, so that the sterilized items are kept clean and dry to ensure that the hands are neither hot nor wet when taking out the items.

1. the temperature has a better uniformity, the degree of damage is also light.

2. so that energy, manpower and material resources are saved.

3. can be completely sterilized.

4. with high working efficiency and short sterilization cycle.

5. Energy can be saved.

| Design pressure | Working Pressure | Design Temperature | Working Temperature | Heat Equilibrium | Vacuum | Steam Source Pressure | Water Source Pressure | Compressed Air Pressure |

|

0.245 Mpa |

0.22 Mpa |

139 ℃ |

134 ℃ |

≤±1 ℃ |

-0.095 Mpa |

0.4-0.6 Mpa |

0.2-0.3 Mpa |

0.6-0.8 Mpa |

Optional:

Remote monitoring system

CIP Washing Function:

Ensure the quality of the final product and meet stringent hygiene requirements. The CIP program cleans dirt while also killing microorganisms inside the equipment. With an automated and well-designed monitoring system, better cleaning results are guaranteed to ensure the production of consistently high quality products.

Test Report: