- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-1.0mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZTRFM

-

Voltage:

-

AC380V 50Hz 3 Phase

-

Dimension(L*W*H):

-

6.5*0.8*1.2m

-

Weight:

-

5500 kg

-

Feeding width:

-

116mm

-

Marketing Type:

-

New Product

-

Advantage:

-

Easy installation and operation

-

After-sales Service:

-

Provided Lifetime technical service

-

Local service:

-

Provide Engineers door-to-door service

-

Certification:

-

CE ISO

-

Raw material:

-

PPGI,PPGL

-

Diameter of shafts:

-

50 mm

-

Material of shafts:

-

45# steel with tempering

-

Number of rollers:

-

10 rollers+10 rollers

-

Material of blades:

-

Cr12 quenched

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Glaze Steel

-

Production Capacity:

-

25 M/min

-

Rolling thinckness:

-

0.3-1.0mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZTRFM

-

Voltage:

-

AC380V 50Hz 3 Phase

-

Dimension(L*W*H):

-

6.5*0.8*1.2m

-

Weight:

-

5500 kg

-

Feeding width:

-

116mm

-

Marketing Type:

-

New Product

-

Advantage:

-

Easy installation and operation

-

After-sales Service:

-

Provided Lifetime technical service

-

Local service:

-

Provide Engineers door-to-door service

-

Certification:

-

CE ISO

-

Raw material:

-

PPGI,PPGL

-

Diameter of shafts:

-

50 mm

-

Material of shafts:

-

45# steel with tempering

-

Number of rollers:

-

10 rollers+10 rollers

-

Material of blades:

-

Cr12 quenched

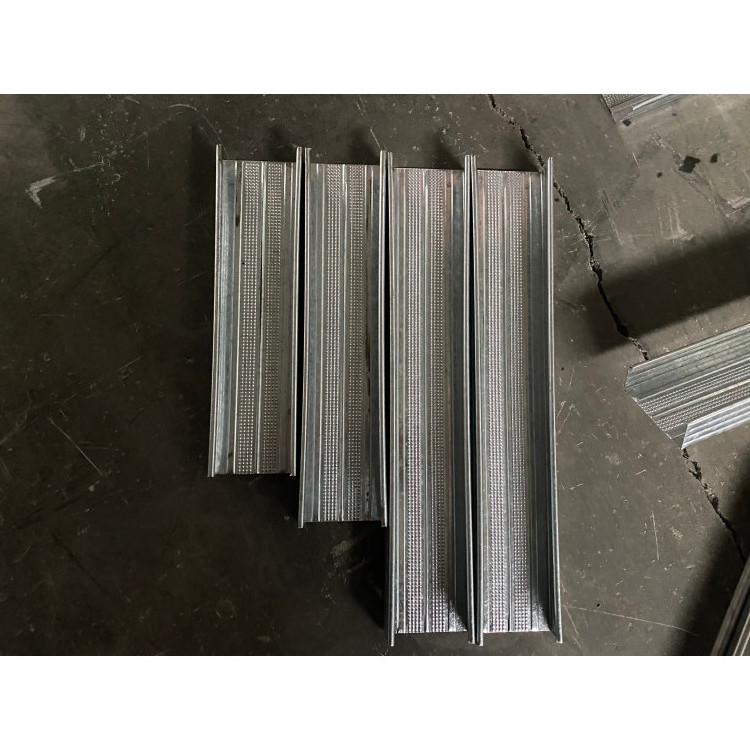

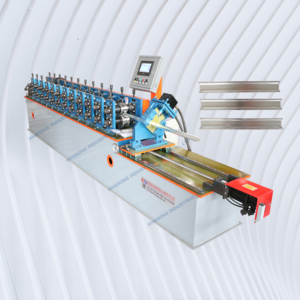

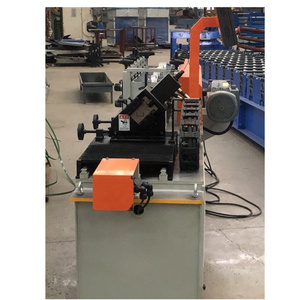

Double Line Keel Roll Forming Machine

Design Idea:

High speed: 0-25 m per minute

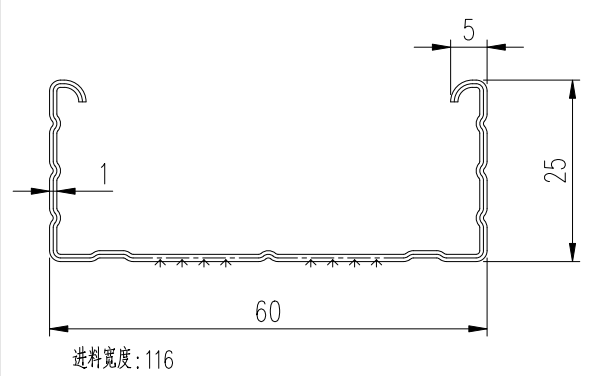

Profile drawing for reference:

Raw Material Thickness

0.3-1.0mm

Processing Flow

Decoiling → Feeding → Roll forming → Cutting → Run out table

|

Double Line Keel Roll Forming Machine

|

|

|

|

|||

|

ITEM

|

|

Parameter

|

Memo

|

|||

|

Raw material

|

Type

|

GI and GL

|

|

|||

|

Forming speed

|

Thickness

|

0.3-1.0mm

|

|

|||

|

Forming stations

|

Width

|

116mm / 72mm

|

|

|||

|

Forming Speed (m/min)

|

|

About 25

|

Excluding cutting time

|

|||

|

Total power(KW)

|

|

14kw

|

Depend on actual design

|

|||

|

Power

|

|

AC380V 50Hz 3 Phase

|

Decided by customer

|

|||

5T manual decoiler

Parameters

Loading capacity:≤1.5T

Coil inner diameter:Ø450-550mm

Qty:2 sets

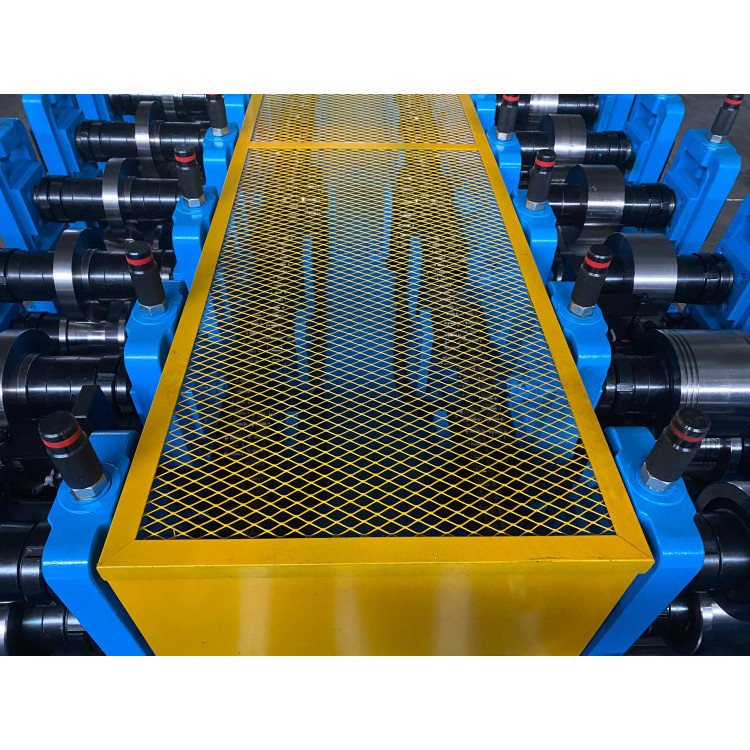

Main roll forming machine

Main part:4500х 1700х 1500mm (L*W*H)

Frame type:Molding frame

Drive mode:Gear

Material of rollers:GCr12mov

Material of shafts:5# steel with tempering

The shaft diameters;φ 50 mm

Number of rollers:10 rollers+10 rollers

Main power:4 kw + 4 kw

Machine running speed:25m per min

Post Cutting Device

Material of blades: Cr12 quenched

Power supply : Hydraulic power

Components: It contains one set of blade, one hydraulic tank and one cutter machine.

Stacker

Electrical Control System

Our PLC system adopts Taiwan delta brand.

When machine arrives to you, simple plug in and out. All installation could be finished within half an hour.

Language:Chinese and English or as customized

Voltage:380V 50Hz 3 Phase (as customer request)

Length measurement:Automatically controlled by PLC

Quantity measurement:Automatically controlled by PLC

Length Tolerance:3m±1.5mm

Operating panel:Touching screen and button together

Brand of PLC:Delta (Taiwan)

Low voltage electrical apparatus:Schneider

Counter:OMRON

Hydraulic system

No. 4Q230524.CZIDW03

ISO 9001(No:ZL92090220234630)

Hot Searches